High-speed steel offers exceptional hardness and heat resistance, making it ideal for cutting tools and machining applications where durability at elevated temperatures is crucial. Spring steel, in contrast, provides superior elasticity and fatigue resistance, commonly used in manufacturing springs and flexible components that require consistent performance under repeated stress. Both steels serve distinct functions: high-speed steel excels in precision toolmaking, while spring steel is preferred for mechanical flexibility and resilience.

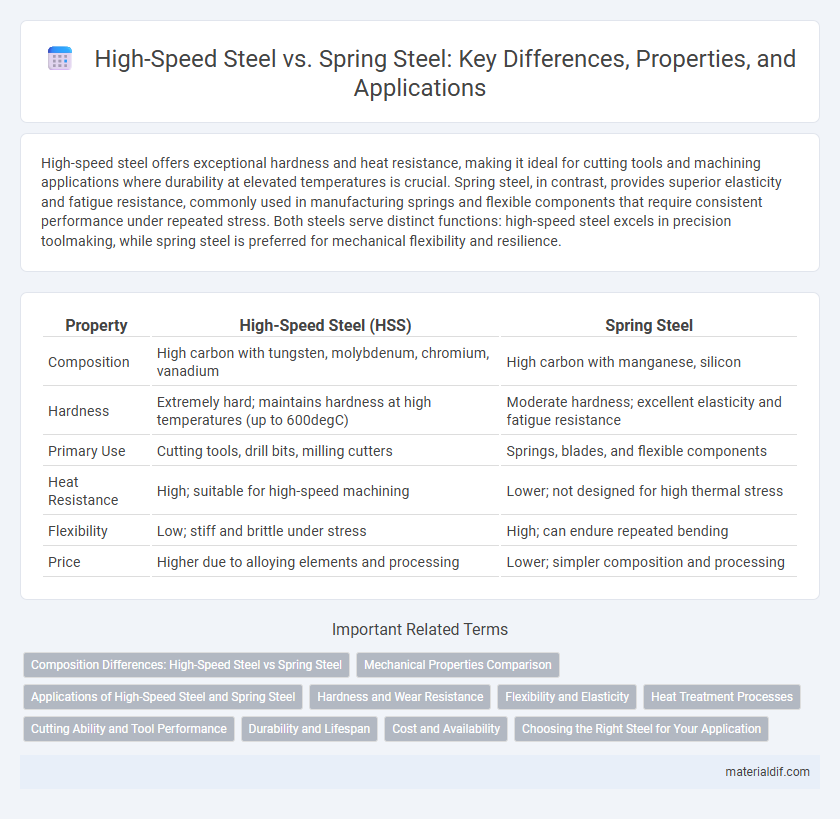

Table of Comparison

| Property | High-Speed Steel (HSS) | Spring Steel |

|---|---|---|

| Composition | High carbon with tungsten, molybdenum, chromium, vanadium | High carbon with manganese, silicon |

| Hardness | Extremely hard; maintains hardness at high temperatures (up to 600degC) | Moderate hardness; excellent elasticity and fatigue resistance |

| Primary Use | Cutting tools, drill bits, milling cutters | Springs, blades, and flexible components |

| Heat Resistance | High; suitable for high-speed machining | Lower; not designed for high thermal stress |

| Flexibility | Low; stiff and brittle under stress | High; can endure repeated bending |

| Price | Higher due to alloying elements and processing | Lower; simpler composition and processing |

Composition Differences: High-Speed Steel vs Spring Steel

High-speed steel (HSS) typically contains higher amounts of tungsten, molybdenum, and vanadium, which provide superior heat resistance and hardness compared to spring steel. Spring steel primarily consists of carbon and manganese with lower alloying elements, optimizing it for flexibility and tensile strength rather than cutting performance. The distinct composition differences directly influence their applications, with HSS used in cutting tools and spring steel in mechanical springs and high-stress components.

Mechanical Properties Comparison

High-speed steel offers superior hardness and wear resistance due to its high carbon and alloy content, making it ideal for cutting tools operating at elevated temperatures. Spring steel, characterized by its excellent elasticity and tensile strength, provides exceptional fatigue resistance, enabling it to return to its original shape after repeated stress. The mechanical properties of high-speed steel emphasize hardness and thermal stability, while spring steel focuses on flexibility and durability under cyclic loading.

Applications of High-Speed Steel and Spring Steel

High-speed steel (HSS) is primarily used in cutting tools such as drill bits, saw blades, and milling cutters due to its ability to retain hardness at elevated temperatures, enhancing performance in high-speed machining. Spring steel is widely applied in manufacturing springs, clips, and fasteners, valued for its exceptional elasticity and fatigue resistance, ensuring durability under repeated stress. Both steels serve specialized roles across automotive, aerospace, and manufacturing industries where their unique mechanical properties optimize functionality.

Hardness and Wear Resistance

High-speed steel exhibits superior hardness, typically ranging from 62 to 65 HRC, due to its high carbon and alloy content, making it ideal for cutting tools. Spring steel, while offering excellent flexibility and fatigue resistance, generally has lower hardness around 50 to 60 HRC, providing moderate wear resistance suited for mechanical springs. The enhanced wear resistance of high-speed steel results from its ability to maintain hardness at elevated temperatures, outperforming spring steel in abrasion and edge retention.

Flexibility and Elasticity

High-speed steel (HSS) offers exceptional hardness and wear resistance, making it ideal for cutting tools but has limited flexibility compared to spring steel. Spring steel is specifically designed for high elasticity and flexibility, allowing it to return to its original shape after significant bending or twisting. The superior elastic properties of spring steel make it preferable for applications requiring repeated deformation without permanent distortion.

Heat Treatment Processes

High-speed steel undergoes a complex heat treatment process involving hardening at temperatures between 1,200degC to 1,250degC, followed by rapid quenching and multiple tempering cycles to achieve superior hardness and wear resistance. Spring steel is typically heat treated through austenitizing at approximately 800degC to 900degC, then quenched and tempered to optimize its elasticity and toughness for dynamic load applications. The contrasting heat treatment parameters directly influence the microstructure, with high-speed steel forming stable carbides for cutting performance while spring steel develops tempered martensite for resilience.

Cutting Ability and Tool Performance

High-speed steel (HSS) offers superior cutting ability due to its high hardness and heat resistance, enabling it to maintain a sharp edge at elevated temperatures, making it ideal for cutting tools and drill bits. Spring steel, while known for its excellent elasticity and fatigue resistance, generally exhibits lower cutting performance and is better suited for applications requiring flexibility and strength rather than precision cutting. Tool performance in HSS surpasses spring steel in scenarios involving high-speed machining and heavy-duty cutting operations.

Durability and Lifespan

High-speed steel offers exceptional durability due to its superior hardness and resistance to wear at elevated temperatures, making it ideal for cutting tools that require prolonged performance under stress. Spring steel, while highly flexible and resilient, exhibits a shorter lifespan when subjected to constant friction and heat compared to high-speed steel. The enhanced lifespan of high-speed steel is attributed to its alloy composition, including elements like tungsten, molybdenum, and chromium, which contribute to improved toughness and thermal stability.

Cost and Availability

High-speed steel (HSS) generally commands a higher price due to its superior alloy content and advanced manufacturing processes, making it less readily available in bulk compared to spring steel. Spring steel is more widely accessible and cost-effective, commonly used in applications requiring flexibility and resilience without the premium expense of HSS. Cost efficiency and availability of spring steel make it a preferred choice for large-scale production, while HSS is reserved for specialized cutting tools requiring enhanced durability and heat resistance.

Choosing the Right Steel for Your Application

High-speed steel offers superior hardness and heat resistance, making it ideal for cutting tools and drilling applications that require maintaining sharpness at elevated temperatures. Spring steel provides excellent elasticity and fatigue resistance, perfect for applications involving repeated stress such as springs, clips, and flexible components. Selecting the right steel depends on factors like mechanical stress, temperature conditions, and wear resistance needed for your specific industrial or manufacturing application.

High-Speed Steel vs Spring Steel Infographic

materialdif.com

materialdif.com