Alloy steel contains added elements such as chromium, nickel, and molybdenum, which enhance its mechanical properties, corrosion resistance, and toughness compared to plain carbon steel. Plain carbon steel primarily consists of iron and carbon, offering good strength and wear resistance but lacking the enhanced attributes of alloy steel. Choosing between the two depends on the application's requirement for durability, strength, and resistance to environmental factors.

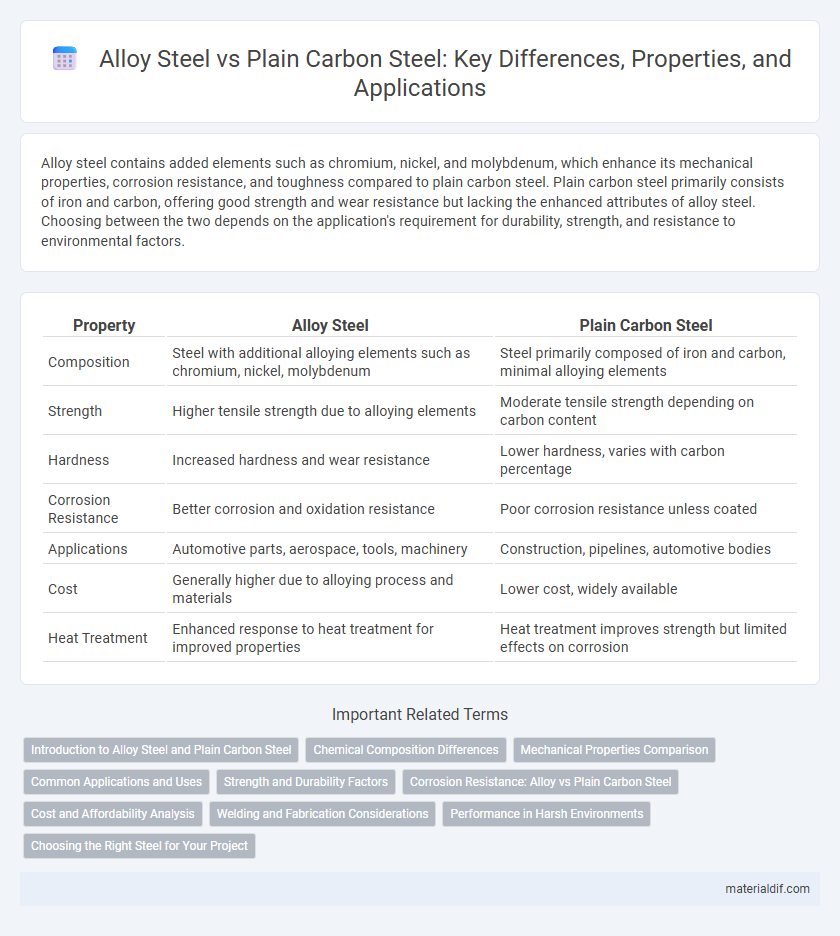

Table of Comparison

| Property | Alloy Steel | Plain Carbon Steel |

|---|---|---|

| Composition | Steel with additional alloying elements such as chromium, nickel, molybdenum | Steel primarily composed of iron and carbon, minimal alloying elements |

| Strength | Higher tensile strength due to alloying elements | Moderate tensile strength depending on carbon content |

| Hardness | Increased hardness and wear resistance | Lower hardness, varies with carbon percentage |

| Corrosion Resistance | Better corrosion and oxidation resistance | Poor corrosion resistance unless coated |

| Applications | Automotive parts, aerospace, tools, machinery | Construction, pipelines, automotive bodies |

| Cost | Generally higher due to alloying process and materials | Lower cost, widely available |

| Heat Treatment | Enhanced response to heat treatment for improved properties | Heat treatment improves strength but limited effects on corrosion |

Introduction to Alloy Steel and Plain Carbon Steel

Alloy steel contains additional elements such as chromium, nickel, and molybdenum, which enhance properties like strength, hardness, and corrosion resistance compared to plain carbon steel. Plain carbon steel primarily consists of iron and carbon, making it simpler in composition, typically offering good strength and ductility but limited corrosion resistance. The varied alloying elements in alloy steel allow for specialized applications in industries requiring superior mechanical and chemical properties.

Chemical Composition Differences

Alloy steel contains significant amounts of elements such as chromium, nickel, molybdenum, and vanadium, which enhance properties like strength, hardness, and corrosion resistance, whereas plain carbon steel mainly consists of iron and carbon with minimal alloying elements. The carbon content in plain carbon steel usually ranges from 0.05% to 2.0%, while alloy steel's carbon content varies depending on the specific alloy but is supplemented by other metals to achieve desired mechanical characteristics. These chemical composition differences make alloy steel suitable for specialized applications requiring higher performance compared to the more basic, cost-effective plain carbon steel.

Mechanical Properties Comparison

Alloy steel generally exhibits superior mechanical properties compared to plain carbon steel, including higher tensile strength, improved hardness, and enhanced toughness due to the presence of additional alloying elements such as chromium, nickel, and molybdenum. Plain carbon steel, primarily composed of iron and carbon, offers good ductility and weldability but usually lacks the enhanced wear resistance and corrosion resistance found in alloy steels. Mechanical performance differences make alloy steel preferable for applications requiring greater strength, impact resistance, and service life under demanding conditions.

Common Applications and Uses

Alloy steel is widely used in automotive components, aerospace parts, and heavy machinery due to its enhanced mechanical properties and corrosion resistance. Plain carbon steel is commonly utilized in construction, pipelines, and manufacturing of structural shapes, offering cost-effective strength for general applications. Industries prefer alloy steel for demanding environments, while plain carbon steel serves well in standard load-bearing tasks.

Strength and Durability Factors

Alloy steel contains additional elements such as chromium, nickel, and molybdenum, which significantly enhance its strength and durability compared to plain carbon steel. These alloying elements improve resistance to wear, corrosion, and high-temperature conditions, making alloy steel ideal for demanding applications. Plain carbon steel, while generally strong and cost-effective, lacks the enhanced mechanical properties found in alloy variants, resulting in lower durability under extreme stresses.

Corrosion Resistance: Alloy vs Plain Carbon Steel

Alloy steel exhibits superior corrosion resistance compared to plain carbon steel due to the inclusion of elements such as chromium, nickel, and molybdenum, which form protective oxide layers on the metal surface. Plain carbon steel lacks these alloying elements, making it more susceptible to rust and oxidation in harsh environments. This enhanced corrosion resistance makes alloy steel ideal for applications in chemical processing, marine, and outdoor structures where durability against environmental degradation is critical.

Cost and Affordability Analysis

Alloy steel generally incurs higher production costs due to the incorporation of elements like chromium, nickel, and molybdenum, which enhance strength and corrosion resistance but increase raw material expenses. Plain carbon steel is more affordable, making it ideal for budget-conscious applications requiring basic strength without specialized properties. Cost analysis reveals that alloy steel suits projects demanding durability and performance, while plain carbon steel remains cost-effective for general structural uses.

Welding and Fabrication Considerations

Alloy steel exhibits enhanced weldability compared to plain carbon steel due to its controlled chemical composition, which reduces the risk of cracking and distortion during welding. The presence of alloying elements such as chromium, nickel, and molybdenum in alloy steel improves hardness and corrosion resistance, requiring specific welding techniques like preheating and post-weld heat treatment to maintain structural integrity. Fabrication of plain carbon steel is generally more straightforward, but it may demand higher caution during welding to prevent issues like hydrogen-induced cracking and reduced ductility.

Performance in Harsh Environments

Alloy steel outperforms plain carbon steel in harsh environments due to its enhanced resistance to corrosion, oxidation, and extreme temperatures, achieved by adding elements like chromium, nickel, and molybdenum. Plain carbon steel, while strong and cost-effective, is more susceptible to rust and degradation when exposed to moisture and chemically aggressive conditions. The improved mechanical properties and durability of alloy steel make it the preferred choice for applications requiring long-term reliability and strength under severe environmental stresses.

Choosing the Right Steel for Your Project

Alloy steel offers enhanced mechanical properties such as improved toughness, strength, and corrosion resistance due to the addition of elements like chromium, nickel, and molybdenum, making it ideal for demanding applications. Plain carbon steel, primarily composed of iron and carbon, is cost-effective and suitable for projects requiring good weldability and moderate strength without specialized resistance. Selecting the right steel depends on project requirements for durability, environmental exposure, and budget constraints, where alloy steel fits high-performance needs and plain carbon steel suits general structural purposes.

Alloy Steel vs Plain Carbon Steel Infographic

materialdif.com

materialdif.com