Low-carbon steel pet products offer greater flexibility and corrosion resistance, making them ideal for everyday use and environments requiring durability without brittleness. High-carbon steel pet items provide enhanced strength and wear resistance, suitable for applications demanding high impact tolerance and longevity. Choosing between low-carbon and high-carbon steel depends on balancing the need for toughness versus hardness in pet-related applications.

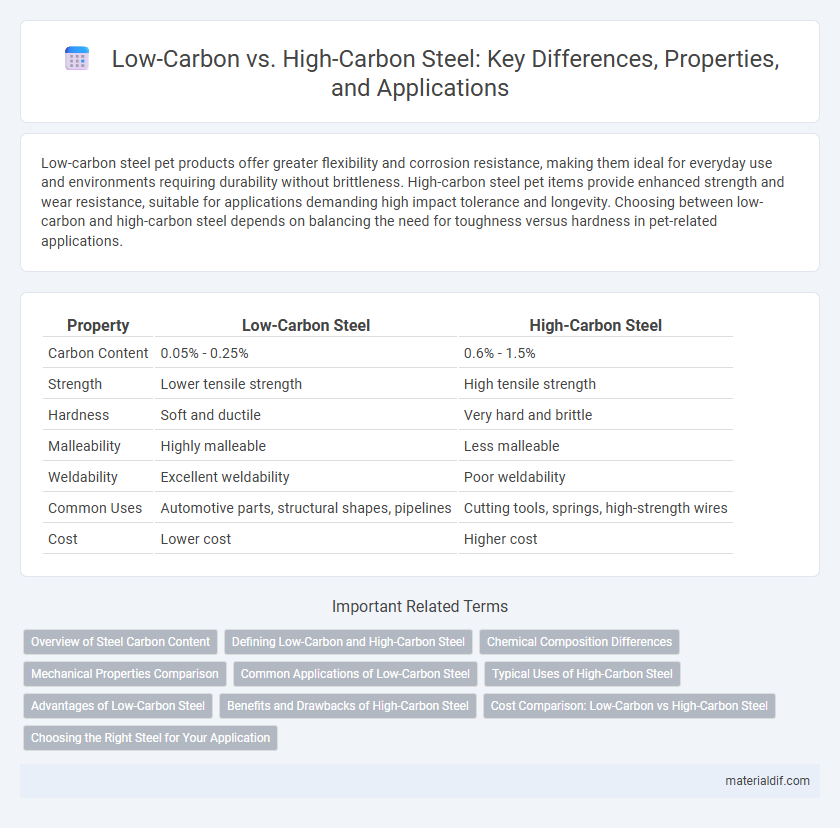

Table of Comparison

| Property | Low-Carbon Steel | High-Carbon Steel |

|---|---|---|

| Carbon Content | 0.05% - 0.25% | 0.6% - 1.5% |

| Strength | Lower tensile strength | High tensile strength |

| Hardness | Soft and ductile | Very hard and brittle |

| Malleability | Highly malleable | Less malleable |

| Weldability | Excellent weldability | Poor weldability |

| Common Uses | Automotive parts, structural shapes, pipelines | Cutting tools, springs, high-strength wires |

| Cost | Lower cost | Higher cost |

Overview of Steel Carbon Content

Steel carbon content significantly influences its properties, with low-carbon steel containing up to 0.3% carbon, offering enhanced ductility and weldability, making it ideal for structural applications. High-carbon steel, ranging from 0.6% to 1.0% carbon, provides superior hardness and strength but reduced flexibility, suitable for cutting tools and wear-resistant products. Understanding carbon levels helps optimize steel selection based on mechanical performance and practical use.

Defining Low-Carbon and High-Carbon Steel

Low-carbon steel contains approximately 0.05% to 0.25% carbon, making it ductile and easy to weld, ideal for automotive panels and construction materials. High-carbon steel features carbon content between 0.6% and 1.0%, resulting in increased hardness and strength, commonly used for cutting tools and springs. The carbon content directly influences the steel's mechanical properties, wear resistance, and applications.

Chemical Composition Differences

Low-carbon steel contains approximately 0.05% to 0.25% carbon, resulting in increased ductility and weldability, while high-carbon steel has a carbon content ranging from 0.6% to 1.5%, providing higher hardness and tensile strength. The presence of manganese, silicon, and traces of other elements further influence the mechanical properties and chemical stability of both steel types. Understanding the precise carbon content and alloying elements is essential for selecting the appropriate steel grade for specific industrial applications.

Mechanical Properties Comparison

Low-carbon steel typically contains less than 0.3% carbon, resulting in lower tensile strength but higher ductility and weldability compared to high-carbon steel, which contains 0.6% to 1.0% carbon and exhibits greater hardness and tensile strength but reduced flexibility. The mechanical properties of low-carbon steel make it suitable for applications requiring formability and impact resistance, whereas high-carbon steel is preferred for tools and wear-resistant surfaces due to its superior hardness and fatigue strength. Tensile strength for low-carbon steel generally ranges from 370 to 470 MPa, while high-carbon steel can exceed 800 MPa, demonstrating a significant increase in mechanical performance with higher carbon content.

Common Applications of Low-Carbon Steel

Low-carbon steel, containing less than 0.3% carbon, is widely used in automotive body panels, structural components, and pipelines due to its excellent ductility and weldability. Its low carbon content allows for easier forming and machining, making it ideal for manufacturing appliances and furniture frames. In contrast to high-carbon steel, low-carbon steel's strength and flexibility make it a preferred choice for construction and manufacturing industries requiring reliable yet cost-effective materials.

Typical Uses of High-Carbon Steel

High-carbon steel is predominantly used in applications requiring superior hardness and strength, such as cutting tools, blades, springs, and high-strength wires. Its carbon content, typically between 0.6% and 1.0%, provides enhanced wear resistance and durability, making it ideal for industrial machinery and automotive components. The material's ability to retain a sharp edge and withstand heavy mechanical stress is crucial for manufacturing tools and heavy-duty equipment.

Advantages of Low-Carbon Steel

Low-carbon steel offers superior ductility and weldability compared to high-carbon steel, making it ideal for automotive and construction applications requiring formability. Its lower carbon content enhances corrosion resistance, contributing to longer material lifespan in structural uses. Cost-effectiveness and easier machinability further support its widespread adoption in manufacturing and fabrication industries.

Benefits and Drawbacks of High-Carbon Steel

High-carbon steel contains approximately 0.6% to 1.4% carbon, offering superior hardness, tensile strength, and wear resistance compared to low-carbon steel, making it ideal for cutting tools, springs, and high-strength wires. Its increased carbon content enhances durability but reduces ductility and weldability, leading to higher brittleness and susceptibility to cracking under stress. This trade-off limits its applications where flexibility is crucial, but high-carbon steel remains essential in industries demanding extreme strength and abrasion resistance.

Cost Comparison: Low-Carbon vs High-Carbon Steel

Low-carbon steel typically costs more than high-carbon steel due to its higher demand in automotive and construction industries requiring malleability and weldability. High-carbon steel is generally less expensive as it contains more carbon, enhancing hardness and strength but making it less ductile and versatile. The cost differential reflects material properties influencing manufacturing processes and end-use applications.

Choosing the Right Steel for Your Application

Low-carbon steel offers excellent weldability and ductility, making it ideal for automotive bodies and structural components where formability is crucial. High-carbon steel provides superior hardness and strength, suitable for cutting tools and high-wear applications requiring durability. Selecting the right steel depends on the balance between mechanical properties and the specific performance demands of the intended use.

Low-carbon vs High-carbon Infographic

materialdif.com

materialdif.com