Steel coils offer enhanced flexibility and ease of transportation, making them ideal for large-scale industrial applications requiring continuous processing. Steel bars provide superior strength and rigidity, commonly used in construction and structural frameworks for their load-bearing capabilities. Selecting between steel coil and steel bar depends on project requirements such as shape, durability, and specific mechanical properties.

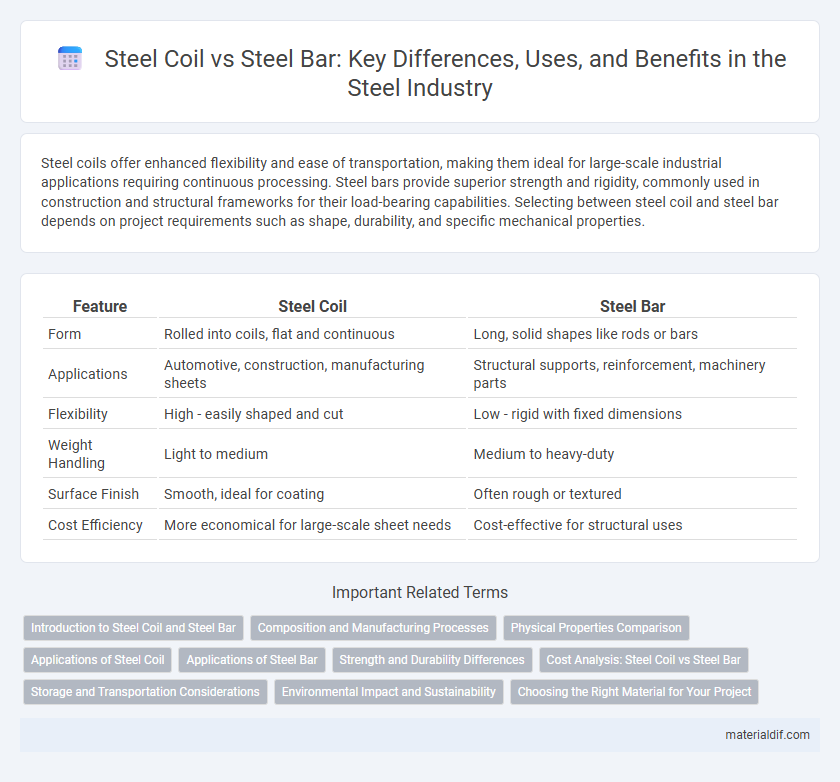

Table of Comparison

| Feature | Steel Coil | Steel Bar |

|---|---|---|

| Form | Rolled into coils, flat and continuous | Long, solid shapes like rods or bars |

| Applications | Automotive, construction, manufacturing sheets | Structural supports, reinforcement, machinery parts |

| Flexibility | High - easily shaped and cut | Low - rigid with fixed dimensions |

| Weight Handling | Light to medium | Medium to heavy-duty |

| Surface Finish | Smooth, ideal for coating | Often rough or textured |

| Cost Efficiency | More economical for large-scale sheet needs | Cost-effective for structural uses |

Introduction to Steel Coil and Steel Bar

Steel coils are continuous rolls of steel sheets or strips used primarily in manufacturing processes requiring flat or curved parts, offering high flexibility and uniform thickness. Steel bars, solid cylindrical or rectangular cross-sectional products, are commonly employed in construction and machinery for their strength and rigidity. Both steel coil and steel bar serve distinct industrial needs based on form, application, and mechanical properties.

Composition and Manufacturing Processes

Steel coils are produced by rolling steel slabs or strips into a continuous coil, typically composed of low to medium carbon steel, enabling flexibility and ease of transport. Steel bars, often made with higher carbon content or alloying elements, undergo processes like hot rolling or forging to enhance strength and durability for construction and machining applications. The manufacturing process of coils emphasizes thin sheet formation, while bars focus on achieving solid, uniform cross-sections with high tensile properties.

Physical Properties Comparison

Steel coils exhibit greater flexibility and improved tensile strength due to their rolled form, making them ideal for applications requiring bending and shaping. In contrast, steel bars provide higher rigidity and compressive strength, essential for structural support and load-bearing uses. The density and thermal conductivity of both remain similar, but their mechanical behavior diverges significantly based on their shape and processing methods.

Applications of Steel Coil

Steel coils are extensively used in automotive manufacturing for producing car bodies, chassis, and exhaust systems due to their flexibility and uniform thickness. In construction, steel coils serve in roofing, wall panels, and structural framing, providing durability and corrosion resistance. Their versatility extends to appliance fabrication and metal packaging, where consistent quality and easy processing are essential.

Applications of Steel Bar

Steel bars are primarily used in construction for reinforcing concrete structures, providing tensile strength to buildings, bridges, and highways. Their adaptability allows them to be shaped into various diameters and lengths, making them ideal for structural frameworks, infrastructure projects, and manufacturing heavy machinery. Unlike steel coils, steel bars are essential for load-bearing applications requiring durability and resistance to bending.

Strength and Durability Differences

Steel coils exhibit superior strength due to their continuous, uniform grain structure formed during the rolling process, enhancing tensile strength and resistance to deformation. Steel bars, while robust, often have varied microstructures leading to slightly lower durability under dynamic stresses compared to steel coils. The superior tensile strength and fatigue resistance of steel coils make them ideal for applications requiring high durability and consistent performance.

Cost Analysis: Steel Coil vs Steel Bar

Steel coils generally offer lower material costs compared to steel bars due to their efficient manufacturing process and reduced transportation expenses. The cost per ton for steel coils is often more competitive, benefiting bulk buyers in industries like construction and automotive. However, steel bars may incur higher handling and processing costs, affecting overall project budgets depending on application requirements.

Storage and Transportation Considerations

Steel coils require specialized storage racks and flat surfaces to prevent deformation and corrosion, often necessitating climate-controlled environments to maintain material integrity. In contrast, steel bars can be stacked with less stringent spatial requirements but demand secure bundling to avoid displacement during transport. Transportation of steel coils involves heavy-duty lifting equipment and flatbed trucks designed to cradle the coil's curvature, while steel bars are typically handled using cranes or forklifts and transported on open trailers with protective strapping.

Environmental Impact and Sustainability

Steel coils have a lower environmental impact compared to steel bars due to their more efficient production process, which consumes less energy and generates fewer carbon emissions. Steel coils enable greater material optimization and waste reduction during manufacturing, contributing to enhanced sustainability in construction projects. Recycling steel coils also requires less energy than processing steel bars, further minimizing their ecological footprint.

Choosing the Right Material for Your Project

Steel coils offer flexibility and efficiency for large-scale manufacturing and fabrication projects, providing consistent thickness and easy transportation. Steel bars are ideal for structural applications requiring high strength and durability, especially in construction and reinforcement tasks. Selecting the right material depends on project specifications such as load requirements, fabrication processes, and end-use conditions.

Steel Coil vs Steel Bar Infographic

materialdif.com

materialdif.com