Spring steel offers exceptional elasticity and tensile strength, making it ideal for applications requiring repeated flexing and shock resistance. Mild steel, characterized by its low carbon content, is easier to weld and machine but lacks the high resilience of spring steel. The choice between them depends on the need for durability under stress versus ease of fabrication and cost-effectiveness.

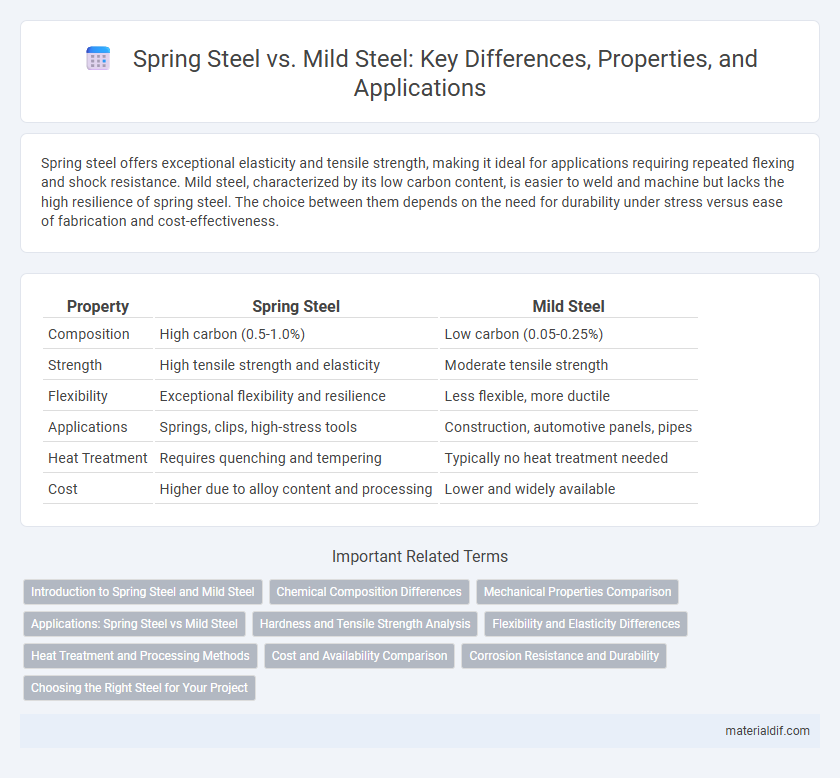

Table of Comparison

| Property | Spring Steel | Mild Steel |

|---|---|---|

| Composition | High carbon (0.5-1.0%) | Low carbon (0.05-0.25%) |

| Strength | High tensile strength and elasticity | Moderate tensile strength |

| Flexibility | Exceptional flexibility and resilience | Less flexible, more ductile |

| Applications | Springs, clips, high-stress tools | Construction, automotive panels, pipes |

| Heat Treatment | Requires quenching and tempering | Typically no heat treatment needed |

| Cost | Higher due to alloy content and processing | Lower and widely available |

Introduction to Spring Steel and Mild Steel

Spring steel, a high-carbon steel known for its exceptional elasticity and tensile strength, is engineered to withstand significant deformation without permanent distortion, making it ideal for applications requiring repeated bending or twisting. Mild steel, characterized by its low carbon content typically less than 0.3%, offers excellent weldability, ductility, and machinability but lacks the resilience and tensile strength of spring steel. Both steels serve distinct purposes: spring steel excels in producing durable springs and high-stress components, while mild steel is favored in structural and general-purpose fabrication due to its versatility and cost-effectiveness.

Chemical Composition Differences

Spring steel contains a higher percentage of carbon, typically between 0.5% to 1.0%, enhancing its hardness and elasticity, while mild steel has a lower carbon content, usually around 0.05% to 0.25%, making it more ductile and malleable. The elevated levels of manganese (about 0.7% to 1.2%) in spring steel improve tensile strength and fatigue resistance, which are significantly lower in mild steel. Unlike mild steel, spring steel often includes small amounts of silicon and other alloying elements to optimize its performance under repeated stress.

Mechanical Properties Comparison

Spring steel exhibits high tensile strength and excellent elasticity, making it ideal for applications requiring flexibility and resistance to deformation under repeated stress. Mild steel, with lower carbon content, offers greater ductility and weldability but has reduced tensile strength and hardness compared to spring steel. The superior yield strength and fatigue resistance of spring steel enable it to maintain performance in dynamic or cyclical load environments, whereas mild steel is better suited for structural uses with less mechanical strain.

Applications: Spring Steel vs Mild Steel

Spring steel is widely used in applications requiring high yield strength and flexibility, such as automotive suspension components, springs, and high-tension wires. Mild steel, known for its ductility and weldability, is commonly applied in construction frames, automotive body panels, and structural components. The choice between spring steel and mild steel depends on the need for elasticity versus ease of fabrication in various industrial applications.

Hardness and Tensile Strength Analysis

Spring steel exhibits higher hardness and tensile strength compared to mild steel, making it ideal for applications requiring durability and elasticity under repeated stress. Typically, spring steel has a tensile strength ranging from 750 to 2000 MPa, whereas mild steel ranges between 400 to 550 MPa, reflecting its superior resistance to deformation. This enhanced mechanical performance is due to the high carbon content and heat treatment processes used in manufacturing spring steel.

Flexibility and Elasticity Differences

Spring steel exhibits superior flexibility and elasticity compared to mild steel, making it ideal for applications requiring repeated bending and stress recovery. The high carbon content and alloying elements in spring steel enhance its ability to return to its original shape without permanent deformation. Mild steel, with lower carbon content, offers less elasticity and flexibility, leading to easier plastic deformation under stress.

Heat Treatment and Processing Methods

Spring steel undergoes specialized heat treatment processes such as quenching and tempering to enhance its elasticity, tensile strength, and fatigue resistance, making it ideal for applications requiring high resilience. Mild steel, on the other hand, experiences simpler processing methods like annealing and normalizing to improve ductility and machinability but lacks the high tensile strength seen in spring steel. The precise control of temperature and cooling rates in spring steel's heat treatment significantly impacts its microstructure, resulting in a hardened material capable of returning to its original shape under stress.

Cost and Availability Comparison

Spring steel typically costs more than mild steel due to its higher carbon content and specialized heat treatment process, which enhances its strength and flexibility. Mild steel is widely available and generally cheaper, making it a cost-effective choice for applications requiring less tensile strength and flexibility. The availability of mild steel in various grades and forms also contributes to its lower price and ease of procurement compared to spring steel.

Corrosion Resistance and Durability

Spring steel exhibits superior corrosion resistance and durability compared to mild steel due to its higher carbon content and alloying elements like silicon and manganese. These properties enable spring steel to withstand repeated stress and resist rusting in harsh environments, making it ideal for applications requiring high fatigue strength and longevity. Mild steel, with lower carbon content and minimal alloying, is more susceptible to corrosion and wear, necessitating protective coatings for enhanced durability.

Choosing the Right Steel for Your Project

Spring steel offers high yield strength and excellent elasticity, making it ideal for applications requiring flexibility and resistance to deformation, such as springs and clips. Mild steel provides superior ductility and weldability, suitable for structural components and general fabrication where high strength is not critical. Selecting the right steel depends on load requirements, flexibility needs, and the specific environmental conditions of the project.

Spring Steel vs Mild Steel Infographic

materialdif.com

materialdif.com