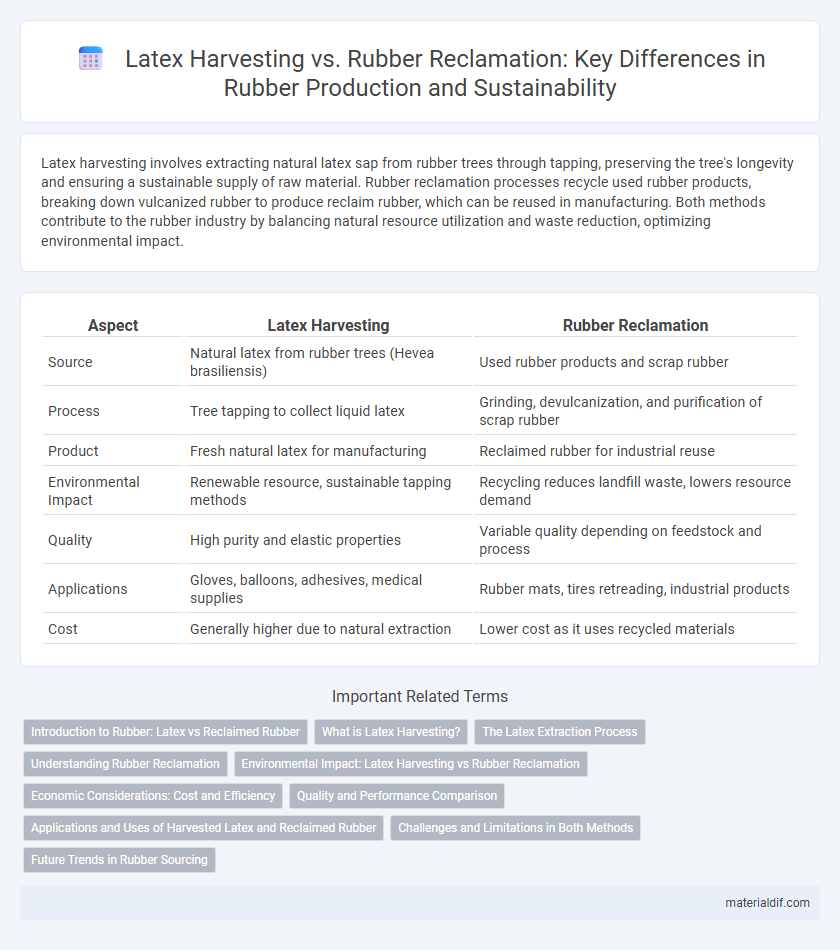

Latex harvesting involves extracting natural latex sap from rubber trees through tapping, preserving the tree's longevity and ensuring a sustainable supply of raw material. Rubber reclamation processes recycle used rubber products, breaking down vulcanized rubber to produce reclaim rubber, which can be reused in manufacturing. Both methods contribute to the rubber industry by balancing natural resource utilization and waste reduction, optimizing environmental impact.

Table of Comparison

| Aspect | Latex Harvesting | Rubber Reclamation |

|---|---|---|

| Source | Natural latex from rubber trees (Hevea brasiliensis) | Used rubber products and scrap rubber |

| Process | Tree tapping to collect liquid latex | Grinding, devulcanization, and purification of scrap rubber |

| Product | Fresh natural latex for manufacturing | Reclaimed rubber for industrial reuse |

| Environmental Impact | Renewable resource, sustainable tapping methods | Recycling reduces landfill waste, lowers resource demand |

| Quality | High purity and elastic properties | Variable quality depending on feedstock and process |

| Applications | Gloves, balloons, adhesives, medical supplies | Rubber mats, tires retreading, industrial products |

| Cost | Generally higher due to natural extraction | Lower cost as it uses recycled materials |

Introduction to Rubber: Latex vs Reclaimed Rubber

Latex harvesting involves extracting natural latex directly from rubber trees (Hevea brasiliensis), which serves as the primary raw material for producing high-quality natural rubber with superior elasticity and tensile strength. Reclaimed rubber, on the other hand, derives from recycled waste rubber products through chemical or mechanical processes, offering cost-effective material for applications with lower performance requirements. Understanding the differences between natural latex and reclaimed rubber is essential for selecting appropriate materials in manufacturing, balancing quality, sustainability, and economic factors.

What is Latex Harvesting?

Latex harvesting is the process of extracting natural latex sap from rubber trees through controlled tapping methods, ensuring the tree's health and sustained yield. This technique involves making precise incisions on the bark to collect the latex sap, which is then processed into raw rubber. Effective latex harvesting increases productivity and quality in the rubber industry compared to rubber reclamation, which involves recycling used rubber products.

The Latex Extraction Process

The latex extraction process involves tapping Hevea brasiliensis trees to collect fresh latex, which is then filtered and coagulated to produce natural rubber sheets. Latex harvesting requires precise cuts on the bark to ensure a continuous flow of latex without damaging the tree, while rubber reclamation recovers rubber from used or waste materials through chemical and mechanical treatments. Efficient latex extraction maximizes yield and preserves tree health, contrasting with rubber reclamation that emphasizes recycling and sustainability in rubber production.

Understanding Rubber Reclamation

Rubber reclamation involves processing used or scrap rubber materials to restore their physical properties for reuse, reducing environmental waste and reliance on natural latex harvesting. This process includes devulcanization techniques that break sulfur bonds, enabling recycled rubber to be incorporated into new products with comparable performance. Understanding rubber reclamation highlights its economic and ecological benefits compared to traditional latex harvesting, which solely depends on extracting fresh latex from rubber trees.

Environmental Impact: Latex Harvesting vs Rubber Reclamation

Latex harvesting involves tapping rubber trees to collect natural latex, which is renewable and minimally invasive, preserving biodiversity and reducing deforestation. Rubber reclamation reprocesses used rubber products, significantly reducing landfill waste and lowering the demand for virgin rubber, thus minimizing environmental pollution. Both methods contribute to sustainability, but latex harvesting supports ecosystem health while rubber reclamation addresses waste management challenges.

Economic Considerations: Cost and Efficiency

Latex harvesting involves lower initial investment with steady income from natural rubber extraction, benefiting smallholder farmers economically through sustainable tapping techniques. Rubber reclamation requires significant capital for processing used rubber products but offers cost savings by reducing raw material demand and supporting circular economy models. Efficiency in latex harvesting depends on tree health and tapping frequency, while reclamation efficiency hinges on advanced technology and scale of operation.

Quality and Performance Comparison

Latex harvesting produces high-quality natural rubber with superior elasticity and strength due to minimal processing, preserving molecular chains and fibril structures. In contrast, rubber reclamation involves recycling scrap rubber, resulting in reduced tensile strength and elasticity caused by partial degradation and contamination. Performance-wise, harvested latex excels in applications requiring durability and flexibility, while reclaimed rubber suits less demanding uses where cost-efficiency outweighs material purity.

Applications and Uses of Harvested Latex and Reclaimed Rubber

Harvested latex serves as the primary raw material for producing natural rubber products such as gloves, balloons, and adhesives, valued for its elasticity and biodegradability. Reclaimed rubber, derived from recycled scrap tires and industrial waste, is extensively used in manufacturing automotive parts, footwear soles, and industrial mats, offering cost-effective durability and environmental benefits. The applications of reclaimed rubber complement harvested latex by promoting sustainable resource utilization in various rubber-based industries.

Challenges and Limitations in Both Methods

Latex harvesting faces challenges such as susceptibility to climatic variations, labor-intensive tapping processes, and the risk of tree damage affecting long-term yield. Rubber reclamation encounters limitations including contamination with impurities, high energy consumption during processing, and difficulty in restoring reclaimed rubber to original material properties. Both methods struggle with balancing cost-efficiency and sustainability while maintaining rubber quality for industrial applications.

Future Trends in Rubber Sourcing

Latex harvesting from rubber trees remains essential for producing natural rubber with superior elasticity and durability, while rubber reclamation from scrap tires addresses sustainability by recycling used materials into secondary products. Future trends in rubber sourcing emphasize integrating biotechnological advancements and automated tapping techniques to increase latex yield and quality, alongside expanding reclamation processes to meet eco-friendly standards and reduce environmental impact. Innovations in synthetic alternatives combined with circular economy practices will reshape global rubber supply chains, fostering a balance between natural resource conservation and market demand.

Latex Harvesting vs Rubber Reclamation Infographic

materialdif.com

materialdif.com