Bar stock offers cylindrical shapes ideal for machining and structural applications requiring uniform strength, while flat stock provides rectangular or square profiles suited for fabrication and surface treatments. Choosing between bar stock and flat stock depends on the specific design requirements, load distribution, and manufacturing process. Both types are essential in steel pet manufacturing for creating durable and customized components.

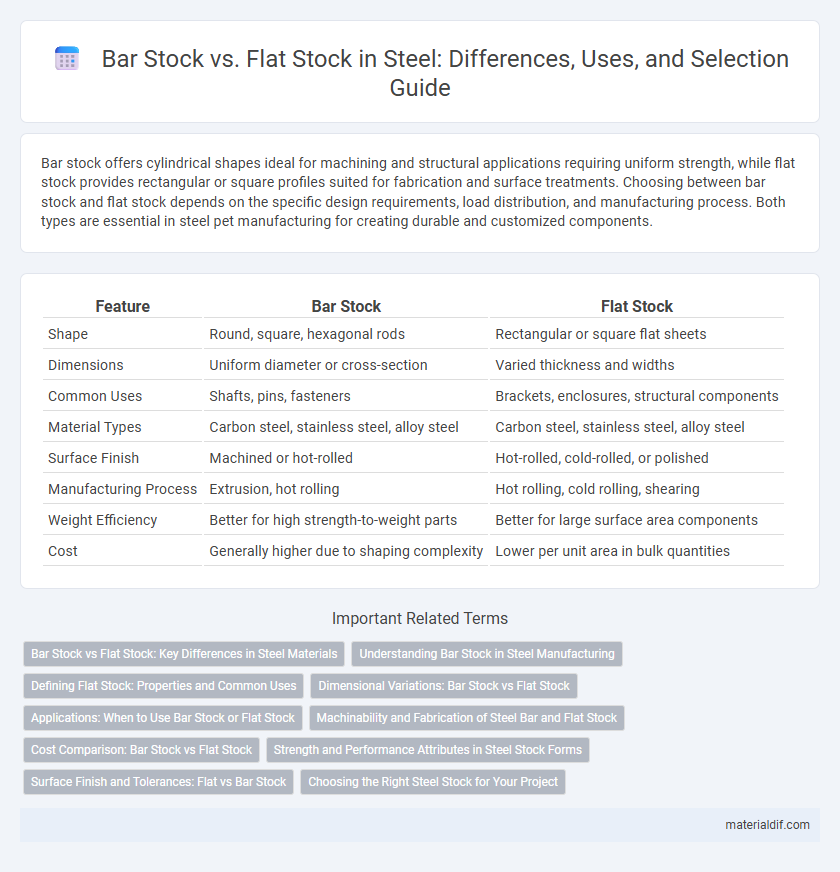

Table of Comparison

| Feature | Bar Stock | Flat Stock |

|---|---|---|

| Shape | Round, square, hexagonal rods | Rectangular or square flat sheets |

| Dimensions | Uniform diameter or cross-section | Varied thickness and widths |

| Common Uses | Shafts, pins, fasteners | Brackets, enclosures, structural components |

| Material Types | Carbon steel, stainless steel, alloy steel | Carbon steel, stainless steel, alloy steel |

| Surface Finish | Machined or hot-rolled | Hot-rolled, cold-rolled, or polished |

| Manufacturing Process | Extrusion, hot rolling | Hot rolling, cold rolling, shearing |

| Weight Efficiency | Better for high strength-to-weight parts | Better for large surface area components |

| Cost | Generally higher due to shaping complexity | Lower per unit area in bulk quantities |

Bar Stock vs Flat Stock: Key Differences in Steel Materials

Bar stock and flat stock are two fundamental forms of steel materials with distinct shapes and applications. Bar stock is typically cylindrical or hexagonal, used in machining and manufacturing shafts, bolts, and fasteners, while flat stock is characterized by its rectangular, flat shape, ideal for fabrication, structural components, and metalworking projects. Understanding the differences between bar stock and flat stock helps in selecting the right steel type based on strength, machinability, and intended use in industrial applications.

Understanding Bar Stock in Steel Manufacturing

Bar stock in steel manufacturing refers to solid metal pieces with a consistent cross-sectional shape, typically round, square, or hexagonal, used as raw material for machining or fabrication. Unlike flat stock, which is sheet or plate steel with a flat surface, bar stock offers greater structural integrity and versatility for precision components. Understanding the specific dimensions, alloys, and mechanical properties of bar stock is crucial for optimizing strength, machinability, and application in automotive, construction, and industrial machinery sectors.

Defining Flat Stock: Properties and Common Uses

Flat stock steel features a rectangular cross-section with a consistent thickness and width, offering excellent surface finish and dimensional stability. Commonly crafted from carbon steel, stainless steel, or alloy steel, flat stock is widely used in manufacturing brackets, panels, machine parts, and structural applications. Its versatility and ease of machining make it ideal for custom fabricated components requiring flatness and precise dimensions.

Dimensional Variations: Bar Stock vs Flat Stock

Bar stock typically features uniform, round dimensions such as diameters ranging from 0.25 to 12 inches, ideal for machining precision parts. Flat stock, available in widths from 0.5 to 48 inches and thicknesses between 0.03 to 2 inches, provides versatile planar surfaces for applications like stamping and fabricating. Dimensional variability in bar stock is primarily radial, while flat stock emphasizes length, width, and thickness tolerances, affecting mechanical properties and manufacturing processes.

Applications: When to Use Bar Stock or Flat Stock

Bar stock is ideal for applications requiring round, square, or hexagonal cross-sections commonly used in machining, fabrication, and construction of shafts, pins, or fasteners. Flat stock suits applications needing uniform thickness and width, such as brackets, clamps, and ornamental metalwork typically found in automotive, aerospace, and structural frameworks. Choosing between bar stock and flat stock depends on the desired shape, mechanical properties, and specific design requirements of the steel component.

Machinability and Fabrication of Steel Bar and Flat Stock

Steel bar stock, typically round or hexagonal, offers enhanced machinability due to uniform cross-sections and consistent grain structure, making it ideal for precision turning and drilling. Flat stock, with its broad and thin profile, provides greater versatility in fabrication processes such as bending, welding, and stamping but may require additional preparation for machining accuracy. Both forms present distinct advantages depending on project requirements, balancing ease of machining against fabrication flexibility in steel manufacturing.

Cost Comparison: Bar Stock vs Flat Stock

Bar stock typically offers cost advantages due to higher material yields and reduced waste compared to flat stock, making it more efficient for machining processes. Flat stock, while often cheaper per unit weight, may incur additional expenses in fabrication and secondary operations such as cutting or forming. Evaluating total project costs requires considering not only raw material prices but also machining time, scrap rates, and production volume.

Strength and Performance Attributes in Steel Stock Forms

Bar stock steel typically offers superior strength and durability due to its uniform cross-section and ability to withstand high stress applications. Flat stock steel provides enhanced surface area and flexibility, making it ideal for projects requiring broader load distribution and precise performance. Understanding the mechanical properties such as tensile strength, yield strength, and impact resistance is crucial when selecting between bar stock and flat stock for structural or manufacturing purposes.

Surface Finish and Tolerances: Flat vs Bar Stock

Bar stock typically offers a smoother surface finish and tighter dimensional tolerances compared to flat stock, making it ideal for precision machining applications. Flat stock often has a rougher finish and greater thickness variability due to its manufacturing process, influencing its suitability for structural or less dimensionally critical uses. Choosing between bar and flat stock depends on the required surface quality and tolerance specifications for the steel component.

Choosing the Right Steel Stock for Your Project

Bar stock and flat stock serve distinct purposes based on their shapes and structural applications in steel projects. Choosing the right steel stock requires evaluating factors such as load-bearing requirements, machinability, and the specific geometry needed; bar stock is ideal for round or square cross-sections and mechanical components, while flat stock suits applications needing flat, wide surfaces like brackets or panels. Understanding steel grades and their mechanical properties ensures optimal performance and cost efficiency in manufacturing.

Bar Stock vs Flat Stock Infographic

materialdif.com

materialdif.com