Powder coated steel offers a more durable and corrosion-resistant finish compared to painted steel, making it ideal for outdoor and heavy-use applications. The powder coating process creates a thicker and more uniform layer that resists chipping, scratching, and fading over time. Painted steel, while often cheaper and quicker to apply, typically requires more frequent maintenance and touch-ups to maintain its protective and aesthetic qualities.

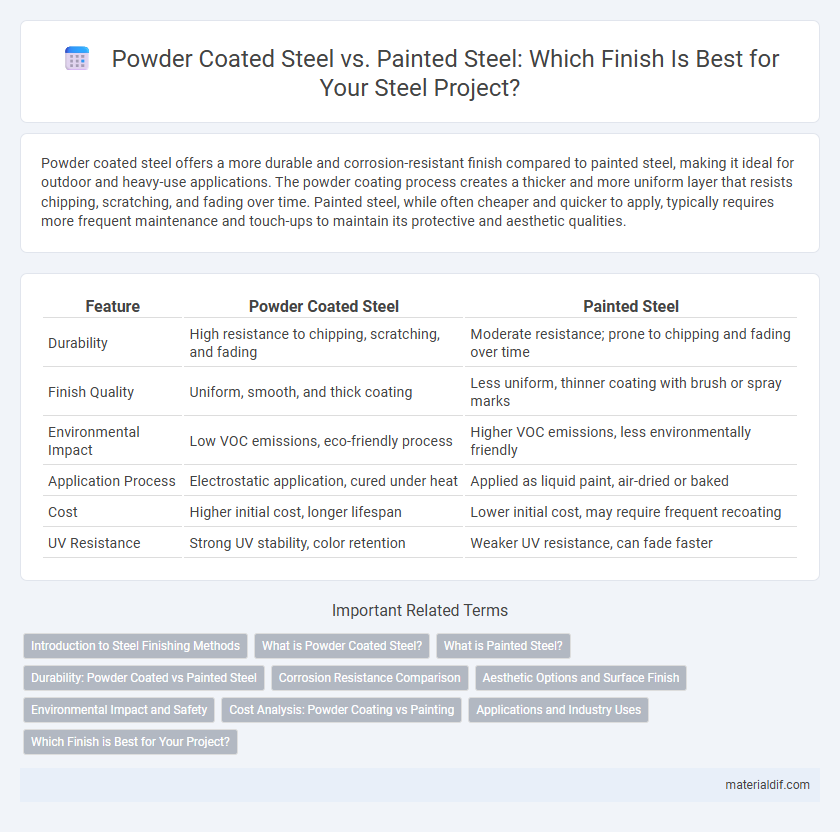

Table of Comparison

| Feature | Powder Coated Steel | Painted Steel |

|---|---|---|

| Durability | High resistance to chipping, scratching, and fading | Moderate resistance; prone to chipping and fading over time |

| Finish Quality | Uniform, smooth, and thick coating | Less uniform, thinner coating with brush or spray marks |

| Environmental Impact | Low VOC emissions, eco-friendly process | Higher VOC emissions, less environmentally friendly |

| Application Process | Electrostatic application, cured under heat | Applied as liquid paint, air-dried or baked |

| Cost | Higher initial cost, longer lifespan | Lower initial cost, may require frequent recoating |

| UV Resistance | Strong UV stability, color retention | Weaker UV resistance, can fade faster |

Introduction to Steel Finishing Methods

Powder coated steel offers a durable, uniform finish created by applying dry powder and curing it under heat, resulting in a thicker, more protective layer compared to traditional painted steel. Painted steel uses liquid paint that can be applied with brushes or spray methods, providing a versatile range of colors but typically less resistance to chipping and corrosion. Both finishing methods enhance steel's longevity and aesthetic appeal, with powder coating favored for industrial applications and painted finishes common in residential or decorative projects.

What is Powder Coated Steel?

Powder coated steel is a type of steel that has been coated with a dry powder composed of pigments and resins, which is then cured under heat to form a tough, durable finish. This coating process provides superior resistance to chipping, scratching, fading, and corrosion compared to traditional painted steel. The result is a long-lasting, uniform surface that enhances both the aesthetic appeal and protective qualities of steel products.

What is Painted Steel?

Painted steel is a type of steel coated with liquid paint that dries to form a protective and decorative layer, enhancing corrosion resistance and aesthetic appeal. This coating typically involves multiple layers, including primers and topcoats, to ensure durability and adhesion. Painted steel is widely used in construction, automotive, and appliance industries due to its versatility and cost-effectiveness compared to other finishes.

Durability: Powder Coated vs Painted Steel

Powder coated steel offers superior durability compared to painted steel due to its thicker, more uniform coating that resists chipping, scratching, and fading. The electrostatically applied powder creates a harder finish that withstands harsh weather conditions and corrosion more effectively than traditional liquid paint. This enhanced durability makes powder coated steel ideal for outdoor applications requiring long-lasting protection.

Corrosion Resistance Comparison

Powder coated steel offers superior corrosion resistance compared to painted steel due to its thicker, uniform coating that forms a hard, protective barrier against moisture and environmental contaminants. The electrostatically applied powder coating is baked onto the steel surface, creating a more durable and longer-lasting finish that resists chipping, rust, and fading better than conventional paint layers. This enhanced corrosion resistance makes powder coated steel ideal for outdoor applications and harsh environments where steel longevity is critical.

Aesthetic Options and Surface Finish

Powder coated steel offers a more durable and uniform surface finish that resists chipping, fading, and scratching better than painted steel, enhancing long-term aesthetic appeal. It provides a wider range of vibrant colors and textures, including matte, gloss, and metallic finishes, allowing for versatile design options. Painted steel, while sometimes offering a smoother and glossier finish initially, tends to require more frequent maintenance to preserve its appearance.

Environmental Impact and Safety

Powder coated steel offers superior environmental benefits compared to painted steel, as it emits negligible volatile organic compounds (VOCs) during application, reducing air pollution and health hazards. The durable, chemical-resistant finish of powder coating also minimizes the need for frequent recoating, leading to less waste and resource consumption over the product lifecycle. In terms of safety, powder coating processes are typically free of hazardous solvents, lowering risks to workers and end-users, while painted steel often requires solvent-based paints that pose fire and toxicity concerns.

Cost Analysis: Powder Coating vs Painting

Powder coated steel generally offers a higher upfront cost compared to traditional painted steel due to the specialized equipment and materials required. However, powder coating provides superior durability and resistance to wear, reducing long-term maintenance and repainting expenses. The overall cost analysis favors powder coating for projects prioritizing longevity and lower lifecycle costs despite its initial premium.

Applications and Industry Uses

Powder coated steel offers superior durability and corrosion resistance, making it ideal for outdoor applications in industries such as automotive, construction, and appliances. Painted steel, while often more cost-effective and versatile in color options, is typically preferred for indoor environments like furniture manufacturing and decorative architectural elements. Both finishes serve critical roles, with powder coating excelling in long-term exposure scenarios and painted steel favored for aesthetic customization and easier touch-ups.

Which Finish is Best for Your Project?

Powder coated steel offers superior durability, resistance to chipping, fading, and corrosion compared to painted steel, making it ideal for outdoor and high-wear applications. Painted steel provides a smoother finish with more color options but typically requires more maintenance and touch-ups over time. Choosing the best finish depends on project requirements such as environmental exposure, longevity, and budget constraints.

Powder Coated Steel vs Painted Steel Infographic

materialdif.com

materialdif.com