Ferritic steel offers excellent corrosion resistance and good weldability, making it ideal for automotive and industrial applications where magnetic properties are beneficial. Duplex steel combines the advantages of ferritic and austenitic steels, providing superior strength and enhanced resistance to stress corrosion cracking. Choosing between ferritic and duplex steel depends on the required mechanical performance and environmental exposure.

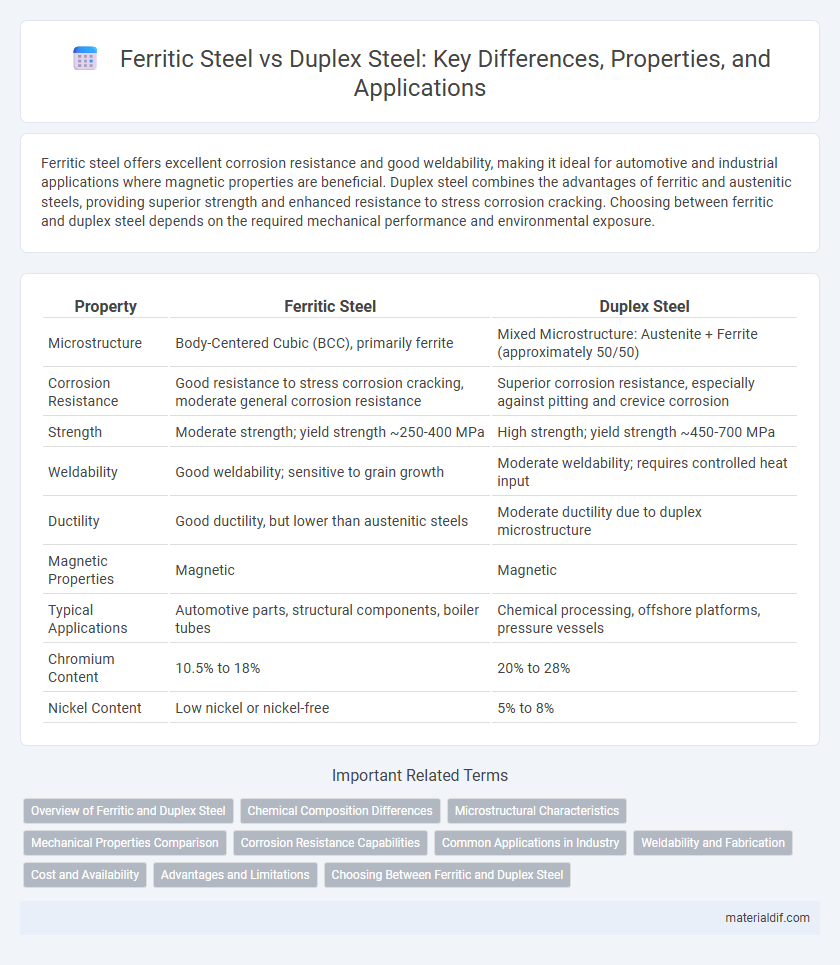

Table of Comparison

| Property | Ferritic Steel | Duplex Steel |

|---|---|---|

| Microstructure | Body-Centered Cubic (BCC), primarily ferrite | Mixed Microstructure: Austenite + Ferrite (approximately 50/50) |

| Corrosion Resistance | Good resistance to stress corrosion cracking, moderate general corrosion resistance | Superior corrosion resistance, especially against pitting and crevice corrosion |

| Strength | Moderate strength; yield strength ~250-400 MPa | High strength; yield strength ~450-700 MPa |

| Weldability | Good weldability; sensitive to grain growth | Moderate weldability; requires controlled heat input |

| Ductility | Good ductility, but lower than austenitic steels | Moderate ductility due to duplex microstructure |

| Magnetic Properties | Magnetic | Magnetic |

| Typical Applications | Automotive parts, structural components, boiler tubes | Chemical processing, offshore platforms, pressure vessels |

| Chromium Content | 10.5% to 18% | 20% to 28% |

| Nickel Content | Low nickel or nickel-free | 5% to 8% |

Overview of Ferritic and Duplex Steel

Ferritic steel is a type of stainless steel characterized by a body-centered cubic (BCC) crystal structure, providing excellent resistance to stress corrosion cracking and good ductility at room temperature. Duplex steel combines austenitic and ferritic microstructures, delivering superior strength and enhanced corrosion resistance, particularly in chloride-rich environments. The balanced phase composition in duplex steel offers improved weldability and toughness compared to ferritic steel, making it suitable for demanding industrial applications.

Chemical Composition Differences

Ferritic steel primarily consists of 10-30% chromium with minimal nickel content, enhancing corrosion resistance but limiting strength and toughness. Duplex steel contains balanced amounts of austenitic and ferritic phases, typically 20-30% chromium, 4-7% nickel, and small quantities of molybdenum and nitrogen, offering superior mechanical properties and corrosion resistance. The presence of higher nickel and molybdenum in duplex steel improves pitting resistance compared to the lower alloyed ferritic steel.

Microstructural Characteristics

Ferritic steel primarily consists of a body-centered cubic (BCC) ferrite phase, which imparts good corrosion resistance and magnetic properties but lower strength compared to other steels. Duplex steel features a balanced microstructure of approximately 50% ferrite and 50% austenite, combining the toughness and weldability of austenite with the strength and stress corrosion cracking resistance of ferrite. The dual-phase microstructure in duplex steel results in superior mechanical properties, including higher yield strength and improved corrosion resistance, compared to the single-phase ferritic steel.

Mechanical Properties Comparison

Ferritic steel offers excellent corrosion resistance and good magnetic properties, with tensile strengths typically ranging from 400 to 600 MPa and lower ductility compared to duplex steel. Duplex steel combines austenitic and ferritic phases, providing superior mechanical strength, often exceeding 700 MPa tensile strength, along with enhanced toughness and better resistance to stress corrosion cracking. The heterogeneous microstructure of duplex steel results in higher yield strength and improved fatigue performance relative to the more uniform ferritic steel.

Corrosion Resistance Capabilities

Ferritic steel exhibits moderate corrosion resistance due to its high chromium content, typically ranging from 10.5% to 30%, which forms a protective oxide layer that prevents surface degradation. Duplex steel, combining austenitic and ferritic microstructures with chromium levels around 22-28% and added molybdenum, offers superior corrosion resistance, especially in chloride-rich environments, by resisting pitting and stress corrosion cracking. The enhanced hybrid microstructure in duplex steel delivers both higher strength and improved resistance to localized corrosion compared to ferritic steel.

Common Applications in Industry

Ferritic steel is commonly used in automotive components, kitchen appliances, and industrial machinery due to its excellent corrosion resistance and magnetic properties. Duplex steel is favored in chemical processing, oil and gas industries, and marine applications for its superior strength and enhanced resistance to stress corrosion cracking. Both steels are integral in manufacturing pipelines, heat exchangers, and pressure vessels where durability and corrosion resistance are critical.

Weldability and Fabrication

Ferritic steel offers moderate weldability with good resistance to stress corrosion cracking but requires careful control of heat input to avoid grain growth and embrittlement during fabrication. Duplex steel exhibits superior weldability due to its balanced microstructure of ferrite and austenite, providing enhanced strength and corrosion resistance, yet demands precise welding parameters to prevent phase imbalance and ensure optimal joint performance. Fabrication of duplex steel benefits from faster cooling rates and reduced distortion compared to ferritic steel, making it suitable for complex structures in aggressive environments.

Cost and Availability

Ferritic steel offers lower cost and higher availability due to its simpler iron-chromium composition and widespread production, making it a budget-friendly choice for large-scale applications. Duplex steel, containing balanced austenitic and ferritic phases with added nickel and molybdenum, commands higher prices and has more limited availability because of complex alloying and production requirements. Industries prioritize ferritic steel when cost efficiency and abundant supply are critical, while duplex steel is chosen for environments requiring superior corrosion resistance despite higher costs.

Advantages and Limitations

Ferritic steel offers excellent resistance to stress corrosion cracking and good thermal conductivity, making it suitable for automotive and industrial applications, though its lower strength and toughness limit its use in demanding environments. Duplex steel combines the benefits of both ferritic and austenitic structures, providing superior strength, corrosion resistance, and fatigue resistance, but it can be more expensive and challenging to weld. The choice between ferritic and duplex steel depends on the specific performance requirements and environmental conditions of the application.

Choosing Between Ferritic and Duplex Steel

Choosing between ferritic and duplex steel depends on corrosion resistance and mechanical properties required for the application. Ferritic steel offers good resistance to stress corrosion cracking and is typically less expensive, making it suitable for automotive and industrial components. Duplex steel provides superior strength and excellent resistance to pitting and crevice corrosion, ideal for chemical processing and marine environments where durability is critical.

Ferritic Steel vs Duplex Steel Infographic

materialdif.com

materialdif.com