Mild steel contains a low carbon content, typically around 0.05% to 0.25%, making it softer, more ductile, and easier to weld or shape, ideal for construction and automotive parts. High-carbon steel has a higher carbon content, usually between 0.6% and 1.0%, which increases hardness and strength but reduces ductility, making it suitable for cutting tools and high-strength applications. Choosing between mild steel and high-carbon steel depends on the required balance of strength, flexibility, and wear resistance for the specific steel pet product.

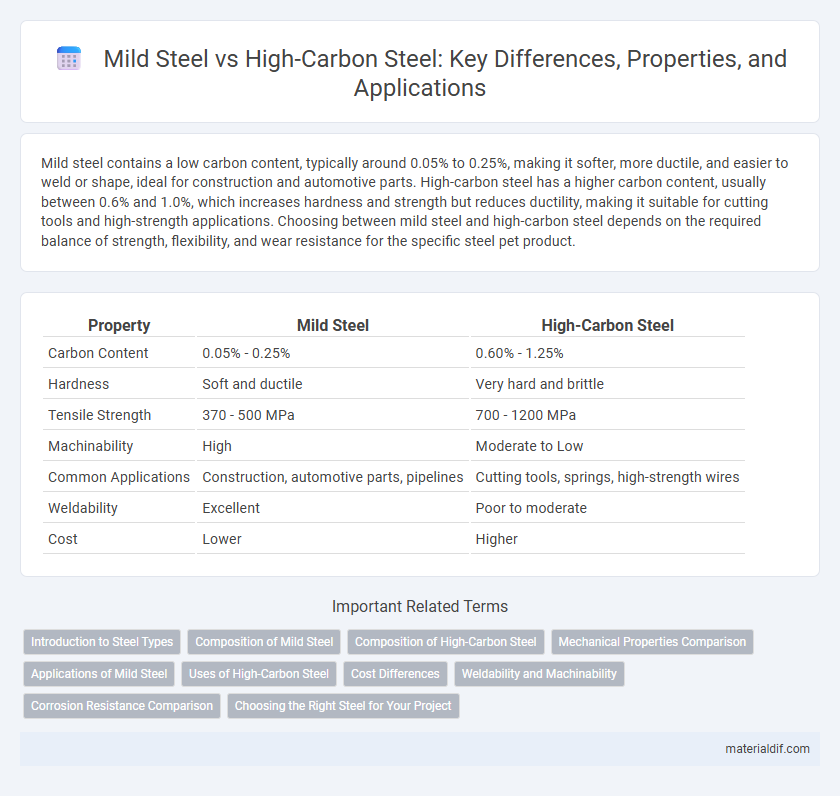

Table of Comparison

| Property | Mild Steel | High-Carbon Steel |

|---|---|---|

| Carbon Content | 0.05% - 0.25% | 0.60% - 1.25% |

| Hardness | Soft and ductile | Very hard and brittle |

| Tensile Strength | 370 - 500 MPa | 700 - 1200 MPa |

| Machinability | High | Moderate to Low |

| Common Applications | Construction, automotive parts, pipelines | Cutting tools, springs, high-strength wires |

| Weldability | Excellent | Poor to moderate |

| Cost | Lower | Higher |

Introduction to Steel Types

Mild steel contains approximately 0.05% to 0.25% carbon, making it softer, more ductile, and easier to weld compared to high-carbon steel, which has carbon content ranging from 0.6% to 1.0%. High-carbon steel offers greater hardness and tensile strength but sacrifices some malleability and weldability. Understanding the carbon content and its effects on mechanical properties is essential for selecting the appropriate steel type for construction, manufacturing, and tooling applications.

Composition of Mild Steel

Mild steel primarily contains approximately 0.05% to 0.25% carbon, making it softer and more ductile compared to high-carbon steel, which typically has 0.6% to 1.0% carbon content. The low carbon concentration in mild steel results in enhanced weldability and machinability, ideal for structural applications and automotive parts. In contrast, high-carbon steel's composition provides greater hardness and tensile strength but reduces flexibility and increases brittleness.

Composition of High-Carbon Steel

High-carbon steel contains approximately 0.6% to 1.0% carbon, which significantly increases its hardness and strength compared to mild steel, typically having 0.05% to 0.25% carbon. The elevated carbon content in high-carbon steel also enhances wear resistance but reduces ductility and weldability. This composition makes high-carbon steel ideal for cutting tools, springs, and high-strength wires.

Mechanical Properties Comparison

Mild steel exhibits lower tensile strength and hardness, typically ranging from 370 to 700 MPa, making it more ductile and easier to weld compared to high-carbon steel, which has tensile strengths between 800 to 1000 MPa and higher hardness values. High-carbon steel offers superior wear resistance and tensile strength due to its carbon content of 0.6% to 1.0%, but this also reduces its ductility and toughness. The distinct mechanical properties dictate their applications, with mild steel favored for structural uses and high-carbon steel preferred for tools and cutting instruments.

Applications of Mild Steel

Mild steel is extensively used in construction, automotive manufacturing, and structural components due to its excellent weldability and ductility. It serves in the production of pipelines, bridges, and shipbuilding where moderate strength and machinability are essential. The versatility of mild steel makes it ideal for household appliances, furniture, and general fabrication tasks requiring cost-effective material.

Uses of High-Carbon Steel

High-carbon steel is predominantly used in applications requiring high strength, hardness, and wear resistance, such as cutting tools, blades, springs, and high-strength wires. Its superior carbon content, typically between 0.6% and 1.0%, enhances durability and edge retention, making it ideal for saw blades, knives, and drill bits. High-carbon steel also finds critical use in automotive parts and heavy-duty machinery components where toughness and performance under stress are essential.

Cost Differences

Mild steel typically costs less than high-carbon steel due to its lower carbon content and simpler manufacturing process, making it an economical choice for general construction and fabrication. High-carbon steel incurs higher expenses because of its enhanced hardness and strength, requiring more complex alloying and heat treatment techniques. The cost difference impacts material selection based on application needs, balancing budget constraints with performance requirements.

Weldability and Machinability

Mild steel offers superior weldability due to its lower carbon content, resulting in less brittleness and reduced risk of cracking during welding processes compared to high-carbon steel. High-carbon steel, with its increased hardness, presents challenges in weldability, often requiring preheating and controlled cooling to avoid weld defects. When it comes to machinability, mild steel is easier to machine, allowing for faster cutting speeds and longer tool life, whereas high-carbon steel demands more robust tooling and slower machining rates to handle its hardness and wear resistance.

Corrosion Resistance Comparison

Mild steel exhibits lower corrosion resistance compared to high-carbon steel due to its lower carbon content and fewer alloying elements that enhance durability. High-carbon steel's increased carbon levels contribute to a stronger and harder material but also make it more susceptible to rust without proper protective coatings. Protective treatments like galvanization or painting are essential for both steels to prevent oxidation and extend their service life in corrosive environments.

Choosing the Right Steel for Your Project

Mild steel contains approximately 0.05-0.25% carbon, offering excellent ductility and weldability ideal for structural and automotive applications. High-carbon steel, with 0.6-1.0% carbon, provides superior hardness and tensile strength, making it suitable for cutting tools and high-wear components. Selecting the appropriate steel depends on balancing ductility, strength, and machinability based on specific project requirements.

Mild Steel vs High-carbon Steel Infographic

materialdif.com

materialdif.com