Sheet steel is thinner and more flexible, making it ideal for applications requiring bending or forming, such as automotive panels and appliances. Plate steel is thicker and stronger, suited for structural uses where durability and load-bearing capacity are critical, including bridges and heavy machinery. Choosing between sheet and plate steel depends on the specific strength, thickness, and application requirements.

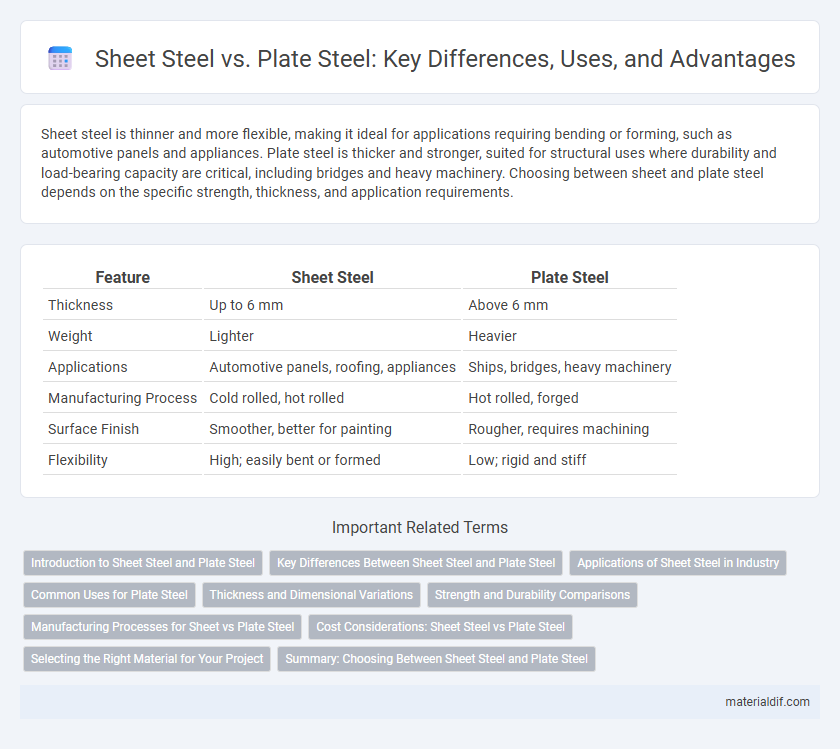

Table of Comparison

| Feature | Sheet Steel | Plate Steel |

|---|---|---|

| Thickness | Up to 6 mm | Above 6 mm |

| Weight | Lighter | Heavier |

| Applications | Automotive panels, roofing, appliances | Ships, bridges, heavy machinery |

| Manufacturing Process | Cold rolled, hot rolled | Hot rolled, forged |

| Surface Finish | Smoother, better for painting | Rougher, requires machining |

| Flexibility | High; easily bent or formed | Low; rigid and stiff |

Introduction to Sheet Steel and Plate Steel

Sheet steel refers to thin, flat pieces of steel typically less than 6 mm thick, commonly used in automotive bodies, appliances, and roofing due to its formability and lightweight properties. Plate steel, thicker than 6 mm, is designed for structural applications such as bridges, ship hulls, and heavy machinery where strength and durability are critical. Both materials undergo precise processing to meet specific mechanical and chemical standards for their varied industrial uses.

Key Differences Between Sheet Steel and Plate Steel

Sheet steel is characterized by its thinner gauge, typically less than 6 mm, making it highly suitable for applications requiring flexibility and formability such as automotive panels and roofing. Plate steel is thicker than 6 mm, providing greater strength and durability for heavy-duty uses in structural frameworks, bridges, and industrial equipment. The manufacturing processes differ as sheet steel is often cold rolled for a smoother finish, whereas plate steel is usually hot rolled to enhance mechanical properties and toughness.

Applications of Sheet Steel in Industry

Sheet steel is commonly used in automotive manufacturing for body panels due to its flexibility, lightweight properties, and ease of forming. In construction, sheet steel is essential for roofing, cladding, and ductwork, providing durability and corrosion resistance. Electronics and appliance industries utilize sheet steel for enclosures and cabinetry, benefiting from its smooth surface finish and strength.

Common Uses for Plate Steel

Plate steel is commonly used in heavy-duty applications such as shipbuilding, construction of bridges, and manufacturing of industrial machinery due to its thickness and strength. Its robust properties make it ideal for structural components, pressure vessels, and heavy equipment that require high load-bearing capacity. The material's durability ensures longevity and resistance to wear in demanding environments.

Thickness and Dimensional Variations

Sheet steel typically measures less than 6 mm in thickness and is available in coils or cut-to-length sheets, offering consistent dimensional tolerances suitable for automotive and appliance manufacturing. Plate steel, starting from 6 mm and extending to several inches thick, features greater dimensional variability to accommodate heavy structural applications like shipbuilding and construction. Thickness distinctions between sheet and plate steel directly impact mechanical properties, fabrication methods, and industry-specific suitability.

Strength and Durability Comparisons

Sheet steel typically exhibits moderate strength and flexibility, making it ideal for applications requiring lightweight yet durable materials, such as automotive body panels and household appliances. Plate steel offers significantly higher strength and superior durability due to its greater thickness, commonly used in heavy-duty construction, shipbuilding, and structural components subject to high stress. The enhanced mechanical properties of plate steel result from tighter grain structures and heat treatments, ensuring better impact resistance and longer service life compared to sheet steel.

Manufacturing Processes for Sheet vs Plate Steel

Sheet steel is typically produced through hot rolling followed by cold rolling processes to achieve thin, uniform thicknesses suitable for applications such as automotive bodies and appliances. Plate steel undergoes hot rolling as the primary manufacturing method, resulting in thicker, heavier sheets designed for construction, shipbuilding, and heavy machinery. The difference in rolling temperatures, thickness ranges, and finishing techniques distinguish sheet steel from plate steel in terms of manufacturing and end-use performance.

Cost Considerations: Sheet Steel vs Plate Steel

Sheet steel generally costs less than plate steel due to its thinner gauge and simpler manufacturing processes, making it ideal for applications requiring lightweight and cost-effective materials. Plate steel involves thicker, more durable material with higher production and handling costs, suitable for heavy-duty structural and industrial uses. Understanding the price difference helps optimize project budgets by selecting the appropriate steel type based on thickness, strength requirements, and overall application needs.

Selecting the Right Material for Your Project

Sheet steel offers thinner, more flexible properties ideal for applications requiring ease of bending and precise forming, commonly used in automotive and appliance manufacturing. Plate steel provides greater thickness and strength, making it suitable for structural components, heavy machinery, and construction projects demanding high durability. Choosing between sheet and plate steel depends on project specifications such as load-bearing requirements, fabrication methods, and desired finish quality.

Summary: Choosing Between Sheet Steel and Plate Steel

Sheet steel offers thinner, more flexible material typically used for automotive bodies and appliances, while plate steel provides thicker, heavier-duty options ideal for construction and heavy machinery. Selecting between sheet and plate steel depends on the specific application's requirements for strength, thickness, and formability. Understanding these differences ensures optimal performance in manufacturing and structural projects.

Sheet Steel vs Plate Steel Infographic

materialdif.com

materialdif.com