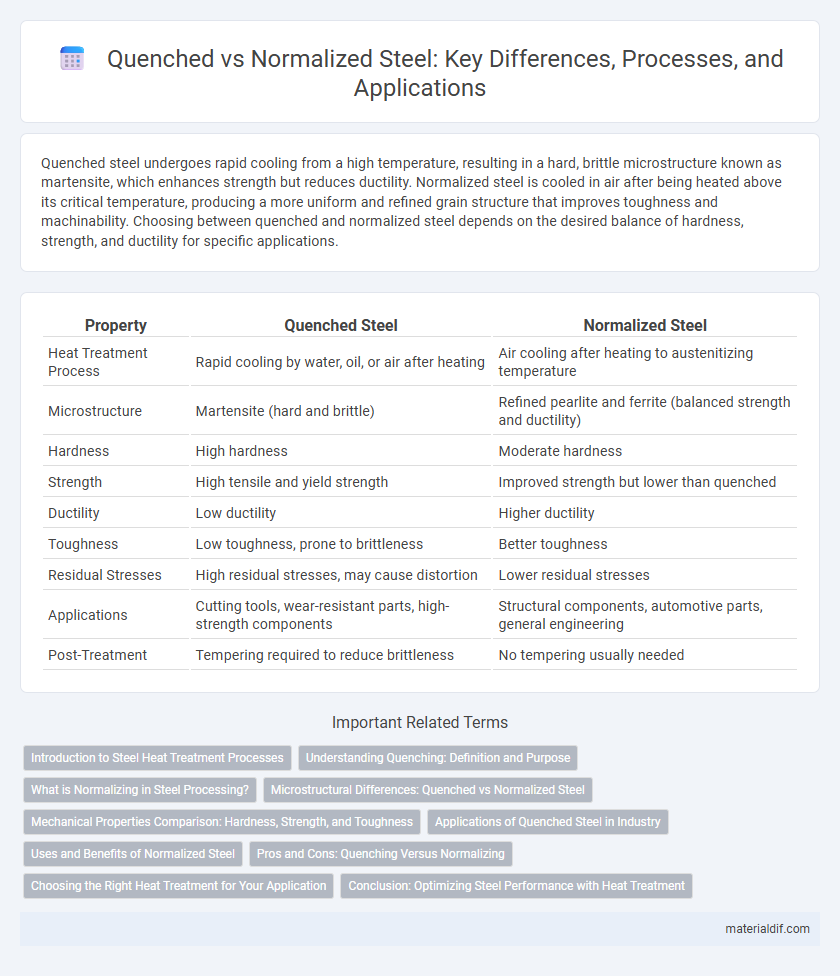

Quenched steel undergoes rapid cooling from a high temperature, resulting in a hard, brittle microstructure known as martensite, which enhances strength but reduces ductility. Normalized steel is cooled in air after being heated above its critical temperature, producing a more uniform and refined grain structure that improves toughness and machinability. Choosing between quenched and normalized steel depends on the desired balance of hardness, strength, and ductility for specific applications.

Table of Comparison

| Property | Quenched Steel | Normalized Steel |

|---|---|---|

| Heat Treatment Process | Rapid cooling by water, oil, or air after heating | Air cooling after heating to austenitizing temperature |

| Microstructure | Martensite (hard and brittle) | Refined pearlite and ferrite (balanced strength and ductility) |

| Hardness | High hardness | Moderate hardness |

| Strength | High tensile and yield strength | Improved strength but lower than quenched |

| Ductility | Low ductility | Higher ductility |

| Toughness | Low toughness, prone to brittleness | Better toughness |

| Residual Stresses | High residual stresses, may cause distortion | Lower residual stresses |

| Applications | Cutting tools, wear-resistant parts, high-strength components | Structural components, automotive parts, general engineering |

| Post-Treatment | Tempering required to reduce brittleness | No tempering usually needed |

Introduction to Steel Heat Treatment Processes

Quenching and normalizing are essential steel heat treatment processes that alter the microstructure to enhance mechanical properties. Quenching rapidly cools heated steel in water or oil, producing a hard but brittle martensitic structure. Normalizing involves air cooling from austenitizing temperature, resulting in refined grain size and improved toughness with a more uniform microstructure.

Understanding Quenching: Definition and Purpose

Quenching is a heat treatment process where steel is rapidly cooled from a high temperature, typically using water, oil, or air, to increase hardness and strength by transforming its microstructure into martensite. This rapid cooling prevents the formation of softer phases like pearlite or ferrite, resulting in enhanced wear resistance and tensile strength. Understanding quenching helps optimize steel performance for applications requiring durability and toughness under stress.

What is Normalizing in Steel Processing?

Normalizing in steel processing is a heat treatment technique where steel is heated to a temperature above its critical point and then air-cooled to refine its grain structure and enhance mechanical properties. This process improves toughness, machinability, and uniformity by relieving internal stresses while producing a more homogeneous microstructure compared to quenched steel. Normalized steel exhibits balanced strength and ductility, making it ideal for structural components requiring consistent performance under varying loads.

Microstructural Differences: Quenched vs Normalized Steel

Quenched steel features a martensitic microstructure formed by rapid cooling, resulting in a hard and brittle texture with high tensile strength. Normalized steel exhibits a more refined and uniform grain structure composed mainly of ferrite and pearlite, enhancing toughness and ductility. The distinct transformation mechanisms during cooling define the performance characteristics critical for applications requiring either hardness or toughness.

Mechanical Properties Comparison: Hardness, Strength, and Toughness

Quenched steel exhibits higher hardness and tensile strength due to rapid cooling, resulting in a martensitic microstructure that enhances wear resistance but reduces toughness. Normalized steel, cooled in air, offers a balanced combination of moderate hardness, improved ductility, and greater toughness, making it more suitable for dynamic loading conditions. The mechanical properties of quenched steel favor applications requiring maximum strength, while normalized steel is preferred for components requiring better impact resistance and fatigue performance.

Applications of Quenched Steel in Industry

Quenched steel, characterized by its high hardness and tensile strength due to rapid cooling, is widely used in the automotive industry for manufacturing gears, crankshafts, and axles that require superior wear resistance. In the aerospace sector, quenched steel components are essential for engine parts and structural elements demanding high durability and fatigue resistance. Additionally, heavy machinery and construction equipment rely on quenched steel for parts like cutting tools and drill bits that must withstand intense mechanical stresses.

Uses and Benefits of Normalized Steel

Normalized steel offers improved machinability and uniform mechanical properties, making it ideal for structural components and automotive parts requiring reliability under stress. Its refined grain structure enhances toughness and reduces residual stress compared to quenched steel, promoting better dimensional stability during manufacturing. Widely used in pipelines, machinery, and construction, normalized steel balances strength and ductility for versatile industrial applications.

Pros and Cons: Quenching Versus Normalizing

Quenching enhances steel hardness and strength by rapid cooling, but increases brittleness and residual stress, requiring careful tempering to avoid fractures. Normalizing refines grain structure and improves toughness and machinability, yet produces lower hardness compared to quenched steel, making it suitable for parts needing a balance of strength and ductility. Selection between quenching and normalizing depends on the desired mechanical properties and application-specific performance requirements.

Choosing the Right Heat Treatment for Your Application

Selecting the appropriate heat treatment depends on the required mechanical properties and application environment of steel components. Quenching rapidly cools steel, producing a hard, brittle microstructure ideal for wear resistance and high-strength applications, while normalization refines grain structure to improve toughness and machinability with less risk of distortion. Understanding the trade-offs between quenched hardness and normalized ductility ensures optimal performance and service life in manufacturing and structural uses.

Conclusion: Optimizing Steel Performance with Heat Treatment

Quenching steel rapidly cools it from a high temperature, producing a hard and brittle microstructure ideal for wear resistance, while normalization refines grain size through controlled cooling, enhancing toughness and uniformity. Choosing quenching is optimal for applications requiring maximum hardness and strength, whereas normalization suits components needing balanced mechanical properties and improved machinability. Tailoring heat treatment methods enables engineers to optimize steel performance for specific uses, ensuring durability and functionality under diverse operating conditions.

Quenched vs Normalized Infographic

materialdif.com

materialdif.com