Boron steel offers exceptional hardness and wear resistance due to its boron content, making it ideal for automotive parts and cutting tools. Manganese steel provides superior impact strength and toughness, excelling in high-stress applications like mining and heavy machinery. Choosing between boron steel and manganese steel depends on the required balance of hardness versus impact resistance for specific industrial uses.

Table of Comparison

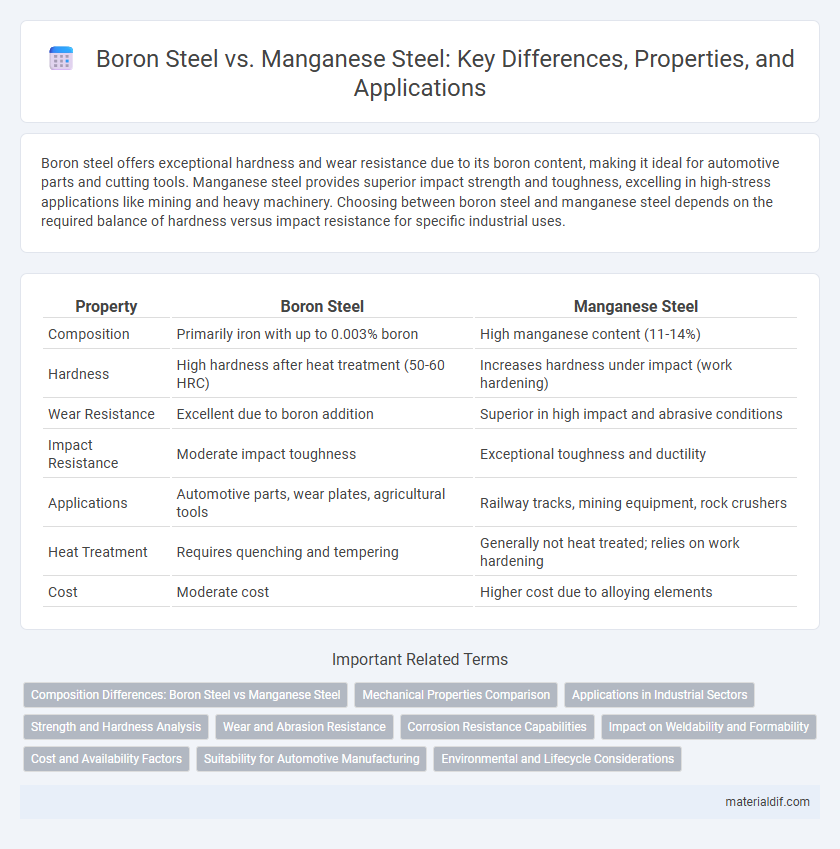

| Property | Boron Steel | Manganese Steel |

|---|---|---|

| Composition | Primarily iron with up to 0.003% boron | High manganese content (11-14%) |

| Hardness | High hardness after heat treatment (50-60 HRC) | Increases hardness under impact (work hardening) |

| Wear Resistance | Excellent due to boron addition | Superior in high impact and abrasive conditions |

| Impact Resistance | Moderate impact toughness | Exceptional toughness and ductility |

| Applications | Automotive parts, wear plates, agricultural tools | Railway tracks, mining equipment, rock crushers |

| Heat Treatment | Requires quenching and tempering | Generally not heat treated; relies on work hardening |

| Cost | Moderate cost | Higher cost due to alloying elements |

Composition Differences: Boron Steel vs Manganese Steel

Boron steel contains a small percentage of boron, typically around 0.001% to 0.003%, which significantly enhances hardness and tensile strength through grain refinement. Manganese steel, on the other hand, includes manganese content ranging from 11% to 14%, contributing to its exceptional toughness and resistance to abrasion and impact. The differing compositions result in boron steel being ideal for wear-resistant applications requiring high strength, while manganese steel excels in environments subject to heavy impact and deformation.

Mechanical Properties Comparison

Boron steel exhibits higher tensile strength and hardness due to its alloying element boron, which enhances wear resistance and hardenability. Manganese steel, known for its exceptional toughness and impact resistance, offers superior ductility and work-hardening capabilities under high-stress conditions. The mechanical properties of boron steel make it suitable for cutting tools and wear parts, while manganese steel excels in applications requiring high abrasion resistance and shock absorption.

Applications in Industrial Sectors

Boron steel is extensively used in the automotive industry for manufacturing high-strength safety components and in construction for wear-resistant tools, benefiting from its hardness and abrasion resistance. Manganese steel finds significant application in mining and heavy machinery sectors due to its exceptional impact resistance and ability to endure extreme abrasion, making it ideal for crushers, excavators, and railway track work. Both steels serve critical roles in industrial sectors requiring durability and toughness under harsh operating conditions.

Strength and Hardness Analysis

Boron steel exhibits superior hardness due to boron's ability to enhance hardenability and tensile strength, making it ideal for wear-resistant applications. Manganese steel offers exceptional toughness and impact strength, providing high resistance to abrasion and deformation under heavy loads. The choice between boron and manganese steel depends on the balance required between hardness and ductility for specific industrial uses.

Wear and Abrasion Resistance

Boron steel offers superior wear resistance due to its ability to harden significantly through heat treatment, making it ideal for applications requiring high abrasion resistance. Manganese steel, characterized by its exceptional work hardening properties, excels in environments with high impact and cutting forces but may be less effective against abrasive wear compared to boron steel. The selection between boron steel and manganese steel should consider the specific wear conditions, with boron steel favored for abrasive wear and manganese steel preferred for high-impact resistance.

Corrosion Resistance Capabilities

Boron steel exhibits superior corrosion resistance due to the presence of boron, which enhances hardenability and forms stable oxides that protect against rust and environmental degradation. In contrast, manganese steel offers moderate corrosion resistance but excels in impact toughness and abrasion resistance rather than protection against oxidation. For applications requiring robust resistance to chemical wear and moisture, boron steel outperforms manganese steel in maintaining structural integrity over time.

Impact on Weldability and Formability

Boron steel offers enhanced weldability due to its low carbon content combined with boron's ability to increase hardness without compromising the welding process, making it suitable for complex fabrications. Manganese steel, known for its high impact strength and work-hardening properties, presents challenges in weldability because of its tendency to crack and distort under heat, requiring specialized welding techniques. Formability in boron steel is superior for precision components, whereas manganese steel's exceptional toughness limits its formability but excels in high-impact applications.

Cost and Availability Factors

Boron steel generally offers lower cost and higher availability compared to manganese steel due to its widespread production and simpler alloying process. Manganese steel, while providing superior toughness and wear resistance, tends to be more expensive and less readily available because of its complex manufacturing requirements and specialized demand. Cost efficiency and supply chain considerations often make boron steel the preferred choice for large-scale, cost-sensitive projects.

Suitability for Automotive Manufacturing

Boron steel offers exceptional hardness and tensile strength, making it highly suitable for automotive manufacturing components that require wear resistance and impact durability, such as chassis and safety parts. Manganese steel provides superior toughness and resistance to abrasion, ideal for parts subjected to high impact and strain, like gears and suspension systems. The choice between boron steel and manganese steel depends on specific performance needs, with boron steel favored for structural integrity and manganese steel preferred for components facing intense mechanical stress.

Environmental and Lifecycle Considerations

Boron steel offers enhanced hardenability and wear resistance, resulting in longer lifespan and reduced material waste, which lowers its environmental footprint compared to manganese steel. Manganese steel, known for its high toughness and impact resistance, requires more energy-intensive processing and frequent replacements, increasing lifecycle emissions. Sustainable steel production increasingly favors boron steel for applications prioritizing durability and reduced ecological impact throughout the product lifecycle.

Boron Steel vs Manganese Steel Infographic

materialdif.com

materialdif.com