High-carbon steel contains approximately 0.6% to 1.0% carbon, making it harder and more wear-resistant but less ductile compared to low-carbon steel, which has less than 0.3% carbon. Low-carbon steel offers greater malleability and weldability, making it ideal for structural applications where flexibility is essential. The choice between high-carbon and low-carbon steel depends on the required balance between strength, hardness, and formability for specific industrial uses.

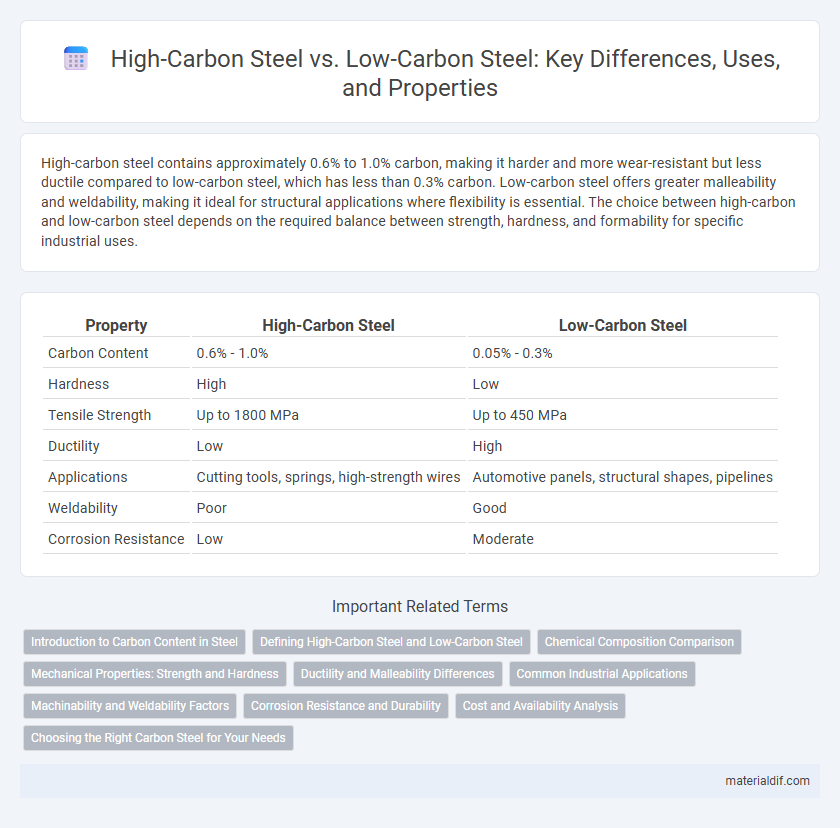

Table of Comparison

| Property | High-Carbon Steel | Low-Carbon Steel |

|---|---|---|

| Carbon Content | 0.6% - 1.0% | 0.05% - 0.3% |

| Hardness | High | Low |

| Tensile Strength | Up to 1800 MPa | Up to 450 MPa |

| Ductility | Low | High |

| Applications | Cutting tools, springs, high-strength wires | Automotive panels, structural shapes, pipelines |

| Weldability | Poor | Good |

| Corrosion Resistance | Low | Moderate |

Introduction to Carbon Content in Steel

High-carbon steel contains approximately 0.6% to 1.0% carbon, which significantly increases hardness and tensile strength compared to low-carbon steel, which typically has less than 0.3% carbon. The carbon content directly influences the steel's properties, with high-carbon steel offering greater wear resistance but reduced ductility, while low-carbon steel provides enhanced flexibility and weldability. Understanding carbon percentages is essential for selecting the appropriate steel type for specific applications in construction, manufacturing, and tool making.

Defining High-Carbon Steel and Low-Carbon Steel

High-carbon steel contains approximately 0.6% to 1.4% carbon, offering increased hardness and strength but reduced ductility compared to low-carbon steel. Low-carbon steel, typically containing less than 0.3% carbon, provides greater malleability and is easier to weld and form, making it ideal for structural applications. The carbon content directly affects mechanical properties, influencing the material's suitability for tools, automotive parts, and construction.

Chemical Composition Comparison

High-carbon steel typically contains 0.6% to 1.0% carbon, resulting in increased hardness and tensile strength compared to low-carbon steel, which has a carbon content of 0.05% to 0.3%. The higher carbon content in high-carbon steel also reduces its ductility and weldability, whereas low-carbon steel maintains better malleability and ease of fabrication due to its lower carbon percentage. Trace elements such as manganese (around 0.3% to 0.9%) assist in hardenability for both types, but high-carbon steel often includes slightly higher manganese levels to improve strength and wear resistance.

Mechanical Properties: Strength and Hardness

High-carbon steel contains approximately 0.6% to 1.0% carbon, resulting in superior tensile strength and hardness compared to low-carbon steel, which typically has 0.05% to 0.3% carbon content. The increased carbon content enhances heat treatability, allowing high-carbon steel to achieve hardness levels above 60 HRC, making it ideal for cutting tools and wear-resistant applications. Low-carbon steel exhibits lower strength and hardness but offers greater ductility and toughness, which suits structural components requiring impact resistance.

Ductility and Malleability Differences

High-carbon steel contains approximately 0.6% to 1.0% carbon, resulting in lower ductility and malleability but higher hardness and strength, making it ideal for cutting tools and wear-resistant applications. Low-carbon steel, with less than 0.3% carbon content, exhibits greater ductility and malleability, allowing it to be easily formed and welded for structural components and automotive parts. The varying carbon levels directly influence the microstructure, with high-carbon steel having more pearlite and cementite, reducing flexibility, while low-carbon steel maintains a softer ferrite phase.

Common Industrial Applications

High-carbon steel, containing approximately 0.6% to 1.0% carbon, is commonly used in cutting tools, springs, and high-strength wires due to its increased hardness and wear resistance. Low-carbon steel, with less than 0.3% carbon content, is widely applied in construction, automotive manufacturing, and structural components for its excellent ductility and weldability. Both types serve distinct industrial purposes, driven by their differing mechanical properties tailored to specific performance requirements.

Machinability and Weldability Factors

High-carbon steel exhibits lower machinability due to its hardness and wear resistance, which challenges cutting tool life and precision. In contrast, low-carbon steel offers superior machinability, enabling easier shaping and forming during manufacturing processes. Weldability is significantly better in low-carbon steel because of its reduced carbon content, minimizing the risk of cracking and ensuring stronger, more reliable weld joints.

Corrosion Resistance and Durability

High-carbon steel offers superior hardness and wear resistance but tends to have lower corrosion resistance due to its higher carbon content, making it more susceptible to rust without proper protective coatings. Low-carbon steel, with its reduced carbon levels, provides better ductility and enhanced corrosion resistance, especially when alloyed with elements like chromium or coated with protective layers. The durability of low-carbon steel in corrosive environments outperforms high-carbon steel, which is better suited for applications requiring strength and abrasion resistance rather than prolonged exposure to moisture or corrosive elements.

Cost and Availability Analysis

High-carbon steel typically costs more than low-carbon steel due to its enhanced strength and durability, which require more intensive processing and alloying elements. Low-carbon steel is more widely available and economical for large-scale manufacturing, making it the preferred choice for construction and automotive industries. Market demand and production scalability heavily influence the pricing and accessibility of these two steel types.

Choosing the Right Carbon Steel for Your Needs

High-carbon steel contains approximately 0.6% to 1.0% carbon, providing superior hardness and strength ideal for cutting tools and springs, while low-carbon steel, with less than 0.3% carbon, offers better ductility and weldability suited for structural applications and automotive parts. Selecting the right carbon steel depends on the required mechanical properties, such as tensile strength, wear resistance, and formability. Understanding the balance between carbon content and desired performance ensures optimal material choice for manufacturing or construction projects.

High-Carbon Steel vs Low-Carbon Steel Infographic

materialdif.com

materialdif.com