Tempered steel undergoes a heat treatment process that enhances its strength, toughness, and resistance to impact by reducing brittleness compared to untempered steel. Untempered steel lacks this refined molecular structure, making it more prone to cracking and less durable under heavy stress. Choosing tempered steel ensures improved performance in demanding applications where durability and reliability are critical.

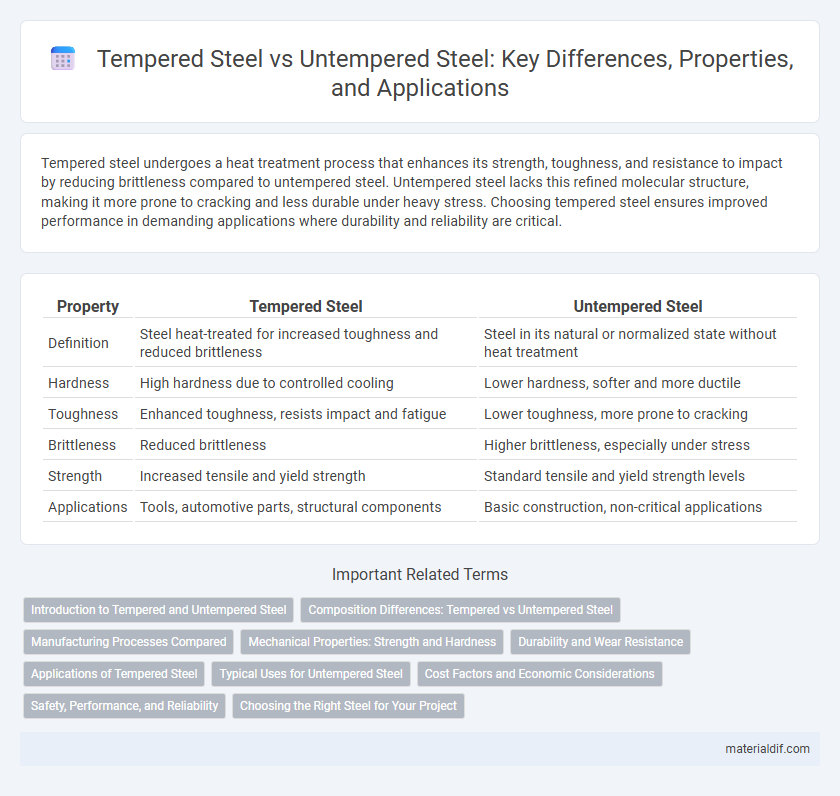

Table of Comparison

| Property | Tempered Steel | Untempered Steel |

|---|---|---|

| Definition | Steel heat-treated for increased toughness and reduced brittleness | Steel in its natural or normalized state without heat treatment |

| Hardness | High hardness due to controlled cooling | Lower hardness, softer and more ductile |

| Toughness | Enhanced toughness, resists impact and fatigue | Lower toughness, more prone to cracking |

| Brittleness | Reduced brittleness | Higher brittleness, especially under stress |

| Strength | Increased tensile and yield strength | Standard tensile and yield strength levels |

| Applications | Tools, automotive parts, structural components | Basic construction, non-critical applications |

Introduction to Tempered and Untempered Steel

Tempered steel undergoes a heat treatment process that enhances its strength, hardness, and toughness by carefully balancing hardness and ductility. Untempered steel, which has not been subjected to this controlled heat treatment, typically exhibits higher brittleness and lower impact resistance. The tempering process optimizes steel's microstructure, making tempered steel more suitable for applications requiring durability and resilience under stress.

Composition Differences: Tempered vs Untempered Steel

Tempered steel undergoes controlled heat treatment that alters its microstructure, resulting in a balanced composition of martensite and tempered pearlite, which enhances toughness and reduces brittleness. Untempered steel typically retains a higher martensitic content with more internal stresses, making it harder but more brittle due to the lack of stress relief during cooling. The chemical composition remains similar between both, but the heat treatment process significantly changes the distribution and morphology of carbon and alloying elements within the steel matrix.

Manufacturing Processes Compared

Tempered steel undergoes a precise heat treatment involving heating to a critical temperature followed by controlled cooling, which enhances its hardness and toughness by reducing brittleness. Untempered steel lacks this specific heat treatment, retaining a softer, more ductile microstructure typically resulting from standard cooling methods after forging or casting. The manufacturing process of tempered steel requires careful thermal cycling to achieve desired mechanical properties, whereas untempered steel relies mainly on its initial formation and cooling rates without additional heat treatment steps.

Mechanical Properties: Strength and Hardness

Tempered steel exhibits higher strength and hardness compared to untempered steel due to the controlled heat treatment process that refines its microstructure. The tempering process reduces brittleness while enhancing toughness, resulting in improved resistance to wear and fatigue under mechanical stress. Untempered steel tends to be softer and more ductile, making it less resistant to deformation and surface damage in demanding applications.

Durability and Wear Resistance

Tempered steel demonstrates significantly higher durability and wear resistance compared to untempered steel due to its heat treatment process, which refines the grain structure and reduces brittleness. The tempering process improves toughness by relieving internal stresses, making tempered steel less prone to cracking or breaking under mechanical stress. In contrast, untempered steel, lacking this heat treatment, exhibits lower durability and is more susceptible to wear and deformation during heavy use.

Applications of Tempered Steel

Tempered steel is extensively used in applications requiring enhanced strength, durability, and resistance to impact, such as automotive components, cutting tools, and structural parts in heavy machinery. Its heat treatment process improves toughness and reduces brittleness compared to untempered steel, making it ideal for load-bearing and high-stress environments. Industries like aerospace, construction, and manufacturing rely on tempered steel for critical components that demand reliability and longevity.

Typical Uses for Untempered Steel

Untempered steel is commonly used in structural applications where high strength and rigidity are required without the need for enhanced toughness or flexibility, such as in construction beams, metal frameworks, and industrial machinery components. It is also utilized in manufacturing automotive parts and heavy equipment where dimensional stability and hardness are critical but shock resistance is less essential. Typical uses prioritize cost-efficiency and ease of fabrication over impact resistance, making untempered steel suitable for static load-bearing roles and general-purpose fabrication.

Cost Factors and Economic Considerations

Tempered steel typically incurs higher production costs due to additional heat treatment processes that enhance hardness and durability, resulting in greater material longevity and reduced maintenance expenses. Untempered steel, while cheaper upfront, may lead to increased replacement and repair costs over time because of lower wear resistance and potential for structural failure under stress. Economic considerations favor tempered steel in applications demanding long-term performance and safety, despite its initial price premium.

Safety, Performance, and Reliability

Tempered steel offers enhanced safety due to its increased strength and controlled fracture behavior, reducing the risk of dangerous sharp shards upon breakage compared to untempered steel. Performance-wise, tempered steel provides superior hardness and durability, making it ideal for high-stress applications where impact resistance and longevity are critical. Reliability is significantly improved with tempered steel, as its heat treatment process ensures consistent mechanical properties and fatigue resistance, essential for structural and industrial components.

Choosing the Right Steel for Your Project

Tempered steel offers enhanced strength, hardness, and resistance to wear, making it ideal for high-stress applications such as automotive parts, tools, and structural components. Untempered steel, while more ductile and easier to machine, lacks the improved mechanical properties of tempered steel, which may limit its use in load-bearing or high-impact projects. Selecting the right steel depends on project requirements, balancing factors like toughness, machinability, and durability to ensure optimal performance and safety.

Tempered steel vs Untempered steel Infographic

materialdif.com

materialdif.com