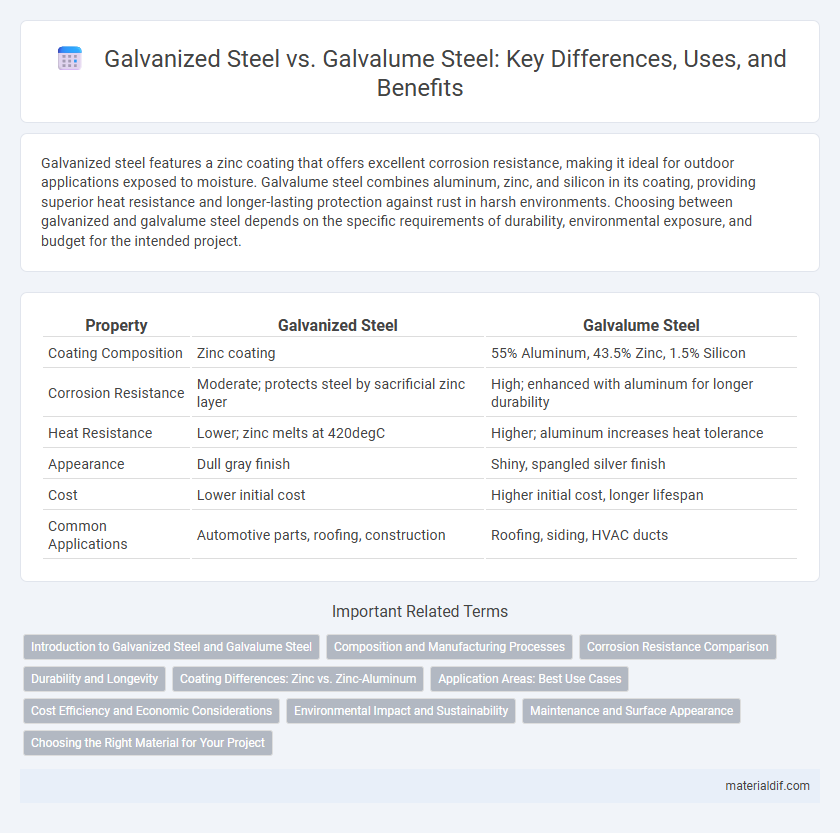

Galvanized steel features a zinc coating that offers excellent corrosion resistance, making it ideal for outdoor applications exposed to moisture. Galvalume steel combines aluminum, zinc, and silicon in its coating, providing superior heat resistance and longer-lasting protection against rust in harsh environments. Choosing between galvanized and galvalume steel depends on the specific requirements of durability, environmental exposure, and budget for the intended project.

Table of Comparison

| Property | Galvanized Steel | Galvalume Steel |

|---|---|---|

| Coating Composition | Zinc coating | 55% Aluminum, 43.5% Zinc, 1.5% Silicon |

| Corrosion Resistance | Moderate; protects steel by sacrificial zinc layer | High; enhanced with aluminum for longer durability |

| Heat Resistance | Lower; zinc melts at 420degC | Higher; aluminum increases heat tolerance |

| Appearance | Dull gray finish | Shiny, spangled silver finish |

| Cost | Lower initial cost | Higher initial cost, longer lifespan |

| Common Applications | Automotive parts, roofing, construction | Roofing, siding, HVAC ducts |

Introduction to Galvanized Steel and Galvalume Steel

Galvanized steel features a protective zinc coating that enhances corrosion resistance, commonly used in construction and automotive industries for its durability. Galvalume steel combines aluminum, zinc, and silicon coatings, providing superior rust protection and heat resistance compared to traditional galvanized steel. Both materials offer distinct advantages in longevity and environmental resistance, influencing their application based on specific project requirements.

Composition and Manufacturing Processes

Galvanized steel features a zinc coating applied through a hot-dip process, providing excellent corrosion resistance by forming a protective barrier on the steel surface. Galvalume steel combines a zinc-aluminum alloy coating, typically about 55% aluminum and 43.5% zinc, applied via continuous hot-dipping, enhancing heat resistance and longevity compared to conventional galvanized steel. The manufacturing of Galvalume involves precise alloying and controlled cooling to achieve superior adherence and durability, whereas galvanized steel production primarily focuses on zinc purity and coating thickness.

Corrosion Resistance Comparison

Galvalume steel offers superior corrosion resistance compared to galvanized steel due to its aluminum-zinc alloy coating, which provides enhanced protection against rust and environmental factors. The aluminum in Galvalume forms a stable oxide layer that shields the steel, resulting in longer service life, especially in harsh or coastal environments. Galvanized steel, coated primarily with zinc, corrodes faster under prolonged exposure to moisture and acidic conditions, making Galvalume a preferred choice for durability and maintenance reduction.

Durability and Longevity

Galvanized steel features a zinc coating that provides strong corrosion resistance, making it durable for outdoor applications. Galvalume steel combines zinc with aluminum in its coating, offering superior longevity due to enhanced protection against rust and heat. The aluminum content in Galvalume significantly extends the lifespan compared to traditional galvanized steel, especially in harsh environments.

Coating Differences: Zinc vs. Zinc-Aluminum

Galvanized steel features a coating of pure zinc that provides sacrificial protection against corrosion by oxidizing before the steel substrate. Galvalume steel utilizes a zinc-aluminum alloy coating, typically comprising about 55% aluminum and 45% zinc, which offers enhanced resistance to heat and rust by forming a stable, protective barrier. The zinc-aluminum coating in Galvalume reduces corrosion rates, especially in high-temperature or marine environments, making it superior to the pure zinc coating of galvanized steel for long-term durability.

Application Areas: Best Use Cases

Galvanized steel, coated with a layer of zinc, excels in applications requiring corrosion resistance in outdoor structures such as fencing, roofing, and automotive parts due to its durability against rust. Galvalume steel, combining aluminum, zinc, and silicon coatings, offers superior heat resistance and longevity, making it ideal for roofing, wall panels, and HVAC systems exposed to harsh weather and high temperatures. Both materials are widely used in construction and manufacturing, but Galvalume's enhanced protection suits environments with intense exposure to moisture and heat.

Cost Efficiency and Economic Considerations

Galvanized steel typically costs less upfront due to its zinc coating, making it a budget-friendly option for projects with shorter lifespans or minimal exposure to corrosive environments. Galvalume steel, coated with an aluminum-zinc alloy, offers superior corrosion resistance and longevity, leading to lower maintenance and replacement costs over time despite a higher initial investment. Choosing between galvanized and galvalume steel hinges on balancing immediate budget constraints against long-term economic benefits and durability requirements.

Environmental Impact and Sustainability

Galvalume steel offers superior corrosion resistance due to its aluminum-zinc coating, which extends the lifespan of structures and reduces the frequency of replacements, lowering overall environmental impact. Both galvanized and Galvalume steel are recyclable, but Galvalume's enhanced durability contributes to resource conservation and less landfill waste over time. Lifecycle assessments show Galvalume steel's improved energy efficiency in production and maintenance phases supports greater sustainability compared to traditional galvanized steel.

Maintenance and Surface Appearance

Galvanized steel features a zinc coating that provides excellent corrosion resistance but may develop white rust over time, requiring periodic maintenance to preserve its surface integrity. Galvalume steel, coated with a combination of zinc and aluminum, offers superior resistance to rust and maintains a smoother, shinier appearance with minimal upkeep. The aluminum content in Galvalume enhances durability, reducing paint maintenance and prolonging the lifespan of the surface finish compared to traditional galvanized steel.

Choosing the Right Material for Your Project

Galvanized steel offers superior corrosion resistance due to its zinc coating, making it ideal for projects exposed to harsh outdoor environments or high moisture. Galvalume steel combines aluminum and zinc coatings, providing enhanced heat reflectivity and longer lifespan in applications such as roofing and siding where durability and aesthetic appeal are essential. Selecting between galvanized and Galvalume steel depends on factors like environmental exposure, budget constraints, and the specific structural demands of your project.

Galvanized Steel vs Galvalume Steel Infographic

materialdif.com

materialdif.com