Galvanized steel is coated with a layer of zinc, providing excellent rust protection and durability, making it ideal for outdoor and industrial applications. Aluminized steel features a high-temperature aluminum-silicon alloy coating, offering superior heat resistance and corrosion protection in high-temperature environments like exhaust systems. Choosing between galvanized and aluminized steel depends on the specific requirements for corrosion resistance, heat tolerance, and environmental exposure.

Table of Comparison

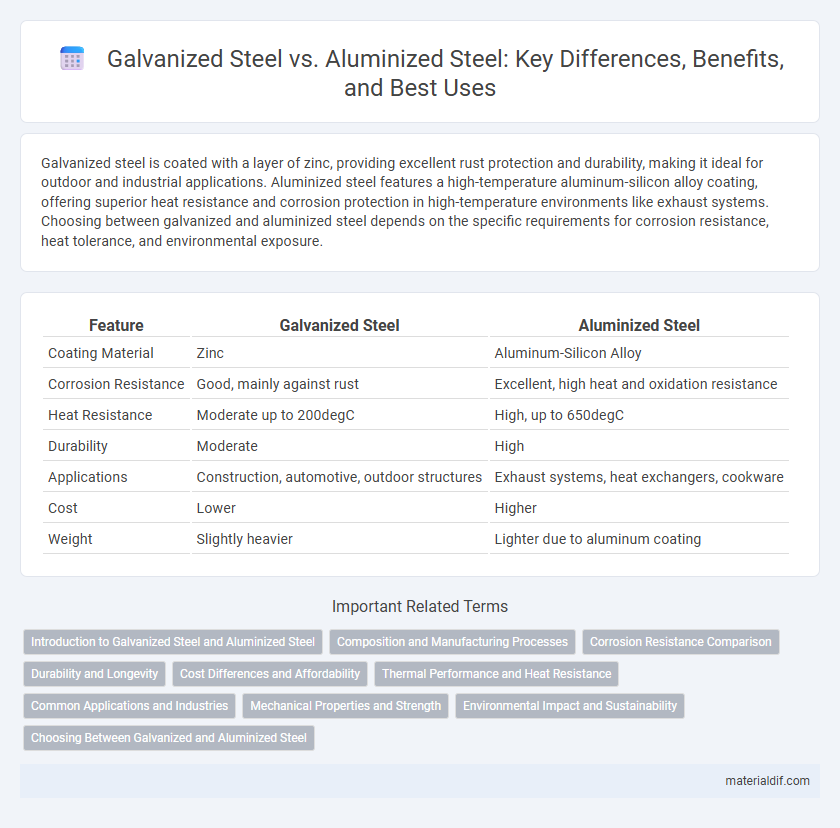

| Feature | Galvanized Steel | Aluminized Steel |

|---|---|---|

| Coating Material | Zinc | Aluminum-Silicon Alloy |

| Corrosion Resistance | Good, mainly against rust | Excellent, high heat and oxidation resistance |

| Heat Resistance | Moderate up to 200degC | High, up to 650degC |

| Durability | Moderate | High |

| Applications | Construction, automotive, outdoor structures | Exhaust systems, heat exchangers, cookware |

| Cost | Lower | Higher |

| Weight | Slightly heavier | Lighter due to aluminum coating |

Introduction to Galvanized Steel and Aluminized Steel

Galvanized steel features a protective zinc coating that prevents corrosion and enhances durability, making it ideal for outdoor and industrial applications. Aluminized steel combines steel with an aluminum-silicon alloy coating, offering superior heat resistance and oxidation protection, commonly used in automotive exhaust systems and furnaces. Both materials extend the lifespan of steel but serve different environments based on their unique protective properties.

Composition and Manufacturing Processes

Galvanized steel features a zinc coating applied through hot-dip or electroplating methods to enhance corrosion resistance, while aluminized steel is coated with an aluminum-silicon alloy via hot-dipping for improved heat reflectivity and oxidation protection. The manufacturing process for galvanized steel involves immersing steel in molten zinc, forming a metallurgical bond, whereas aluminized steel requires immersion in molten aluminum mixed with silicon to create a durable, protective layer. Composition differences impact performance, with galvanized steel prioritizing rust prevention and aluminized steel optimized for high-temperature applications.

Corrosion Resistance Comparison

Galvanized steel features a zinc coating that provides superior corrosion resistance by sacrificially protecting the underlying steel, especially in environments exposed to moisture and salt. Aluminized steel, coated with an aluminum-silicon alloy, excels in high-temperature corrosion resistance and oxidation prevention, making it ideal for automotive exhaust systems and heat exchangers. While galvanized steel offers better protection against general rust and atmospheric corrosion, aluminized steel performs optimally in environments involving elevated temperatures and oxidative conditions.

Durability and Longevity

Galvanized steel features a zinc coating that offers superior corrosion resistance, significantly enhancing its durability in humid or outdoor environments. Aluminized steel, coated with an aluminum-silicon alloy, provides excellent heat resistance and oxidation protection, making it ideal for high-temperature applications. While galvanized steel excels in preventing rust over long periods, aluminized steel typically outlasts it in environments exposed to intense heat and thermal cycling.

Cost Differences and Affordability

Galvanized steel typically costs less than aluminized steel due to the simpler zinc-coating process and widespread availability of materials. Aluminized steel, coated with an aluminum-silicon alloy, offers superior heat and corrosion resistance but comes at a higher price point, impacting overall affordability for large-scale projects. Budget-conscious applications often favor galvanized steel for its cost-effectiveness, while aluminized steel is chosen when durability justifies the increased investment.

Thermal Performance and Heat Resistance

Galvanized steel features a zinc coating that provides moderate heat resistance suitable for applications up to 200degC, making it effective for corrosion protection under standard thermal conditions. Aluminized steel, coated with an aluminum-silicon alloy, offers superior thermal performance with heat resistance typically up to 650degC, ideal for high-temperature environments such as exhaust systems. The aluminum coating also reflects radiant heat, enhancing energy efficiency and extending the steel's lifespan in intense heat applications.

Common Applications and Industries

Galvanized steel is widely used in automotive manufacturing, construction, and agricultural equipment due to its excellent corrosion resistance and durability. Aluminized steel finds common applications in heat exchangers, automotive exhaust systems, and cooking appliances because of its superior heat reflectivity and oxidation resistance. Industries such as automotive, construction, and HVAC frequently select between these materials based on environmental exposure and thermal requirements.

Mechanical Properties and Strength

Galvanized steel exhibits superior corrosion resistance due to its zinc coating, which enhances its durability in harsh environments, while aluminized steel offers excellent heat resistance and maintains mechanical strength at elevated temperatures. The tensile strength of galvanized steel typically ranges from 270 to 550 MPa, making it ideal for structural applications requiring high load-bearing capacity, whereas aluminized steel provides slightly lower tensile strength but better thermal stability. Both materials deliver reliable mechanical performance, but the choice depends on specific environmental exposure and temperature conditions encountered in applications.

Environmental Impact and Sustainability

Galvanized steel involves a zinc coating that offers excellent corrosion resistance but raises environmental concerns due to zinc mining's impact and potential soil contamination during disposal. Aluminized steel, coated with aluminum-silicon alloy, provides superior heat reflectivity and longer lifespan, reducing the frequency of replacement and associated resource consumption. Sustainable steel production increasingly favors aluminized steel for its energy efficiency and lower ecological footprint across the product lifecycle.

Choosing Between Galvanized and Aluminized Steel

Choosing between galvanized steel and aluminized steel depends on the specific environmental exposure and corrosion resistance requirements. Galvanized steel offers superior protection against rust through a zinc coating ideal for outdoor, wet, or humid conditions, while aluminized steel provides enhanced heat resistance and reflective properties, making it suitable for high-temperature applications like automotive exhaust systems and furnaces. Consider factors such as cost, durability, and intended use to select the optimum steel type for construction, manufacturing, or industrial projects.

Galvanized Steel vs Aluminized Steel Infographic

materialdif.com

materialdif.com