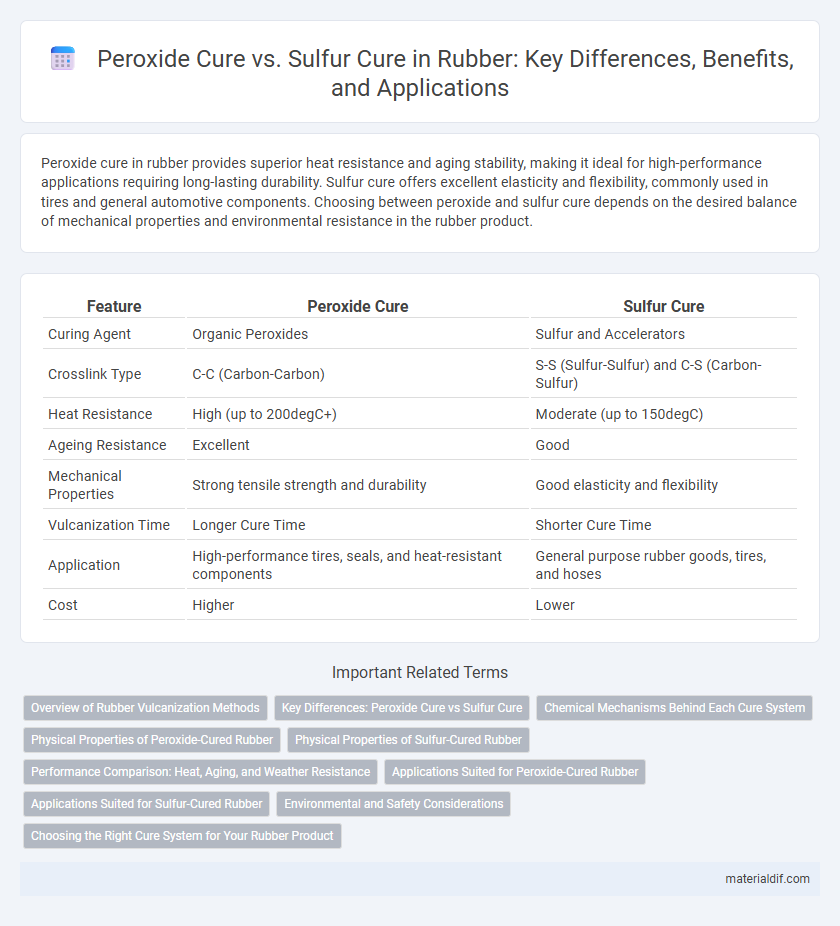

Peroxide cure in rubber provides superior heat resistance and aging stability, making it ideal for high-performance applications requiring long-lasting durability. Sulfur cure offers excellent elasticity and flexibility, commonly used in tires and general automotive components. Choosing between peroxide and sulfur cure depends on the desired balance of mechanical properties and environmental resistance in the rubber product.

Table of Comparison

| Feature | Peroxide Cure | Sulfur Cure |

|---|---|---|

| Curing Agent | Organic Peroxides | Sulfur and Accelerators |

| Crosslink Type | C-C (Carbon-Carbon) | S-S (Sulfur-Sulfur) and C-S (Carbon-Sulfur) |

| Heat Resistance | High (up to 200degC+) | Moderate (up to 150degC) |

| Ageing Resistance | Excellent | Good |

| Mechanical Properties | Strong tensile strength and durability | Good elasticity and flexibility |

| Vulcanization Time | Longer Cure Time | Shorter Cure Time |

| Application | High-performance tires, seals, and heat-resistant components | General purpose rubber goods, tires, and hoses |

| Cost | Higher | Lower |

Overview of Rubber Vulcanization Methods

Rubber vulcanization methods primarily include peroxide cure and sulfur cure, each offering distinct chemical crosslinking mechanisms that enhance polymer stability. Peroxide cure forms carbon-carbon bonds, providing superior heat and chemical resistance, ideal for specialty elastomers and high-temperature applications. Sulfur cure introduces sulfur crosslinks, delivering excellent elasticity and tensile strength, commonly used in natural rubber and general-purpose products.

Key Differences: Peroxide Cure vs Sulfur Cure

Peroxide cure in rubber vulcanization offers superior heat and aging resistance by creating carbon-carbon crosslinks, while sulfur cure forms sulfur-based crosslinks that provide better elasticity and tensile strength. Peroxide-cured rubber exhibits higher thermal stability, making it ideal for high-temperature applications, whereas sulfur-cured rubber is preferred for general-purpose products requiring flexibility. The choice between peroxide cure and sulfur cure depends on performance requirements, with peroxide curing favored for chemical resistance and durability, and sulfur curing for improved processability and mechanical properties.

Chemical Mechanisms Behind Each Cure System

Peroxide cure systems rely on free radical generation to crosslink polymer chains through carbon-carbon bonds, resulting in superior heat resistance and weathering properties. Sulfur cure systems form crosslinks via sulfur atoms creating polysulfidic bonds, which enhance elasticity and tensile strength but may reduce thermal stability. The choice between peroxide and sulfur curing depends on the desired balance between mechanical performance and thermal durability in rubber products.

Physical Properties of Peroxide-Cured Rubber

Peroxide-cured rubber exhibits superior heat resistance and enhanced mechanical strength compared to sulfur-cured rubber, making it ideal for high-temperature applications. This curing method produces a carbon-carbon crosslink structure, resulting in improved aging stability and reduced compression set. Peroxide-cured elastomers also demonstrate excellent chemical resistance, particularly against oils and solvents, which extends the service life of rubber components in harsh environments.

Physical Properties of Sulfur-Cured Rubber

Sulfur-cured rubber exhibits superior tensile strength, elasticity, and abrasion resistance compared to peroxide-cured rubber, making it ideal for dynamic applications like tires and conveyor belts. The vulcanization process forms polysulfidic cross-links that enhance flexibility and resilience under repeated stress. This curing method also improves aging resistance and elongation at break, contributing to the material's durability in harsh environmental conditions.

Performance Comparison: Heat, Aging, and Weather Resistance

Peroxide-cured rubber exhibits superior heat resistance, maintaining mechanical properties at elevated temperatures above 150degC, compared to sulfur-cured rubber which tends to degrade faster under prolonged heat exposure. In terms of aging resistance, peroxide curing provides enhanced retention of tensile strength and elasticity after extended thermal and oxidative aging, making it more durable for long-term applications. Sulfur-cured rubber generally offers better flexibility and resilience but shows diminished weather resistance, especially under UV exposure and ozone attack, where peroxide cure systems excel.

Applications Suited for Peroxide-Cured Rubber

Peroxide-cured rubber exhibits superior heat resistance, aging stability, and chemical resistance, making it ideal for high-performance applications such as automotive hoses, seals, and gaskets exposed to extreme temperatures and aggressive chemicals. Its crosslinking mechanism creates carbon-carbon bonds, which enhance tensile strength and compression set resistance, particularly suited for specialty elastomers like EPDM and silicone. This curing method is preferred in industries requiring materials with minimal bloom, low odor, and consistent physical properties over prolonged service life.

Applications Suited for Sulfur-Cured Rubber

Sulfur-cured rubber is extensively used in automotive tires, conveyor belts, and footwear due to its excellent elasticity and abrasion resistance. This curing method enhances the mechanical properties and chemical stability, making it ideal for products that undergo dynamic stress and harsh environmental conditions. The enhanced durability of sulfur-cured rubber ensures a longer service life in industrial and consumer goods.

Environmental and Safety Considerations

Peroxide cures produce fewer hazardous emissions such as sulfur oxides and nitrosamines, making them a safer option for both workers and the environment compared to sulfur cures. Sulfur curing involves volatile organic compounds (VOCs) and potentially carcinogenic byproducts, raising concerns about air quality and occupational health. Peroxide cure systems also reduce the risk of allergic reactions and environmental contamination due to their cleaner cross-linking process.

Choosing the Right Cure System for Your Rubber Product

Peroxide cure systems provide superior heat resistance and aging stability, making them ideal for rubber products exposed to high temperatures or harsh environments. Sulfur cure systems, favored for their cost-effectiveness and excellent mechanical properties, are preferred in applications requiring flexibility and elasticity, such as tires and seals. Selecting the right cure system depends on the specific performance requirements, including thermal stability, durability, and application conditions of the rubber product.

Peroxide Cure vs Sulfur Cure Infographic

materialdif.com

materialdif.com