Vulcanized rubber undergoes a chemical process that improves its strength, elasticity, and durability by forming cross-links between polymer chains, making it more resistant to heat, abrasion, and deformation compared to non-vulcanized rubber. Non-vulcanized rubber remains soft and sticky, with limited mechanical properties and poor resistance to environmental factors, which restricts its applications. The enhanced performance of vulcanized rubber makes it ideal for tires, seals, and industrial products requiring long-lasting flexibility and resilience.

Table of Comparison

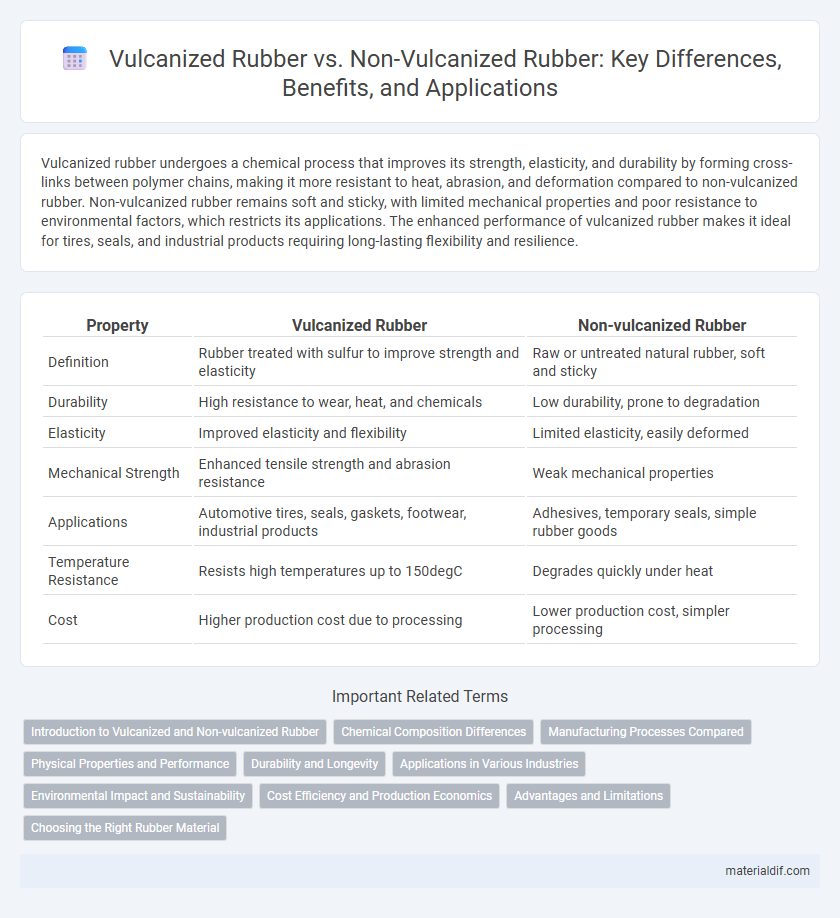

| Property | Vulcanized Rubber | Non-vulcanized Rubber |

|---|---|---|

| Definition | Rubber treated with sulfur to improve strength and elasticity | Raw or untreated natural rubber, soft and sticky |

| Durability | High resistance to wear, heat, and chemicals | Low durability, prone to degradation |

| Elasticity | Improved elasticity and flexibility | Limited elasticity, easily deformed |

| Mechanical Strength | Enhanced tensile strength and abrasion resistance | Weak mechanical properties |

| Applications | Automotive tires, seals, gaskets, footwear, industrial products | Adhesives, temporary seals, simple rubber goods |

| Temperature Resistance | Resists high temperatures up to 150degC | Degrades quickly under heat |

| Cost | Higher production cost due to processing | Lower production cost, simpler processing |

Introduction to Vulcanized and Non-vulcanized Rubber

Vulcanized rubber is chemically treated with sulfur or other curatives to enhance elasticity, strength, and durability, making it ideal for automotive tires, industrial products, and footwear. Non-vulcanized rubber, often referred to as raw or natural rubber, retains its original sticky and soft properties, limiting its use to applications where flexibility and easy molding are prioritized but mechanical strength is less critical. The key difference lies in the cross-linking of polymer chains in vulcanized rubber, providing superior performance characteristics compared to the more pliable and less resilient non-vulcanized form.

Chemical Composition Differences

Vulcanized rubber undergoes a chemical process where sulfur atoms create cross-links between polymer chains, significantly enhancing elasticity, strength, and durability. Non-vulcanized rubber consists primarily of long polymer chains of isoprene with minimal cross-linking, resulting in softer, more adhesive, and less resilient material. The chemical composition of vulcanized rubber includes sulfur cross-links and often accelerators or additives, whereas non-vulcanized rubber remains mostly natural polyisoprene without such modifications.

Manufacturing Processes Compared

Vulcanized rubber undergoes a chemical process involving sulfur and heat, which creates cross-links between polymer chains, enhancing elasticity, strength, and durability. Non-vulcanized rubber retains its original polymer structure, resulting in material that is more flexible but less resistant to wear, heat, and chemical exposure. The manufacturing of vulcanized rubber typically includes mixing raw rubber with sulfur and accelerators, followed by controlled heating, while non-vulcanized rubber manufacturing involves simple mixing and shaping without the heat-induced cross-linking step.

Physical Properties and Performance

Vulcanized rubber exhibits enhanced physical properties such as increased elasticity, tensile strength, and resistance to abrasion compared to non-vulcanized rubber, which remains softer and less durable. The sulfur cross-linking in vulcanized rubber improves its thermal stability and resilience, making it suitable for demanding applications like tires and industrial seals. Non-vulcanized rubber tends to deform easily under stress and degrades faster when exposed to heat and chemicals.

Durability and Longevity

Vulcanized rubber exhibits superior durability and longevity compared to non-vulcanized rubber due to its cross-linked polymer structure, which enhances resistance to wear, heat, and chemical exposure. This cross-linking process significantly reduces brittleness and deformation, maintaining elasticity over extended periods under harsh conditions. Non-vulcanized rubber lacks this molecular reinforcement, resulting in faster degradation and limited lifespan when subjected to mechanical stress and environmental factors.

Applications in Various Industries

Vulcanized rubber exhibits enhanced durability, elasticity, and heat resistance, making it ideal for automotive tires, industrial belts, and medical devices where performance under stress is crucial. Non-vulcanized rubber, with its softer texture and lower strength, is commonly used in products like adhesives, sealants, and temporary molds where flexibility and easy processing are prioritized. The distinct physical properties of vulcanized versus non-vulcanized rubber determine their specific applications across industries including manufacturing, healthcare, and consumer goods.

Environmental Impact and Sustainability

Vulcanized rubber, due to its cross-linked molecular structure, is more durable and resistant to degradation, which complicates recycling and leads to longer environmental persistence compared to non-vulcanized rubber. Non-vulcanized rubber, while less durable, tends to be more biodegradable and easier to recycle, thereby offering a potentially lower environmental impact. Sustainable practices in rubber production increasingly favor non-vulcanized or alternative rubber materials to reduce ecological footprints and improve end-of-life management.

Cost Efficiency and Production Economics

Vulcanized rubber offers superior cost efficiency in large-scale production due to its enhanced durability and reduced material waste compared to non-vulcanized rubber. The thermal curing process, despite higher initial costs, results in longer-lasting products that lower replacement frequency and maintenance expenses. In contrast, non-vulcanized rubber has lower upfront costs but incurs higher overall production economics due to shorter lifespan and increased susceptibility to environmental degradation.

Advantages and Limitations

Vulcanized rubber offers enhanced durability, elasticity, and resistance to heat, chemicals, and abrasion compared to non-vulcanized rubber, making it ideal for automotive tires and industrial applications. Non-vulcanized rubber, while more flexible and easier to process, lacks the mechanical strength and longevity required for heavy-duty uses, limiting its effectiveness in high-stress environments. The vulcanization process improves overall performance but adds cost and complexity, whereas non-vulcanized rubber remains suitable for temporary or low-impact products.

Choosing the Right Rubber Material

Vulcanized rubber offers enhanced durability, elasticity, and resistance to heat and chemicals compared to non-vulcanized rubber, making it ideal for industrial applications that demand long-lasting performance. Non-vulcanized rubber remains softer and more flexible but lacks the mechanical strength and resilience of vulcanized variants, restricting its use to simpler, low-stress environments. Selecting the right rubber material depends on the specific requirements for tensile strength, flexibility, temperature tolerance, and exposure to environmental factors.

Vulcanized Rubber vs Non-vulcanized Rubber Infographic

materialdif.com

materialdif.com