Weathering steel offers superior corrosion resistance compared to conventional steel, forming a stable rust-like appearance that protects the underlying metal from further deterioration. This patina eliminates the need for painting or additional coatings, reducing maintenance costs and extending the lifespan of structures. Conventional steel requires regular maintenance and protective coatings to prevent rust and damage over time, making weathering steel a cost-effective and durable alternative in outdoor applications.

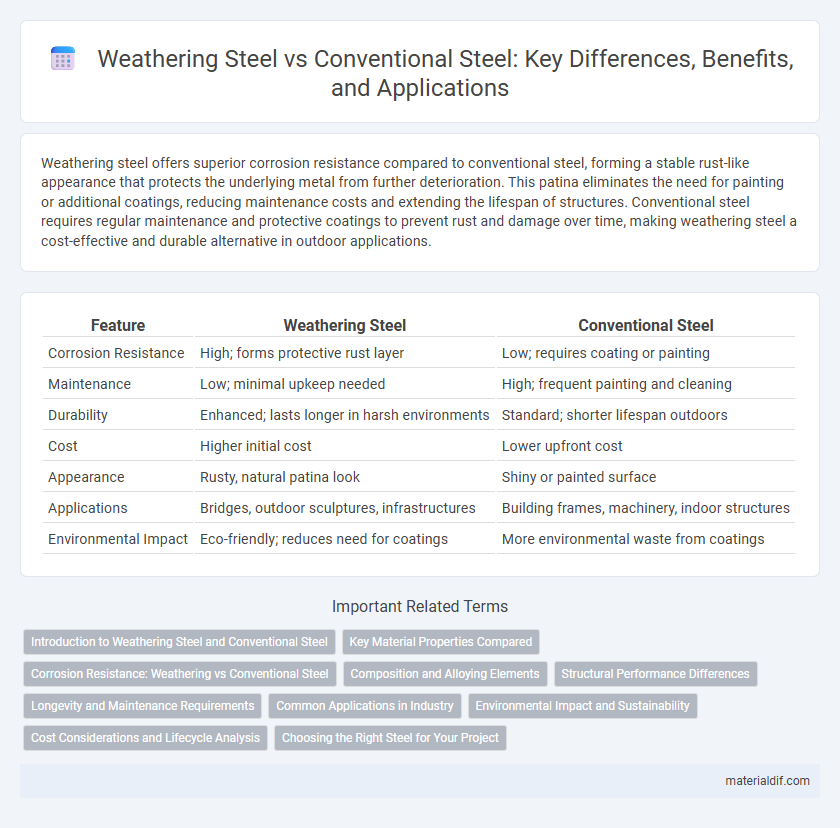

Table of Comparison

| Feature | Weathering Steel | Conventional Steel |

|---|---|---|

| Corrosion Resistance | High; forms protective rust layer | Low; requires coating or painting |

| Maintenance | Low; minimal upkeep needed | High; frequent painting and cleaning |

| Durability | Enhanced; lasts longer in harsh environments | Standard; shorter lifespan outdoors |

| Cost | Higher initial cost | Lower upfront cost |

| Appearance | Rusty, natural patina look | Shiny or painted surface |

| Applications | Bridges, outdoor sculptures, infrastructures | Building frames, machinery, indoor structures |

| Environmental Impact | Eco-friendly; reduces need for coatings | More environmental waste from coatings |

Introduction to Weathering Steel and Conventional Steel

Weathering steel, also known as COR-TEN steel, is designed to develop a stable, rust-like appearance after exposure to weather, forming a protective layer that reduces corrosion and maintenance needs. Conventional steel typically requires protective coatings such as paint or galvanization to prevent rust and degradation over time in outdoor environments. The unique alloy composition of weathering steel, including elements like copper, chromium, and nickel, enhances its resistance to atmospheric corrosion compared to conventional carbon steel.

Key Material Properties Compared

Weathering steel exhibits superior corrosion resistance compared to conventional steel due to its alloying elements like copper, chromium, and nickel, which form a protective oxide layer, reducing maintenance costs and extending service life. Conventional steel, while generally stronger in tensile strength and more ductile, requires protective coatings to prevent rust and degradation in outdoor environments. The distinct weathering steel properties enable its use in infrastructure exposed to harsh weather, whereas conventional steel is preferred for applications prioritizing strength and weldability.

Corrosion Resistance: Weathering vs Conventional Steel

Weathering steel contains alloying elements like copper, chromium, and nickel, which form a stable, protective oxide layer that significantly enhances its corrosion resistance compared to conventional steel. Conventional steel lacks this protective layer, making it more susceptible to rust and requiring frequent maintenance or coatings to prevent corrosion. The inherent durability of weathering steel reduces lifecycle costs and improves performance in outdoor environments exposed to varying weather conditions.

Composition and Alloying Elements

Weathering steel contains higher amounts of copper, chromium, and nickel compared to conventional steel, enhancing its corrosion resistance through the formation of a stable oxide layer. Conventional steel primarily consists of iron and carbon with minimal alloying elements, making it more prone to rust without protective coatings. The specific alloying elements in weathering steel promote self-healing rust layers, significantly extending its service life in outdoor environments.

Structural Performance Differences

Weathering steel exhibits superior corrosion resistance compared to conventional steel, significantly enhancing its structural durability in outdoor environments. The protective oxide layer formed on weathering steel reduces maintenance needs and extends lifespan without sacrificing strength or load-bearing capacity. Conventional steel, while strong, typically requires protective coatings to prevent rust and degradation, potentially increasing lifecycle costs and reducing long-term structural performance.

Longevity and Maintenance Requirements

Weathering steel offers superior longevity compared to conventional steel due to its corrosion-resistant alloy composition, which forms a protective oxide layer that inhibits rust progression. Conventional steel requires frequent maintenance such as painting or coating to prevent corrosion and extend its lifespan. The reduced need for maintenance in weathering steel results in lower life-cycle costs and enhanced durability in outdoor and harsh environmental applications.

Common Applications in Industry

Weathering steel is commonly used in bridge construction, outdoor sculptures, and building facades due to its corrosion resistance and minimal maintenance requirements. Conventional steel finds widespread application in automotive manufacturing, machinery, and structural frameworks where cost-effectiveness and ease of fabrication are prioritized. Both steel types serve critical roles across infrastructure, transportation, and heavy industry sectors depending on environmental exposure and durability needs.

Environmental Impact and Sustainability

Weathering steel significantly reduces environmental impact by forming a protective oxide layer that eliminates the need for painting and extensive maintenance, thus lowering lifecycle emissions and resource consumption. Conventional steel requires frequent coatings and upkeep, increasing the demand for volatile organic compounds (VOCs) and energy-intensive maintenance processes, which contribute to higher carbon footprints. The sustainability of weathering steel is enhanced through its durability and ability to withstand harsh weather conditions, promoting longer service life and reducing waste in construction and infrastructure projects.

Cost Considerations and Lifecycle Analysis

Weathering steel offers lower lifecycle costs compared to conventional steel by minimizing maintenance expenses through its corrosion-resistant properties that eliminate the need for painting or frequent repairs. Initial material costs for weathering steel may be higher, but reduced expenditures on surface treatments and longer service life provide overall economic benefits. Lifecycle analysis highlights weathering steel's sustainability advantages, including decreased resource consumption and lower environmental impact throughout the steel structure's operational duration.

Choosing the Right Steel for Your Project

Weathering steel offers superior corrosion resistance by forming a protective oxide layer, reducing maintenance costs for outdoor structures compared to conventional steel. Conventional steel provides higher initial strength and is more cost-effective for applications requiring frequent painting or indoor use where corrosion is less critical. Selecting the right steel depends on project needs, environmental exposure, lifecycle costs, and structural performance requirements.

Weathering steel vs Conventional steel Infographic

materialdif.com

materialdif.com