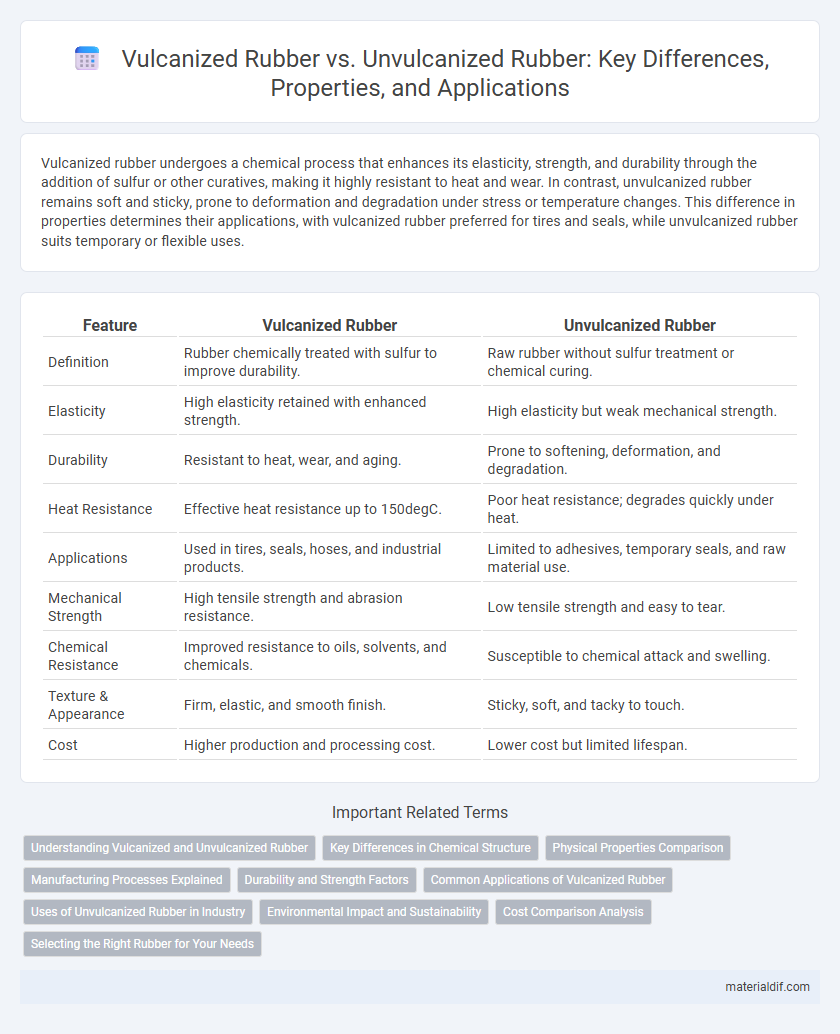

Vulcanized rubber undergoes a chemical process that enhances its elasticity, strength, and durability through the addition of sulfur or other curatives, making it highly resistant to heat and wear. In contrast, unvulcanized rubber remains soft and sticky, prone to deformation and degradation under stress or temperature changes. This difference in properties determines their applications, with vulcanized rubber preferred for tires and seals, while unvulcanized rubber suits temporary or flexible uses.

Table of Comparison

| Feature | Vulcanized Rubber | Unvulcanized Rubber |

|---|---|---|

| Definition | Rubber chemically treated with sulfur to improve durability. | Raw rubber without sulfur treatment or chemical curing. |

| Elasticity | High elasticity retained with enhanced strength. | High elasticity but weak mechanical strength. |

| Durability | Resistant to heat, wear, and aging. | Prone to softening, deformation, and degradation. |

| Heat Resistance | Effective heat resistance up to 150degC. | Poor heat resistance; degrades quickly under heat. |

| Applications | Used in tires, seals, hoses, and industrial products. | Limited to adhesives, temporary seals, and raw material use. |

| Mechanical Strength | High tensile strength and abrasion resistance. | Low tensile strength and easy to tear. |

| Chemical Resistance | Improved resistance to oils, solvents, and chemicals. | Susceptible to chemical attack and swelling. |

| Texture & Appearance | Firm, elastic, and smooth finish. | Sticky, soft, and tacky to touch. |

| Cost | Higher production and processing cost. | Lower cost but limited lifespan. |

Understanding Vulcanized and Unvulcanized Rubber

Vulcanized rubber undergoes a chemical process that introduces sulfur cross-links between polymer chains, significantly enhancing its strength, elasticity, and resistance to heat and wear compared to unvulcanized rubber. Unvulcanized rubber remains sticky, less durable, and prone to deformation under stress due to the absence of these cross-links. Understanding the structural differences highlights vulcanized rubber's superior performance in industrial applications such as tires, seals, and hoses.

Key Differences in Chemical Structure

Vulcanized rubber has a cross-linked molecular structure formed by sulfur atoms creating bridges between polymer chains, significantly enhancing its elasticity, strength, and thermal stability. In contrast, unvulcanized rubber consists of long, linear polymer chains without cross-links, making it softer, more tacky, and less resistant to heat and mechanical stress. This fundamental chemical difference results in vulcanized rubber being more durable and suitable for demanding applications compared to its unvulcanized counterpart.

Physical Properties Comparison

Vulcanized rubber exhibits enhanced physical properties such as increased tensile strength, elasticity, and resistance to abrasion compared to unvulcanized rubber, which remains soft and sticky with inferior mechanical stability. The vulcanization process introduces sulfur cross-links between polymer chains, significantly improving thermal stability, hardness, and durability under stress. Unvulcanized rubber displays poor resilience and deforms easily under mechanical forces, limiting its practical applications in demanding environments.

Manufacturing Processes Explained

Vulcanized rubber undergoes a chemical process where sulfur is added and the rubber is heated, creating cross-links between polymer chains that enhance elasticity, strength, and durability. In contrast, unvulcanized rubber remains in a plastic-like state without cross-linking, leading to lower mechanical properties and susceptibility to deformation. The vulcanization process is essential for producing rubber products like tires, seals, and hoses that require high performance and long service life.

Durability and Strength Factors

Vulcanized rubber exhibits significantly higher durability and strength compared to unvulcanized rubber due to the cross-linking of polymer chains through sulfur bonds, which enhances its resistance to abrasion, heat, and chemical exposure. Unvulcanized rubber remains softer and more pliable but lacks the structural integrity needed for prolonged mechanical stress, leading to faster wear and deformation. The vulcanization process improves tensile strength and elasticity, making vulcanized rubber ideal for industrial applications requiring long-lasting performance.

Common Applications of Vulcanized Rubber

Vulcanized rubber is widely used in automotive tires, conveyor belts, hoses, and shoe soles due to its enhanced durability, elasticity, and resistance to heat and chemicals. Its cross-linked molecular structure provides superior abrasion resistance and shape stability, making it ideal for heavy-duty industrial applications and everyday products requiring long-term performance. Unvulcanized rubber lacks these properties, limiting its use mostly to temporary seals or adhesives.

Uses of Unvulcanized Rubber in Industry

Unvulcanized rubber is primarily used in industries requiring flexible, malleable materials such as adhesives, sealants, and cushioning components. Its ability to be easily shaped and blended before curing makes it ideal for manufacturing custom gaskets, gloves, and temporary protective covers. This form of rubber is also important in producing latex products and as a raw material for further vulcanization in tire and rubber goods production.

Environmental Impact and Sustainability

Vulcanized rubber offers improved durability and resistance, reducing the frequency of replacement and waste generation compared to unvulcanized rubber, which tends to degrade faster and contributes more to landfill accumulation. The vulcanization process, however, often involves sulfur compounds and chemicals that may pose environmental hazards during manufacturing and disposal if not properly managed. Sustainable approaches emphasize recycling vulcanized rubber and developing bio-based alternatives to minimize ecological footprint and reliance on non-renewable resources.

Cost Comparison Analysis

Vulcanized rubber generally incurs higher production costs due to the additional chemical curing process involving sulfur, which enhances strength, elasticity, and durability. Unvulcanized rubber is cheaper upfront since it bypasses the vulcanization step but lacks the mechanical properties needed for long-term or high-stress applications. Cost efficiency analysis must consider the lifecycle value, where vulcanized rubber often provides better return on investment through improved performance and longevity despite its higher initial expense.

Selecting the Right Rubber for Your Needs

Vulcanized rubber offers enhanced durability, elasticity, and resistance to heat and chemicals, making it ideal for industrial applications and products requiring long-term performance. Unvulcanized rubber remains softer and more flexible but lacks the mechanical strength and weather resistance needed for heavy-duty use. Selecting the right rubber depends on the specific requirements of your project, balancing flexibility and cost against durability and resilience.

Vulcanized Rubber vs Unvulcanized Rubber Infographic

materialdif.com

materialdif.com