Martensitic steel offers high hardness and strength due to its carbon-rich, quenched, and tempered microstructure, making it ideal for applications requiring wear resistance and toughness. Duplex steel combines austenitic and ferritic phases, providing superior corrosion resistance and excellent mechanical properties, especially in harsh environments. Choosing between martensitic and duplex steel depends on the balance needed between strength, toughness, and corrosion resistance in specific industrial applications.

Table of Comparison

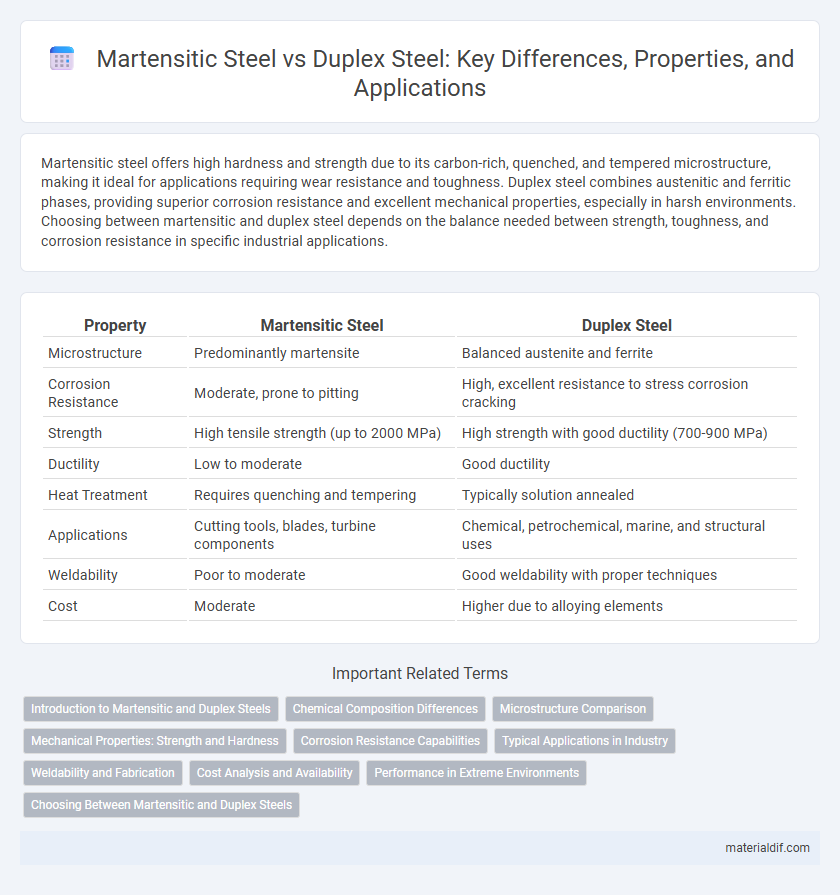

| Property | Martensitic Steel | Duplex Steel |

|---|---|---|

| Microstructure | Predominantly martensite | Balanced austenite and ferrite |

| Corrosion Resistance | Moderate, prone to pitting | High, excellent resistance to stress corrosion cracking |

| Strength | High tensile strength (up to 2000 MPa) | High strength with good ductility (700-900 MPa) |

| Ductility | Low to moderate | Good ductility |

| Heat Treatment | Requires quenching and tempering | Typically solution annealed |

| Applications | Cutting tools, blades, turbine components | Chemical, petrochemical, marine, and structural uses |

| Weldability | Poor to moderate | Good weldability with proper techniques |

| Cost | Moderate | Higher due to alloying elements |

Introduction to Martensitic and Duplex Steels

Martensitic steel is a high-carbon alloy known for its exceptional hardness and strength due to a martensitic microstructure formed by rapid cooling. Duplex steel combines austenitic and ferritic phases, offering superior corrosion resistance and improved toughness. Both steels serve crucial roles in industries requiring a balance of mechanical properties and durability.

Chemical Composition Differences

Martensitic steel typically contains 12-18% chromium with low nickel content, emphasizing high carbon levels around 0.1-1.2% to achieve hardness and wear resistance. Duplex steel combines roughly equal amounts of austenite and ferrite phases, with chromium content ranging from 19-28% and nickel between 4-8%, along with molybdenum additions to enhance corrosion resistance. The higher nickel and balanced phase composition in duplex steels differentiate them chemically from martensitic steels, which are richer in carbon and lower in nickel.

Microstructure Comparison

Martensitic steel features a predominantly martensitic microstructure characterized by needle-like, body-centered tetragonal crystals formed through rapid quenching, resulting in high hardness and strength. Duplex steel exhibits a balanced dual-phase microstructure consisting of approximately equal proportions of austenite and ferrite, providing enhanced toughness and corrosion resistance. The contrasting microstructures directly impact mechanical properties, with martensitic steel excelling in wear resistance, while duplex steel offers superior ductility and stress corrosion cracking resistance.

Mechanical Properties: Strength and Hardness

Martensitic steel exhibits high strength and hardness due to its carbon-rich, quench-hardened microstructure, making it ideal for applications requiring wear resistance and toughness. Duplex steel combines austenitic and ferritic phases, delivering balanced mechanical properties, including high strength and excellent corrosion resistance, but generally lower hardness than martensitic grades. The selection between martensitic and duplex steels depends on the specific strength and hardness requirements alongside corrosion resistance needs.

Corrosion Resistance Capabilities

Martensitic steel exhibits moderate corrosion resistance, primarily suited for environments with low to moderate corrosive exposure due to its high carbon content that can induce sensitization. Duplex steel offers superior corrosion resistance, particularly against stress corrosion cracking and pitting, owing to its balanced austenitic-ferritic microstructure enriched with chromium, molybdenum, and nitrogen. The dual-phase composition of duplex steel ensures enhanced chemical stability and mechanical strength, making it ideal for aggressive chemical and marine applications.

Typical Applications in Industry

Martensitic steel, known for its high hardness and wear resistance, is typically used in applications such as cutting tools, turbine blades, and surgical instruments where strength and durability are critical. Duplex steel, combining austenitic and ferritic properties, is favored in chemical processing, offshore platforms, and desalination plants for its excellent corrosion resistance and toughness. Both steels serve different industrial needs, with martensitic excelling in mechanical performance and duplex providing superior corrosion resistance in harsh environments.

Weldability and Fabrication

Martensitic steel offers moderate weldability but requires precise preheating and post-weld heat treatment to prevent cracking due to its high carbon content and hardness. Duplex steel boasts excellent weldability with reduced susceptibility to hot cracking, thanks to its balanced austenitic and ferritic microstructure, enabling easier fabrication in corrosive environments. Fabrication of duplex steel is generally more cost-effective and efficient compared to martensitic steel, which demands careful thermal management to maintain mechanical properties.

Cost Analysis and Availability

Martensitic steel is generally more affordable due to its simpler alloy composition and widespread production, making it readily available in various grades for industrial applications. Duplex steel, characterized by its balanced microstructure and superior corrosion resistance, typically incurs higher costs driven by complex manufacturing processes and limited raw material availability. Market trends show increasing demand for duplex steel in specialized sectors such as chemical processing, which slightly constrains its supply and elevates pricing compared to the more common martensitic grades.

Performance in Extreme Environments

Martensitic steel offers exceptional hardness and wear resistance, making it ideal for high-temperature and high-stress applications, but its corrosion resistance is relatively limited. Duplex steel combines a balanced microstructure of austenite and ferrite, providing superior resistance to corrosion and stress corrosion cracking, especially in aggressive environments like seawater or chemical processing. The choice between martensitic and duplex steel hinges on balancing the need for strength and hardness against corrosion resistance in extreme conditions.

Choosing Between Martensitic and Duplex Steels

Martensitic steel offers high hardness and strength due to its carbon content and heat treatment, making it ideal for applications requiring wear resistance and toughness, such as cutlery and turbine blades. Duplex steel provides excellent corrosion resistance and superior strength from its balanced austenite and ferrite microstructure, well-suited for chemical processing, marine, and structural uses. Selecting between martensitic and duplex steels depends on balancing required mechanical properties against environmental resistance, with duplex preferred in corrosive environments and martensitic favored where hardness and wear resistance are paramount.

Martensitic Steel vs Duplex Steel Infographic

materialdif.com

materialdif.com