Dual phase steel offers a balanced combination of high strength and ductility due to its microstructure of soft ferrite and hard martensite phases, making it ideal for automotive applications. Martensitic steel, characterized by its predominantly martensitic structure, provides superior hardness and wear resistance, suitable for tools and high-strength components. While dual phase steel excels in formability and energy absorption during crashes, martensitic steel is preferred where maximum strength and toughness are critical.

Table of Comparison

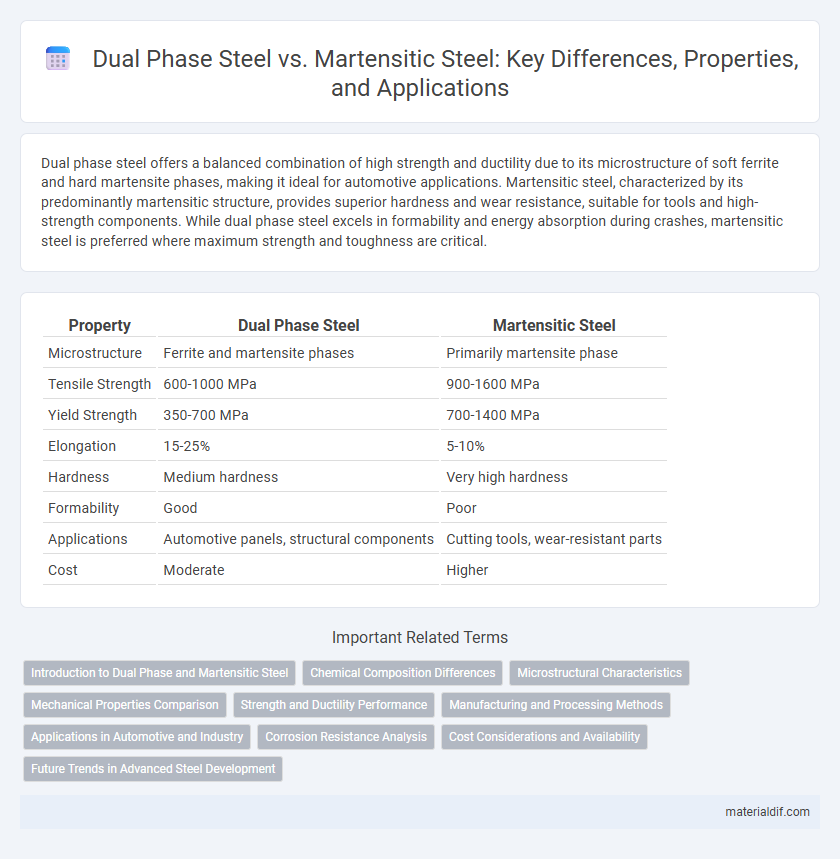

| Property | Dual Phase Steel | Martensitic Steel |

|---|---|---|

| Microstructure | Ferrite and martensite phases | Primarily martensite phase |

| Tensile Strength | 600-1000 MPa | 900-1600 MPa |

| Yield Strength | 350-700 MPa | 700-1400 MPa |

| Elongation | 15-25% | 5-10% |

| Hardness | Medium hardness | Very high hardness |

| Formability | Good | Poor |

| Applications | Automotive panels, structural components | Cutting tools, wear-resistant parts |

| Cost | Moderate | Higher |

Introduction to Dual Phase and Martensitic Steel

Dual Phase steel features a microstructure combining soft ferrite and hard martensite, offering a balance of high strength and ductility ideal for automotive applications. Martensitic steel, characterized by a predominantly martensitic microstructure, provides exceptional tensile strength and hardness, making it suitable for wear-resistant components. Both steels are integral in modern manufacturing due to their unique mechanical properties tailored for specific engineering demands.

Chemical Composition Differences

Dual Phase Steel typically contains a higher percentage of manganese (1.2-2.0%) and lower carbon content (0.06-0.12%), promoting a microstructure of ferrite and martensite for enhanced ductility and strength. Martensitic Steel has increased carbon content (0.10-1.2%) with lower manganese levels, resulting in a predominantly martensitic microstructure that provides superior hardness and tensile strength. The variation in silicon and other alloying elements also influences phase transformation kinetics and mechanical properties between the two steel types.

Microstructural Characteristics

Dual phase steel exhibits a microstructure composed of ferrite and martensite phases, offering a balanced combination of ductility and strength due to the soft ferrite matrix reinforced by hard martensite islands. In contrast, martensitic steel primarily consists of a fully martensitic microstructure, characterized by a highly distorted body-centered tetragonal lattice, which provides superior hardness and tensile strength but reduced ductility. The volume fraction, distribution, and morphology of martensite critically influence mechanical behavior, with dual phase steels showing better strain hardening and formability compared to the brittle nature of martensitic steels.

Mechanical Properties Comparison

Dual phase steel offers a balanced combination of high tensile strength and excellent ductility, typically featuring tensile strengths between 600-1000 MPa with elongation values up to 20%. Martensitic steel, by contrast, exhibits superior hardness and tensile strength ranging from 1000 to 1600 MPa but with significantly lower ductility, usually below 10% elongation. The mechanical properties make dual phase steel ideal for applications requiring energy absorption and formability, whereas martensitic steel suits high-strength, wear-resistant components.

Strength and Ductility Performance

Dual phase steel exhibits a balanced combination of high strength and excellent ductility due to its microstructure comprising a soft ferrite matrix with hard martensite islands. Martensitic steel, known for superior strength and hardness, often sacrifices ductility, leading to lower formability under tensile stress. The enhanced ductility of dual phase steel makes it preferable for automotive applications requiring energy absorption without compromising structural integrity.

Manufacturing and Processing Methods

Dual phase steel is produced through a controlled heat treatment process involving intercritical annealing and rapid cooling, resulting in a microstructure with soft ferrite and hard martensite phases for enhanced strength and ductility. Martensitic steel undergoes quenching from the austenitizing temperature followed by tempering, which refines the microstructure to achieve very high hardness and tensile strength but with reduced formability. Manufacturing dual phase steel typically involves precise temperature control during hot rolling, whereas martensitic steel requires rapid cooling techniques and subsequent tempering to optimize mechanical properties.

Applications in Automotive and Industry

Dual Phase Steel offers excellent formability and high strength, making it ideal for automotive body panels and structural components where crash resistance and weight reduction are critical. Martensitic Steel provides superior hardness and tensile strength, commonly used in automotive safety parts such as seat frames and door beams, as well as industrial tooling and machinery requiring high wear resistance. Both steels contribute to enhanced vehicle performance and durability in diverse industrial applications.

Corrosion Resistance Analysis

Dual Phase Steel exhibits improved corrosion resistance due to its balanced microstructure of ferrite and martensite, which provides a protective oxide layer that reduces susceptibility to environmental degradation. In contrast, Martensitic Steel, with its high carbon content and fully martensitic structure, tends to have lower corrosion resistance, often requiring additional surface treatments or coatings to prevent rust and oxidation. Studies show that Dual Phase Steel's heterogeneous microstructure offers better performance in corrosive environments, making it favorable for automotive applications demanding both strength and durability.

Cost Considerations and Availability

Dual phase steel offers a cost advantage over martensitic steel due to its lower alloying element content and simpler heat treatment process, making it more economical for large-scale production. Martensitic steel, with higher carbon content and complex quenching techniques, incurs increased manufacturing costs but provides superior strength and hardness. Availability-wise, dual phase steel is more widely accessible in automotive and structural applications, whereas martensitic steel is limited to specialized uses due to its higher processing demands.

Future Trends in Advanced Steel Development

Dual phase steel, characterized by a microstructure of ferrite and martensite, offers a compelling balance of strength and ductility, appealing to automotive manufacturers striving for lightweight yet durable components. Martensitic steel, known for its high hardness and tensile strength due to a fully martensitic microstructure, remains crucial for applications demanding extreme strength and wear resistance. Future trends in advanced steel development focus on enhancing these steels through alloying innovations, thermomechanical processing, and nanostructuring techniques to achieve superior performance in fuel efficiency, safety, and sustainability.

Dual Phase Steel vs Martensitic Steel Infographic

materialdif.com

materialdif.com