Compression molding involves placing pre-measured rubber material directly into an open mold cavity, where heat and pressure shape it into the final product, offering simplicity and cost-effectiveness for large, sturdy parts. Transfer molding uses a closed mold with a plunger that forces rubber into the mold cavity through channels, enabling more precise control and the ability to mold complex designs with inserts or delicate features. Both methods provide efficient rubber shaping options, but transfer molding excels in producing detailed components with tighter tolerances.

Table of Comparison

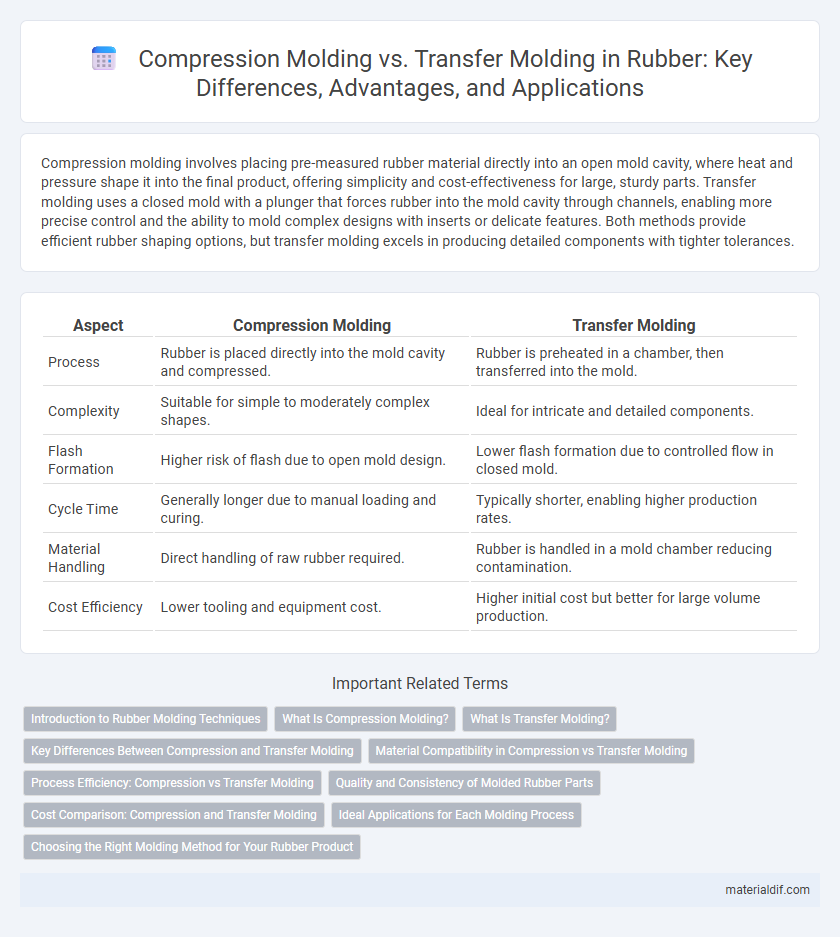

| Aspect | Compression Molding | Transfer Molding |

|---|---|---|

| Process | Rubber is placed directly into the mold cavity and compressed. | Rubber is preheated in a chamber, then transferred into the mold. |

| Complexity | Suitable for simple to moderately complex shapes. | Ideal for intricate and detailed components. |

| Flash Formation | Higher risk of flash due to open mold design. | Lower flash formation due to controlled flow in closed mold. |

| Cycle Time | Generally longer due to manual loading and curing. | Typically shorter, enabling higher production rates. |

| Material Handling | Direct handling of raw rubber required. | Rubber is handled in a mold chamber reducing contamination. |

| Cost Efficiency | Lower tooling and equipment cost. | Higher initial cost but better for large volume production. |

Introduction to Rubber Molding Techniques

Compression molding involves placing pre-measured rubber compounds into a heated mold cavity, where pressure and heat create a solid, shaped product with minimal waste and excellent mechanical properties. Transfer molding uses a ram to force rubber into a closed mold through a small channel, allowing for more complex shapes and better control of material flow, reducing defects such as voids or air pockets. Both techniques are crucial in rubber manufacturing, with compression molding favored for large, simple parts and transfer molding suited for intricate designs requiring tight tolerances.

What Is Compression Molding?

Compression molding is a manufacturing process where pre-measured rubber material is placed into a heated mold cavity, then subjected to pressure to form the desired shape. This method is ideal for producing large, simple parts with minimal material waste, often used in automotive and industrial applications. Compression molding provides excellent control over material flow and is cost-effective for high-volume production of durable rubber components.

What Is Transfer Molding?

Transfer molding is a rubber manufacturing process where pre-measured rubber compounds are placed into a heated chamber and then forced into a mold cavity under pressure. This method allows for precise control over material flow, making it ideal for complex shapes with intricate details. Compared to compression molding, transfer molding reduces flash and provides better dimensional accuracy, enhancing the quality of rubber parts.

Key Differences Between Compression and Transfer Molding

Compression molding involves placing uncured rubber directly into a heated mold cavity where pressure is applied to shape the part, while transfer molding forces pre-measured rubber through a channel into the mold under pressure. Transfer molding offers better control over material flow and is ideal for complex geometries and encapsulating inserts, whereas compression molding is simpler, cost-effective, and suitable for large, less intricate parts. The key differences lie in material handling, mold design complexity, and precision of the finished rubber components.

Material Compatibility in Compression vs Transfer Molding

Compression molding excels in processing heat-resistant and high-viscosity rubber materials like silicone and EPDM due to its direct application of heat and pressure. Transfer molding offers superior compatibility with complex rubber compounds containing fillers and additives, ensuring uniform material flow and reduced voids in intricate designs. Both methods support a range of elastomers, but transfer molding accommodates more intricate geometries and blends, optimizing material performance in precision rubber components.

Process Efficiency: Compression vs Transfer Molding

Compression molding offers higher process efficiency for large, simple rubber parts due to fewer steps and lower tooling costs, making it ideal for high-volume production. Transfer molding provides improved precision and better control over material flow, reducing defects in complex geometries but involves longer cycle times and higher tooling investments. Choosing between compression and transfer molding depends on balancing production speed, part complexity, and cost-effectiveness.

Quality and Consistency of Molded Rubber Parts

Compression molding delivers high-quality rubber parts with excellent consistency due to precise control over pressure and temperature during curing. Transfer molding enhances the flow of rubber into intricate molds, producing detailed components with superior dimensional accuracy and uniformity. Both methods optimize the physical properties of molded rubber, but transfer molding typically achieves better repeatability for complex geometries.

Cost Comparison: Compression and Transfer Molding

Compression molding offers lower tooling and production costs ideal for large, simple rubber parts due to its straightforward mold design and minimal material waste. Transfer molding incurs higher initial tooling expenses but enables precise, intricate component fabrication with better dimensional control, justifying the cost for complex parts and smaller production runs. Cost-effectiveness depends on part complexity, batch size, and material usage, with compression molding favored for bulk, less detailed items and transfer molding suited for detailed, lower-volume applications.

Ideal Applications for Each Molding Process

Compression molding is ideal for producing large, simple rubber parts with low to medium complexity, such as automotive seals and gaskets, due to its cost-effectiveness and ability to handle high-viscosity materials. Transfer molding excels in manufacturing intricate rubber components with complex geometries and insert molding applications, commonly used in electrical insulators and precision medical devices, thanks to its ability to fill detailed molds and minimize flash. Selecting the appropriate molding process depends on the part complexity, production volume, and required dimensional accuracy.

Choosing the Right Molding Method for Your Rubber Product

Compression molding offers cost-effective production for large, simple rubber parts with minimal waste, while transfer molding excels in creating intricate, high-precision components due to its controlled material flow. Selecting the appropriate molding method depends on factors such as part complexity, production volume, surface finish requirements, and tooling costs. Assessing these variables ensures optimal material performance, durability, and manufacturing efficiency tailored to specific rubber product applications.

Compression Molding vs Transfer Molding Infographic

materialdif.com

materialdif.com