Forged steel offers superior strength and durability compared to cast steel due to its refined grain structure and reduced porosity achieved through plastic deformation. Cast steel allows for complex shapes and larger sizes but may exhibit inferior mechanical properties and increased brittleness from the solidification process. Choosing between forged and cast steel depends on the required strength, design complexity, and application-specific performance criteria.

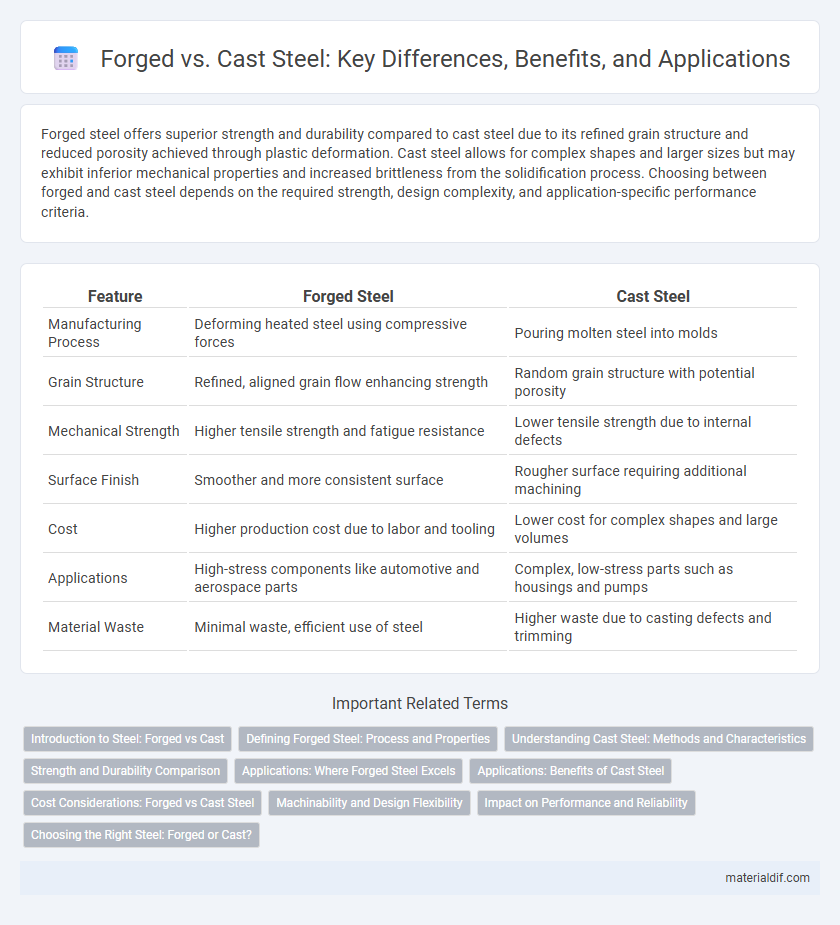

Table of Comparison

| Feature | Forged Steel | Cast Steel |

|---|---|---|

| Manufacturing Process | Deforming heated steel using compressive forces | Pouring molten steel into molds |

| Grain Structure | Refined, aligned grain flow enhancing strength | Random grain structure with potential porosity |

| Mechanical Strength | Higher tensile strength and fatigue resistance | Lower tensile strength due to internal defects |

| Surface Finish | Smoother and more consistent surface | Rougher surface requiring additional machining |

| Cost | Higher production cost due to labor and tooling | Lower cost for complex shapes and large volumes |

| Applications | High-stress components like automotive and aerospace parts | Complex, low-stress parts such as housings and pumps |

| Material Waste | Minimal waste, efficient use of steel | Higher waste due to casting defects and trimming |

Introduction to Steel: Forged vs Cast

Forged steel undergoes high-pressure deformation to refine its grain structure, resulting in enhanced strength and durability compared to cast steel, which is produced by pouring molten metal into molds. The forging process imparts superior mechanical properties, such as improved fatigue resistance and tensile strength, making it ideal for high-performance applications. Cast steel offers greater design flexibility and complex geometries but typically exhibits lower toughness and ductility than forged counterparts.

Defining Forged Steel: Process and Properties

Forged steel is produced by shaping heated metal under high pressure, enhancing its grain structure and mechanical properties. This process results in superior strength, toughness, and resistance to fatigue compared to cast steel. Forged steel components exhibit improved ductility and reliability, making them ideal for critical applications in aerospace, automotive, and heavy machinery industries.

Understanding Cast Steel: Methods and Characteristics

Cast steel is produced by pouring molten steel into molds, allowing for complex shapes and intricate designs with excellent dimensional accuracy. This method offers superior versatility in producing large components and allows for the incorporation of various alloys to enhance mechanical properties such as strength, toughness, and wear resistance. Cast steel typically exhibits a more uniform grain structure compared to other casting methods, resulting in improved durability and performance in heavy-duty applications.

Strength and Durability Comparison

Forged steel exhibits superior strength and durability compared to cast steel due to its refined grain structure and reduced porosity from the forging process. The mechanical properties of forged steel, such as tensile strength and impact resistance, are significantly enhanced, making it ideal for high-stress applications like automotive and aerospace components. Cast steel, while more cost-effective and capable of complex shapes, generally has lower fatigue resistance and may contain internal defects that reduce its overall durability.

Applications: Where Forged Steel Excels

Forged steel is preferred in high-stress applications such as automotive crankshafts, aerospace components, and heavy machinery parts due to its superior strength, fatigue resistance, and structural integrity. Its refined grain structure results from compressive forces during forging, enhancing mechanical properties critical in safety and performance-critical environments. Cast steel, while cost-effective for complex shapes, lacks the toughness and durability required for these demanding uses.

Applications: Benefits of Cast Steel

Cast steel offers superior structural complexity and uniformity, making it ideal for heavy machinery, automotive parts, and pressure vessels that demand high strength and durability. Its ability to create intricate shapes with consistent mechanical properties reduces machining costs and enhances fatigue resistance in critical applications. Industries such as aerospace, oil and gas, and power generation benefit from cast steel's robustness and reliability in harsh operating conditions.

Cost Considerations: Forged vs Cast Steel

Forged steel typically incurs higher initial costs due to its labor-intensive manufacturing process and the need for specialized equipment, but it offers superior strength and durability, reducing long-term maintenance expenses. Cast steel benefits from lower production costs through molding methods, making it cost-effective for complex shapes and large volume runs, though it may require more frequent repairs over time. Evaluating the total lifecycle cost is crucial for choosing between forged and cast steel based on application-specific durability and budget constraints.

Machinability and Design Flexibility

Forged steel offers superior machinability due to its uniform grain structure, resulting in less tool wear and higher precision during machining. Cast steel provides greater design flexibility, allowing complex geometries and intricate shapes that are difficult to achieve through forging. However, the denser microstructure of forged steel enhances mechanical properties, making it preferable for components requiring high strength and durability despite machining challenges.

Impact on Performance and Reliability

Forged steel exhibits superior grain structure alignment, resulting in enhanced strength, toughness, and fatigue resistance compared to cast steel, which often contains internal voids and heterogeneous microstructures. This difference significantly impacts component performance under high stress and cyclical loads, where forged parts demonstrate greater reliability and longer service life. Consequently, critical applications such as aerospace, automotive, and heavy machinery favor forged steel for its consistent structural integrity and durability.

Choosing the Right Steel: Forged or Cast?

Forged steel offers superior strength and durability due to its grain-refined structure, making it ideal for high-stress applications such as automotive and aerospace components. Cast steel provides versatility in complex shapes and sizes, suitable for intricate designs where dimensional accuracy is critical. Selecting forged or cast steel depends on performance requirements, manufacturing complexity, and cost constraints within the intended industrial use.

Forged vs Cast Infographic

materialdif.com

materialdif.com