Weathering steel develops a protective rust layer that enhances corrosion resistance, reducing maintenance costs compared to standard structural steel. Unlike traditional steel, weathering steel eliminates the need for painting, making it ideal for outdoor applications exposed to varying weather conditions. Standard structural steel requires coatings or treatments to prevent rust and deterioration, which can increase long-term expenses and downtime.

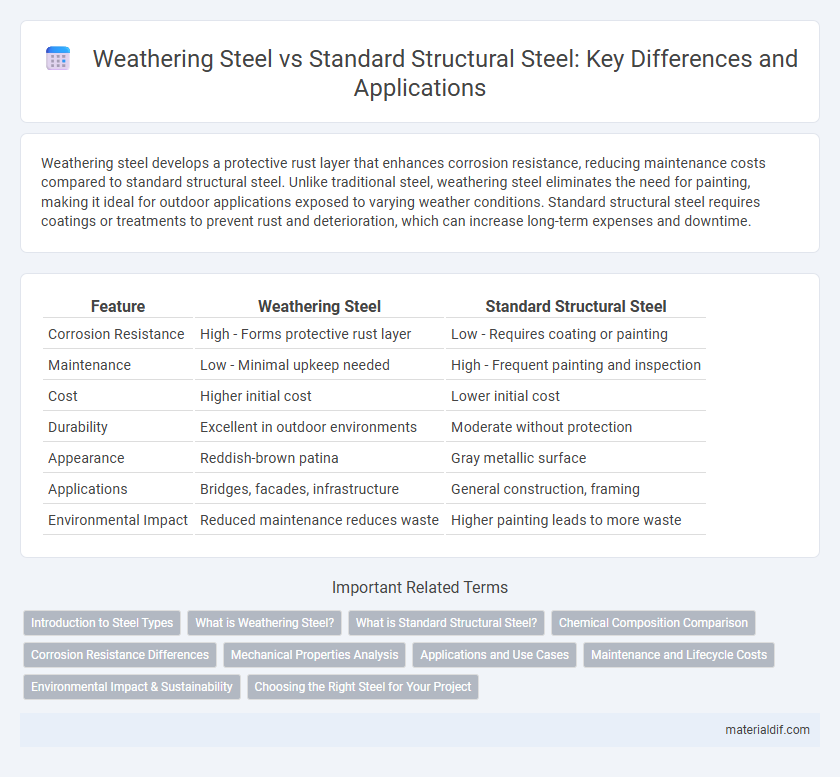

Table of Comparison

| Feature | Weathering Steel | Standard Structural Steel |

|---|---|---|

| Corrosion Resistance | High - Forms protective rust layer | Low - Requires coating or painting |

| Maintenance | Low - Minimal upkeep needed | High - Frequent painting and inspection |

| Cost | Higher initial cost | Lower initial cost |

| Durability | Excellent in outdoor environments | Moderate without protection |

| Appearance | Reddish-brown patina | Gray metallic surface |

| Applications | Bridges, facades, infrastructure | General construction, framing |

| Environmental Impact | Reduced maintenance reduces waste | Higher painting leads to more waste |

Introduction to Steel Types

Weathering steel, also known as COR-TEN steel, is engineered to form a stable rust-like appearance after exposure to weather, reducing the need for painting and maintenance. Standard structural steel, typically made from carbon and alloy elements, requires protective coatings to prevent corrosion over time. Both types are widely used in construction, but weathering steel offers enhanced durability in outdoor environments by developing a protective oxide layer.

What is Weathering Steel?

Weathering steel, also known as corten steel, is a high-strength alloy designed to form a stable rust-like appearance when exposed to weather, which eliminates the need for painting and reduces maintenance costs. Its chemical composition includes copper, chromium, and nickel, which enhance corrosion resistance by forming a protective oxide layer that prevents deeper rust penetration. This makes weathering steel ideal for outdoor structures such as bridges, sculptures, and building facades where long-term durability and reduced upkeep are critical.

What is Standard Structural Steel?

Standard structural steel, typically composed of carbon steel, is widely used in construction due to its high strength and versatility. It lacks the corrosion-resistant properties found in weathering steel, requiring protective coatings like paint or galvanization to prevent rust. Common grades such as ASTM A36 provide reliable performance in various structural applications but necessitate ongoing maintenance to ensure durability.

Chemical Composition Comparison

Weathering steel contains copper, chromium, nickel, and phosphorus, which enhance its corrosion resistance by forming a protective rust patina, unlike standard structural steel that primarily consists of iron with carbon and minor amounts of manganese and silicon. The increased presence of alloying elements in weathering steel creates a stable oxide layer, reducing the need for painting and maintenance in outdoor environments. Standard structural steel's simpler chemical composition focuses on strength and weldability but lacks the corrosion-resistant properties offered by weathering steel's specialized alloys.

Corrosion Resistance Differences

Weathering steel forms a stable, rust-like patina on its surface that significantly enhances its corrosion resistance compared to standard structural steel, which requires protective coatings to prevent rust. This patina acts as a barrier that minimizes further corrosion by sealing the metal from moisture and oxygen exposure. Standard structural steel, lacking this self-protective layer, is more susceptible to rust and degradation, especially in harsh weather conditions or industrial environments.

Mechanical Properties Analysis

Weathering steel exhibits enhanced corrosion resistance due to its alloy composition, leading to improved durability and reduced maintenance compared to standard structural steel. Mechanical properties such as tensile strength and yield strength in weathering steel are often comparable or slightly superior to those of conventional carbon structural steels, making it suitable for load-bearing applications. The fatigue resistance and impact toughness of weathering steel also remain consistent with or better than standard structural steel, ensuring reliability in dynamic and harsh environmental conditions.

Applications and Use Cases

Weathering steel is widely used in outdoor structures such as bridges, facades, and sculptures due to its corrosion-resistant properties that develop a protective rust patina, reducing maintenance needs. Standard structural steel remains popular in construction projects requiring welding, painting, and controlled environments, such as building frames, machinery, and industrial equipment. Weathering steel suits environments with alternating wet and dry conditions, while standard structural steel excels in indoor or coated applications where precise fabrication and long-term strength are critical.

Maintenance and Lifecycle Costs

Weathering steel significantly reduces maintenance costs due to its corrosion-resistant oxide layer, eliminating the need for painting or regular treatments unlike standard structural steel which requires frequent upkeep to prevent rust. This protective patina extends the lifecycle of weathering steel structures, resulting in lower total ownership costs over time. Standard structural steel, while initially cheaper, incurs higher expenses related to maintenance and corrosion control throughout its service life.

Environmental Impact & Sustainability

Weathering steel significantly reduces environmental impact by eliminating the need for painting or protective coatings, which lowers volatile organic compound (VOC) emissions and maintenance-related waste. Its corrosion-resistant properties extend the lifespan of structures, minimizing resource consumption and reducing the frequency of steel replacement compared to standard structural steel. This durability and reduced maintenance contribute to enhanced sustainability in construction projects by conserving raw materials and lowering carbon footprints.

Choosing the Right Steel for Your Project

Weathering steel, known for its corrosion-resistant properties due to a protective oxide layer, offers long-term durability and reduced maintenance costs compared to standard structural steel. Projects exposed to harsh environmental conditions, such as bridges and outdoor sculptures, benefit from weathering steel's ability to withstand rust without compromising structural integrity. Standard structural steel remains a cost-effective choice for indoor or less corrosive environments where protective coatings can be applied as needed.

Weathering Steel vs Standard Structural Steel Infographic

materialdif.com

materialdif.com