Rubber compounding involves blending pure rubber with additives like fillers, curing agents, and plasticizers to enhance properties such as strength, flexibility, and durability, tailored for specific applications. Pure rubber, on the other hand, lacks these modifications and offers limited performance characteristics, making it less suitable for demanding industrial uses. Optimizing rubber compounds improves resistance to heat, abrasion, and chemicals, ensuring better product lifespan compared to unmodified pure rubber.

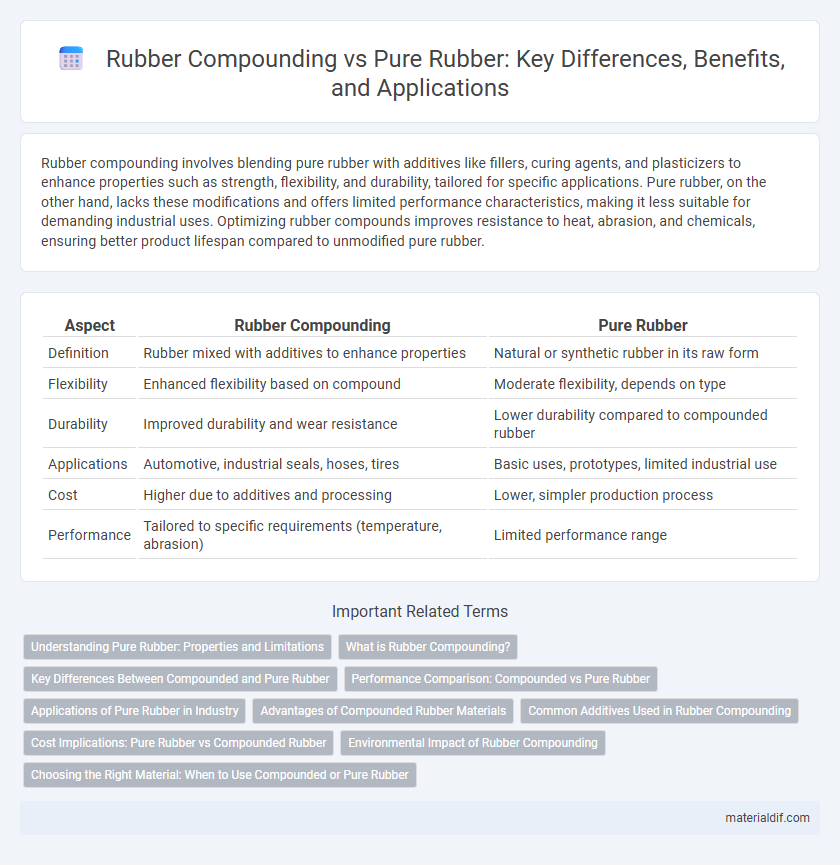

Table of Comparison

| Aspect | Rubber Compounding | Pure Rubber |

|---|---|---|

| Definition | Rubber mixed with additives to enhance properties | Natural or synthetic rubber in its raw form |

| Flexibility | Enhanced flexibility based on compound | Moderate flexibility, depends on type |

| Durability | Improved durability and wear resistance | Lower durability compared to compounded rubber |

| Applications | Automotive, industrial seals, hoses, tires | Basic uses, prototypes, limited industrial use |

| Cost | Higher due to additives and processing | Lower, simpler production process |

| Performance | Tailored to specific requirements (temperature, abrasion) | Limited performance range |

Understanding Pure Rubber: Properties and Limitations

Pure rubber exhibits excellent elasticity, resilience, and flexibility but lacks sufficient mechanical strength and durability for most practical applications. Its inherent low resistance to abrasion, heat, and environmental factors limits its standalone use in industrial products. Rubber compounding enhances pure rubber by incorporating fillers, plasticizers, and curing agents that improve performance properties such as tensile strength, wear resistance, and aging stability.

What is Rubber Compounding?

Rubber compounding involves blending raw rubber with various additives such as fillers, plasticizers, accelerators, and vulcanizing agents to enhance physical properties and tailor performance for specific applications. Unlike pure rubber, compounded rubber offers improved durability, elasticity, resistance to heat, chemicals, and abrasion, making it essential in automotive tires, industrial gaskets, and seals. The precise formulation of rubber compounds directly influences product quality, manufacturing efficiency, and cost-effectiveness in the rubber industry.

Key Differences Between Compounded and Pure Rubber

Rubber compounding involves blending natural or synthetic rubber with fillers, plasticizers, curing agents, and other additives to enhance performance characteristics like durability, elasticity, and resistance to heat and chemicals, whereas pure rubber consists of unmodified polymer chains with limited mechanical properties. Compounded rubber exhibits improved processing qualities and tailored functionalities suited for specific industrial applications, unlike pure rubber which typically lacks such versatility and strength. The key differences lie in the enhanced physical properties, extended lifespan, and better performance consistency found in compounded rubber compared to the raw, unprocessed nature of pure rubber.

Performance Comparison: Compounded vs Pure Rubber

Compounded rubber significantly outperforms pure rubber in durability, elasticity, and resistance to environmental factors such as heat, ozone, and chemicals. The addition of fillers, plasticizers, and curing agents during the compounding process enhances mechanical properties and tailor-makes rubber for specific industrial applications. Pure rubber lacks these additives, resulting in lower tensile strength and reduced wear resistance compared to compounded rubber formulations.

Applications of Pure Rubber in Industry

Pure rubber offers exceptional elasticity and resilience, making it ideal for applications requiring high flexibility and durability such as medical gloves, sealing elements, and vibration isolation pads. Its superior chemical resistance and biocompatibility enable use in pharmaceutical and food-processing industries where contamination prevention is critical. Unlike compounded rubber, pure rubber's consistent molecular structure ensures predictable performance in sensitive industrial components.

Advantages of Compounded Rubber Materials

Compounded rubber materials enhance the physical properties of pure rubber by incorporating additives such as fillers, accelerators, and curing agents, resulting in improved strength, durability, and resistance to abrasion and chemicals. These tailored formulations enable customization for specific applications, including automotive parts, industrial seals, and footwear, where enhanced performance under stress and environmental exposure is critical. Compared to pure rubber, compounded rubbers offer superior elasticity, aging resistance, and processing efficiency, making them ideal for demanding operational conditions.

Common Additives Used in Rubber Compounding

Rubber compounding involves the addition of various additives such as carbon black, sulfur, accelerators, plasticizers, and fillers to enhance the physical and chemical properties of pure rubber, improving durability, elasticity, and resistance to abrasion. Carbon black increases tensile strength and wear resistance, while sulfur facilitates vulcanization, creating cross-links between polymer chains. Plasticizers improve flexibility, and fillers like silica enhance mechanical properties and reduce production costs, making compounded rubber suitable for diverse industrial applications.

Cost Implications: Pure Rubber vs Compounded Rubber

Pure rubber typically incurs higher costs due to its limited processing versatility and lack of performance enhancements, resulting in increased material waste and lower durability. Rubber compounding introduces additives such as fillers, plasticizers, and curing agents, significantly reducing overall expenses by improving mechanical properties and extending product lifespan. Cost efficiency in rubber compounding stems from optimizing raw material usage and enhancing manufacturing throughput, leading to substantial savings compared to pure rubber applications.

Environmental Impact of Rubber Compounding

Rubber compounding involves blending natural or synthetic rubber with additives such as fillers, plasticizers, and curing agents, which enhances material properties but increases environmental footprints through chemical usage and waste generation. Pure rubber, while more biodegradable, lacks the durability and performance given by compounded rubber, often leading to shorter product lifespan and higher replacement rates. The environmental impact of rubber compounding is significant due to emissions from processing, potential release of hazardous substances, and challenges in recycling compounded rubber products.

Choosing the Right Material: When to Use Compounded or Pure Rubber

Compounded rubber combines base polymers with additives such as fillers, plasticizers, and curing agents to enhance properties like durability, flexibility, and resistance to heat or chemicals, making it ideal for demanding industrial applications. Pure rubber offers superior elasticity and natural resilience, suitable for products requiring minimal processing or enhanced biocompatibility, like medical devices and seals. Selecting compounded rubber optimizes performance in harsh environments, whereas pure rubber is preferred when chemical purity and natural properties are critical.

Rubber Compounding vs Pure Rubber Infographic

materialdif.com

materialdif.com