Martensitic steel offers high strength and hardness due to its body-centered tetragonal crystal structure formed by rapid cooling, making it ideal for cutting tools and wear-resistant applications. Austenitic steel, characterized by its face-centered cubic structure, provides superior corrosion resistance and excellent ductility, commonly used in chemical and food processing industries. The choice between martensitic and austenitic steel depends on the balance required between mechanical strength and corrosion resistance.

Table of Comparison

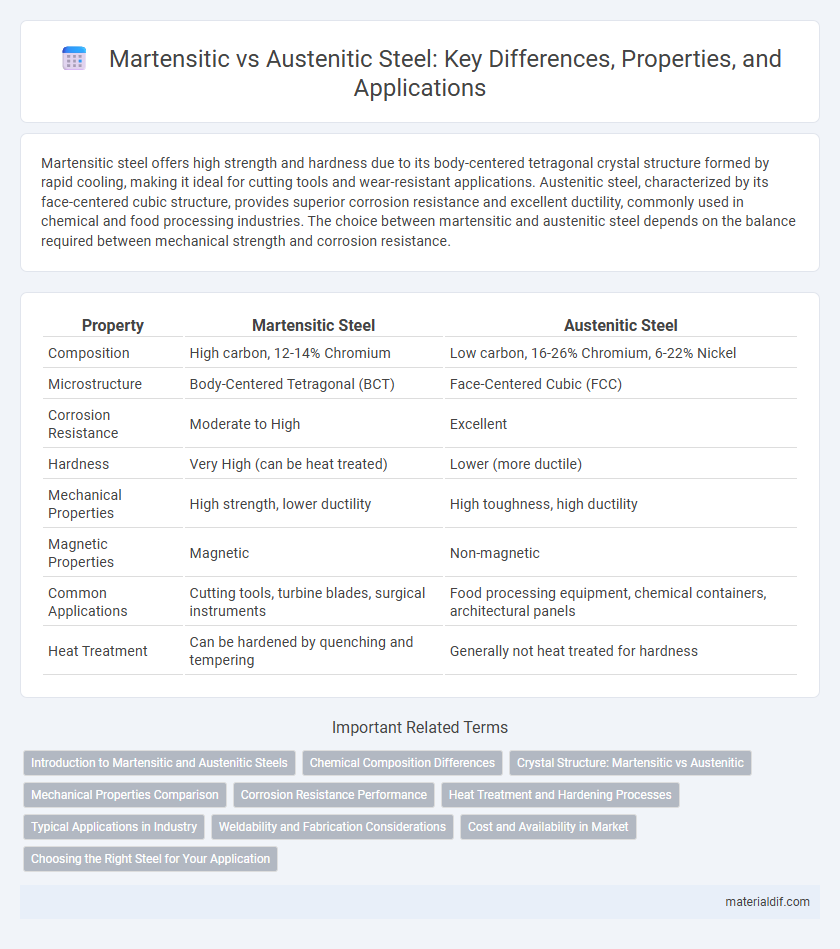

| Property | Martensitic Steel | Austenitic Steel |

|---|---|---|

| Composition | High carbon, 12-14% Chromium | Low carbon, 16-26% Chromium, 6-22% Nickel |

| Microstructure | Body-Centered Tetragonal (BCT) | Face-Centered Cubic (FCC) |

| Corrosion Resistance | Moderate to High | Excellent |

| Hardness | Very High (can be heat treated) | Lower (more ductile) |

| Mechanical Properties | High strength, lower ductility | High toughness, high ductility |

| Magnetic Properties | Magnetic | Non-magnetic |

| Common Applications | Cutting tools, turbine blades, surgical instruments | Food processing equipment, chemical containers, architectural panels |

| Heat Treatment | Can be hardened by quenching and tempering | Generally not heat treated for hardness |

Introduction to Martensitic and Austenitic Steels

Martensitic steels are characterized by their high carbon content and ability to harden through heat treatment, offering exceptional strength and wear resistance ideal for cutting tools and blades. Austenitic steels contain higher chromium and nickel levels, providing superior corrosion resistance and excellent toughness, widely used in chemical processing and food industry equipment. Both steel types play crucial roles in industrial applications, balancing hardness and corrosion resistance based on their microstructural transformations.

Chemical Composition Differences

Martensitic steels typically contain higher carbon content, ranging from 0.1% to 1.2%, with low amounts of chromium (12-14%) and minimal nickel, enhancing hardness and wear resistance. Austenitic steels have lower carbon levels, generally below 0.1%, but higher chromium (16-26%) and significant nickel content (6-22%), which stabilize the face-centered cubic (FCC) structure and improve corrosion resistance. The distinct variations in carbon, chromium, and nickel content directly influence the microstructure and mechanical properties of these steel types.

Crystal Structure: Martensitic vs Austenitic

Martensitic steel features a body-centered tetragonal (BCT) crystal structure formed through rapid quenching, which imparts high hardness and strength due to the distorted lattice and trapped carbon atoms. Austenitic steel exhibits a face-centered cubic (FCC) crystal structure, providing enhanced ductility and corrosion resistance by allowing more slip systems and a stable lattice at room temperature. The contrasting crystal structures directly influence the mechanical properties and applications of martensitic and austenitic steels.

Mechanical Properties Comparison

Martensitic steel exhibits high hardness and strength due to its body-centered tetragonal (BCT) crystal structure, making it ideal for applications requiring wear resistance and durability. Austenitic steel, characterized by its face-centered cubic (FCC) structure, offers superior ductility, toughness, and corrosion resistance but lower strength compared to martensitic grades. The mechanical properties of martensitic steel include tensile strength typically above 1,200 MPa with lower elongation, whereas austenitic steel provides moderate tensile strength around 600-900 MPa with elongation exceeding 40%.

Corrosion Resistance Performance

Martensitic stainless steel exhibits moderate corrosion resistance due to its higher carbon content and martensitic microstructure, making it suitable for applications with moderate environmental exposure. Austenitic stainless steel offers superior corrosion resistance, attributed to its high chromium and nickel content and face-centered cubic crystal structure, enhancing resistance to pitting, crevice corrosion, and oxidation. The enhanced corrosion resistance of austenitic grades like 304 and 316 stainless steel makes them ideal for harsh chemical and marine environments compared to martensitic grades such as 410 and 420.

Heat Treatment and Hardening Processes

Martensitic steels undergo heat treatment involving rapid quenching from the austenitizing temperature, transforming austenite into a hard, brittle martensitic structure that significantly increases hardness and tensile strength. Austenitic steels, typically non-magnetic and high in chromium and nickel, do not harden by heat treatment but rely on cold working to enhance strength and hardness. The hardening process in martensitic steels is critical for applications requiring wear resistance, while austenitic steels prioritize corrosion resistance and toughness without heat-induced hardening.

Typical Applications in Industry

Martensitic steel, known for its high hardness and strength, is commonly used in cutting tools, surgical instruments, and aerospace components requiring wear resistance. Austenitic steel, characterized by excellent corrosion resistance and ductility, finds typical applications in chemical processing equipment, food industry machinery, and marine environments. Both types serve critical roles in manufacturing where specific mechanical properties and environmental durability are essential.

Weldability and Fabrication Considerations

Martensitic steels exhibit limited weldability due to their high carbon content, which increases the risk of cracking and requires preheating and controlled cooling during fabrication. Austenitic steels offer superior weldability with excellent resistance to cracking and distortion, attributed to their face-centered cubic crystal structure and lower carbon content. Fabrication of austenitic steels typically demands less stringent heat treatment, making them more suitable for complex welded assemblies in corrosive environments.

Cost and Availability in Market

Martensitic steel generally offers lower cost and higher availability in the market due to its simpler alloy composition and widespread use in cutlery and industrial applications. Austenitic steel, while more expensive, provides superior corrosion resistance and durability, which can justify its higher price in specialized sectors like food processing and medical instruments. The cost differential largely stems from the alloying elements such as higher nickel content in austenitic steel, impacting both production expense and market supply.

Choosing the Right Steel for Your Application

Martensitic steel offers high strength and hardness due to its carbon-rich, body-centered tetragonal structure, making it ideal for cutting tools, blades, and wear-resistant applications. Austenitic steel, characterized by a face-centered cubic structure and high chromium and nickel content, provides superior corrosion resistance and excellent toughness, suitable for chemical processing, food equipment, and medical devices. Selecting between martensitic and austenitic steel depends on balancing the need for hardness and wear resistance versus corrosion resistance and ductility in your specific application.

Martensitic vs Austenitic Infographic

materialdif.com

materialdif.com