Polyisoprene and polybutadiene are two primary types of synthetic rubber used in various applications. Polyisoprene closely mimics natural rubber, offering excellent elasticity, tensile strength, and resilience, making it ideal for products requiring high durability and flexibility. Polybutadiene provides superior wear resistance and low heat buildup, commonly used in tire manufacturing to enhance performance and longevity.

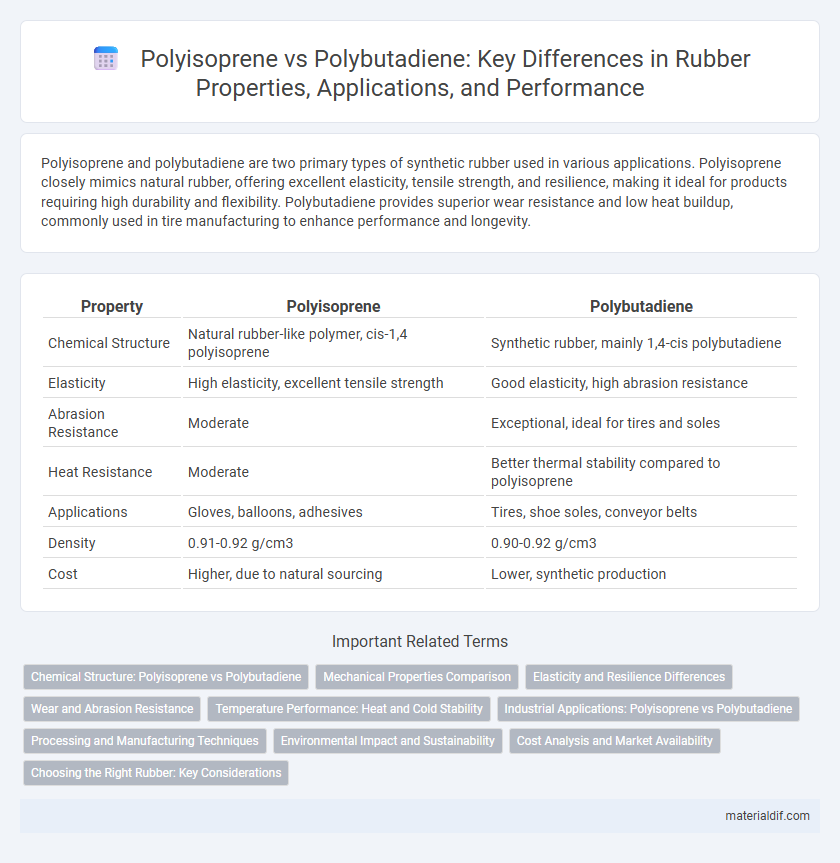

Table of Comparison

| Property | Polyisoprene | Polybutadiene |

|---|---|---|

| Chemical Structure | Natural rubber-like polymer, cis-1,4 polyisoprene | Synthetic rubber, mainly 1,4-cis polybutadiene |

| Elasticity | High elasticity, excellent tensile strength | Good elasticity, high abrasion resistance |

| Abrasion Resistance | Moderate | Exceptional, ideal for tires and soles |

| Heat Resistance | Moderate | Better thermal stability compared to polyisoprene |

| Applications | Gloves, balloons, adhesives | Tires, shoe soles, conveyor belts |

| Density | 0.91-0.92 g/cm3 | 0.90-0.92 g/cm3 |

| Cost | Higher, due to natural sourcing | Lower, synthetic production |

Chemical Structure: Polyisoprene vs Polybutadiene

Polyisoprene consists of repeating isoprene (C5H8) units with a structure featuring alternating double bonds in a cis-1,4 configuration, which provides elasticity and resilience similar to natural rubber. Polybutadiene is composed of butadiene (C4H6) monomers with variations in microstructure, including cis-1,4, trans-1,4, and 1,2-vinyl configurations, influencing toughness and wear resistance. The chemical structure differences between polyisoprene and polybutadiene directly impact their mechanical properties and typical applications in tires, seals, and elastomeric products.

Mechanical Properties Comparison

Polyisoprene exhibits high tensile strength and excellent elasticity, closely mimicking natural rubber's mechanical properties, making it ideal for applications requiring flexibility and durability. Polybutadiene offers superior abrasion resistance and impact toughness, with lower hysteresis loss, enhancing energy efficiency in tire manufacturing and industrial components. The distinct molecular structures influence their stress-strain behavior, where polyisoprene provides better resilience and polybutadiene excels in wear resistance and toughness.

Elasticity and Resilience Differences

Polyisoprene exhibits superior elasticity and resilience compared to polybutadiene, making it the preferred material for applications requiring high flexibility and energy return, such as car tires and medical gloves. Polybutadiene offers excellent abrasion resistance and low rolling resistance but has lower tensile strength and less elastic recovery than polyisoprene. The molecular structure of polyisoprene, closely mimicking natural rubber, contributes to its enhanced mechanical properties and durability under repeated stress.

Wear and Abrasion Resistance

Polyisoprene exhibits excellent wear resistance due to its natural rubber-like elasticity and high tensile strength, making it ideal for applications requiring durability under repetitive stress. Polybutadiene surpasses polyisoprene in abrasion resistance because of its low glass transition temperature and high resilience, which enable it to withstand harsh frictional forces in tires and industrial components. The choice between polyisoprene and polybutadiene hinges on balancing flexibility with abrasion performance to optimize rubber durability in specific use cases.

Temperature Performance: Heat and Cold Stability

Polyisoprene exhibits superior flexibility and resilience at low temperatures, maintaining elasticity down to around -50degC, making it ideal for cold weather applications. Polybutadiene offers excellent heat resistance with stable performance up to approximately 120degC, providing durability in elevated temperature environments. Both rubbers perform differently under thermal stress, where polyisoprene excels in cold stability and polybutadiene in heat endurance.

Industrial Applications: Polyisoprene vs Polybutadiene

Polyisoprene, a synthetic equivalent of natural rubber, is widely used in medical gloves, adhesives, and automotive tires due to its excellent elasticity and tensile strength. Polybutadiene stands out in industries requiring high wear resistance and low rolling resistance, such as tire treads, golf balls, and conveyor belts, because of its superior abrasion resistance and impact toughness. Industrial applications favor polyisoprene for flexibility and resilience, while polybutadiene is preferred for durability and performance under mechanical stress.

Processing and Manufacturing Techniques

Polyisoprene and polybutadiene differ significantly in their processing and manufacturing techniques due to their molecular structures and applications. Polyisoprene, closely resembling natural rubber, is typically processed via emulsion polymerization, enabling fine control over polymer chain length and microstructure, ideal for products requiring high elasticity and resilience such as tires and medical gloves. In contrast, polybutadiene is often synthesized through solution polymerization, facilitating production of rubbers with superior abrasion resistance and low-temperature flexibility, extensively used in tire treads and industrial rubber goods.

Environmental Impact and Sustainability

Polyisoprene, primarily sourced from natural rubber trees, offers a renewable resource with lower carbon emissions compared to synthetic alternatives like polybutadiene, which is derived from petroleum-based feedstocks. Polybutadiene production involves significant energy consumption and generates hazardous byproducts, raising environmental concerns around fossil fuel dependency and waste management. Choosing polyisoprene supports sustainability goals by promoting biodegradability and reducing ecological footprints associated with synthetic rubber manufacturing.

Cost Analysis and Market Availability

Polyisoprene, primarily sourced from natural rubber, typically incurs higher production costs due to complex extraction and refinement processes compared to synthetic Polybutadiene, which benefits from large-scale polymerization methods lowering its cost. Market availability favors Polybutadiene because its synthetic nature allows for consistent supply unaffected by agricultural variables impacting Polyisoprene harvests. Price fluctuations in Polyisoprene often correspond with natural rubber commodity trends, whereas Polybutadiene pricing remains more stable due to petrochemical feedstock control.

Choosing the Right Rubber: Key Considerations

Polyisoprene offers superior elasticity and tensile strength, making it ideal for applications requiring high resilience and flexibility, such as medical gloves and tires. Polybutadiene excels in abrasion resistance and low heat buildup, preferred for automotive tires and industrial belts where durability under stress is crucial. Selecting between polyisoprene and polybutadiene depends on specific performance requirements, including elasticity, wear resistance, and application environment.

Polyisoprene vs Polybutadiene Infographic

materialdif.com

materialdif.com