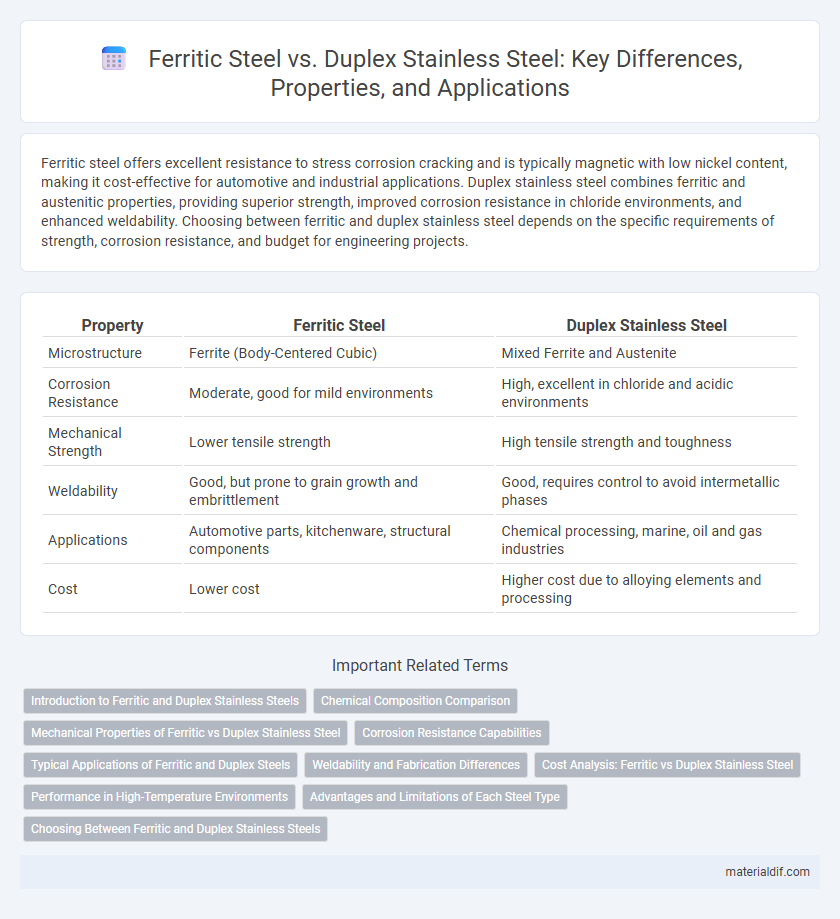

Ferritic steel offers excellent resistance to stress corrosion cracking and is typically magnetic with low nickel content, making it cost-effective for automotive and industrial applications. Duplex stainless steel combines ferritic and austenitic properties, providing superior strength, improved corrosion resistance in chloride environments, and enhanced weldability. Choosing between ferritic and duplex stainless steel depends on the specific requirements of strength, corrosion resistance, and budget for engineering projects.

Table of Comparison

| Property | Ferritic Steel | Duplex Stainless Steel |

|---|---|---|

| Microstructure | Ferrite (Body-Centered Cubic) | Mixed Ferrite and Austenite |

| Corrosion Resistance | Moderate, good for mild environments | High, excellent in chloride and acidic environments |

| Mechanical Strength | Lower tensile strength | High tensile strength and toughness |

| Weldability | Good, but prone to grain growth and embrittlement | Good, requires control to avoid intermetallic phases |

| Applications | Automotive parts, kitchenware, structural components | Chemical processing, marine, oil and gas industries |

| Cost | Lower cost | Higher cost due to alloying elements and processing |

Introduction to Ferritic and Duplex Stainless Steels

Ferritic stainless steels contain 10.5% to 27% chromium and have a body-centered cubic (BCC) crystal structure, offering excellent corrosion resistance and magnetic properties. Duplex stainless steels combine approximately equal proportions of ferritic and austenitic phases, typically with 22% chromium, 5-6% nickel, and 3% molybdenum, delivering superior strength and enhanced resistance to stress corrosion cracking. Both steel types find widespread use in chemical processing, automotive, and construction industries due to their distinct microstructures and mechanical properties.

Chemical Composition Comparison

Ferritic steel primarily consists of 10-30% chromium with minimal nickel content, enhancing its corrosion resistance and magnetic properties. Duplex stainless steel contains roughly 20-28% chromium, 4-6% nickel, and 2-5% molybdenum, offering superior strength and corrosion resistance through a balanced austenitic-ferritic microstructure. The higher nickel and molybdenum percentages in duplex stainless steel contribute to improved pitting and stress corrosion cracking resistance compared to ferritic steel.

Mechanical Properties of Ferritic vs Duplex Stainless Steel

Ferritic steel exhibits moderate tensile strength and good ductility, making it suitable for applications requiring corrosion resistance and magnetic properties. Duplex stainless steel combines the high strength of ferritic steel with the excellent toughness and corrosion resistance of austenitic steel, resulting in superior yield strength--typically twice that of ferritic grades. The microstructure of duplex stainless steel offers enhanced resistance to stress corrosion cracking and better fatigue performance compared to ferritic steel.

Corrosion Resistance Capabilities

Ferritic steel exhibits moderate corrosion resistance due to its iron-chromium alloy composition, typically containing 10.5% to 27% chromium, which enhances its resistance to oxidation and stress corrosion cracking in mildly corrosive environments. Duplex stainless steel, a blend of austenitic and ferritic structures with 20% to 28% chromium and 4% to 6% nickel, offers superior corrosion resistance, particularly against chloride-induced pitting and crevice corrosion, making it ideal for marine and chemical processing applications. The dual-phase microstructure of duplex steel provides enhanced mechanical strength and improved resistance to stress corrosion cracking compared to ferritic grades.

Typical Applications of Ferritic and Duplex Steels

Ferritic steel is commonly used in automotive exhaust systems, kitchen appliances, and architectural structures due to its excellent corrosion resistance and magnetic properties. Duplex stainless steel finds typical applications in chemical processing, marine environments, and oil and gas industries, where its superior strength and resistance to stress corrosion cracking are critical. Both steels offer specialized performance tailored to demanding industrial uses.

Weldability and Fabrication Differences

Ferritic steel offers moderate weldability with low thermal expansion and good resistance to stress corrosion cracking, making it suitable for automotive and structural applications but requiring precise control of heat input to avoid brittleness. Duplex stainless steel exhibits superior weldability due to its balanced microstructure of austenite and ferrite, providing enhanced strength and corrosion resistance while reducing the risk of weld-induced cracking and distortion. Fabrication of duplex stainless steel demands careful pre- and post-weld heat treatments to maintain phase balance, whereas ferritic steel fabrication is generally less complex but more sensitive to weld heat input and cooling rates.

Cost Analysis: Ferritic vs Duplex Stainless Steel

Ferritic steel generally offers a lower initial cost compared to duplex stainless steel due to its simpler alloy composition and reduced nickel content. Duplex stainless steel, containing higher amounts of chromium, molybdenum, and nickel, provides superior corrosion resistance and mechanical strength, which can lead to lower maintenance and replacement costs over the asset's lifecycle. When evaluating total cost of ownership, duplex stainless steel's enhanced durability often justifies its higher upfront expense, especially in aggressive environments requiring long-term reliability.

Performance in High-Temperature Environments

Ferritic steel offers good resistance to oxidation and thermal fatigue at temperatures up to 600degC, making it suitable for moderately high-temperature applications. Duplex stainless steel exhibits superior mechanical strength and corrosion resistance, maintaining stability in harsh, high-temperature environments up to 800degC. The enhanced chromium and molybdenum content in duplex stainless steel significantly improves its performance under sustained thermal stress compared to ferritic steel.

Advantages and Limitations of Each Steel Type

Ferritic steel offers excellent resistance to stress corrosion cracking and good thermal conductivity, making it ideal for automotive and industrial applications where magnetic properties are beneficial; however, it has lower strength and toughness compared to other stainless steels. Duplex stainless steel combines the best properties of ferritic and austenitic steels, including high strength, superior corrosion resistance, especially in chloride environments, and good weldability, but its higher cost and complex heat treatment requirements can limit its use. Both steels serve niche applications where their unique advantages are critical, with ferritic steels favored for cost-sensitive, magnetic applications and duplex stainless steels chosen for demanding, corrosive environments.

Choosing Between Ferritic and Duplex Stainless Steels

Ferritic stainless steel offers excellent resistance to stress corrosion cracking and is more cost-effective for applications requiring good corrosion resistance and magnetic properties. Duplex stainless steel combines austenitic and ferritic phases, providing superior strength, enhanced corrosion resistance, especially against chloride stress corrosion, and improved weldability. Selecting between ferritic and duplex stainless steels depends on application demands for strength, corrosion resistance in aggressive environments, and economic considerations.

Ferritic Steel vs Duplex Stainless Steel Infographic

materialdif.com

materialdif.com