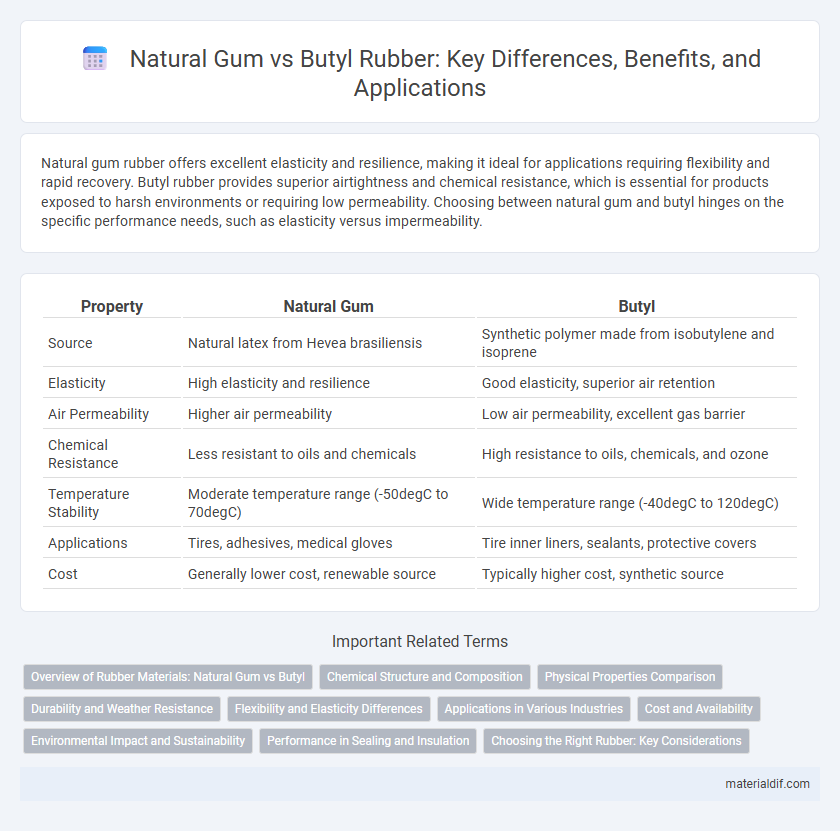

Natural gum rubber offers excellent elasticity and resilience, making it ideal for applications requiring flexibility and rapid recovery. Butyl rubber provides superior airtightness and chemical resistance, which is essential for products exposed to harsh environments or requiring low permeability. Choosing between natural gum and butyl hinges on the specific performance needs, such as elasticity versus impermeability.

Table of Comparison

| Property | Natural Gum | Butyl |

|---|---|---|

| Source | Natural latex from Hevea brasiliensis | Synthetic polymer made from isobutylene and isoprene |

| Elasticity | High elasticity and resilience | Good elasticity, superior air retention |

| Air Permeability | Higher air permeability | Low air permeability, excellent gas barrier |

| Chemical Resistance | Less resistant to oils and chemicals | High resistance to oils, chemicals, and ozone |

| Temperature Stability | Moderate temperature range (-50degC to 70degC) | Wide temperature range (-40degC to 120degC) |

| Applications | Tires, adhesives, medical gloves | Tire inner liners, sealants, protective covers |

| Cost | Generally lower cost, renewable source | Typically higher cost, synthetic source |

Overview of Rubber Materials: Natural Gum vs Butyl

Natural gum rubber is a renewable, biodegradable elastomer derived from the latex of Hevea brasiliensis trees, known for its excellent elasticity, tensile strength, and excellent resilience. Butyl rubber, a synthetic elastomer produced from isobutylene and a small amount of isoprene, offers superior impermeability to gases, chemical resistance, and aging stability, making it ideal for applications requiring airtight seals. The choice between natural gum and butyl rubber depends on factors such as environmental sustainability, durability, and specific performance requirements in industries like automotive, medical, and consumer goods.

Chemical Structure and Composition

Natural gum rubber is primarily composed of polyisoprene, a natural polymer with a cis-1,4 configuration, resulting in high elasticity and resilience due to its flexible carbon-carbon double bonds. Butyl rubber consists mainly of isobutylene with small amounts of isoprene, featuring saturated hydrocarbon chains that confer low permeability and excellent air retention but reduced elasticity compared to natural rubber. The distinct chemical structures influence their performance, with natural rubber providing superior tensile strength and butyl rubber offering enhanced impermeability and chemical resistance.

Physical Properties Comparison

Natural gum rubber exhibits high elasticity, excellent tensile strength, and superior resilience due to its cis-1,4-polyisoprene molecular structure, making it highly stretchable and tear-resistant. Butyl rubber, characterized by its isobutylene backbone with small isoprene content, demonstrates exceptional impermeability to gases, low air permeability, and superior resistance to ozone and weathering. While natural gum is prone to degradation under heat and oxygen, butyl rubber maintains stability in harsh environments, providing diverse applications based on differing physical property profiles.

Durability and Weather Resistance

Natural gum rubber exhibits excellent elasticity and resilience but tends to degrade faster under prolonged exposure to ozone, UV rays, and harsh weather conditions. Butyl rubber excels in durability and weather resistance due to its low permeability to air and gases, making it ideal for applications requiring airtight seals and resistance to environmental aging. The superior stability of butyl rubber extends the lifespan of products exposed to extreme weather compared to natural gum rubber.

Flexibility and Elasticity Differences

Natural gum rubber offers superior flexibility and elasticity due to its high molecular weight cis-1,4-polyisoprene structure, allowing it to stretch and recover efficiently under stress. Butyl rubber, composed of isobutylene with small amounts of isoprene, provides excellent air impermeability but exhibits lower elasticity and reduced flexibility compared to natural rubber. These differences make natural gum ideal for applications requiring high resilience and flexibility, while butyl is preferred for airtight seals and inner tubes needing durable, less elastic materials.

Applications in Various Industries

Natural gum rubber, derived from latex of rubber trees, excels in applications requiring high resilience, elasticity, and biodegradability, making it ideal for automotive tires, medical gloves, and adhesives. Butyl rubber, synthesized through copolymerization of isobutylene with isoprene, offers superior air impermeability and chemical resistance, widely used in inner tubes, sealants, and pharmaceutical stoppers. Each rubber type serves distinct industrial needs based on its unique properties, driving innovation in sectors like transportation, healthcare, and construction.

Cost and Availability

Natural gum rubber, derived from latex of rubber trees, generally has higher costs due to its complex harvesting process and seasonal availability, leading to supply fluctuations. Butyl rubber, a synthetic alternative produced through polymerization of isobutylene with small amounts of isoprene, offers more consistent availability and lower production costs driven by petrochemical feedstock stability. Manufacturers often choose butyl rubber for applications requiring cost efficiency and reliable supply, while natural gum rubber remains preferred for its superior elasticity and biodegradability despite higher price points.

Environmental Impact and Sustainability

Natural rubber, derived from the latex of Hevea brasiliensis trees, offers superior biodegradability and renewable sourcing, significantly reducing environmental pollution compared to synthetic butyl rubber, which is petroleum-based and non-biodegradable. The cultivation of natural rubber supports carbon sequestration and promotes biodiversity, while butyl rubber production involves higher energy consumption and contributes to fossil fuel depletion. Sustainability efforts emphasize expanding natural rubber plantations with responsible agroforestry practices to minimize deforestation and enhance ecosystem services.

Performance in Sealing and Insulation

Natural gum exhibits superior elasticity and flexibility, providing excellent sealing performance in dynamic applications by maintaining tight contact under varying pressures. Butyl rubber offers exceptional impermeability and resistance to gas diffusion, making it ideal for long-term insulation and airtight sealing in static environments. The choice between natural gum and butyl depends on the specific sealing or insulation requirements, balancing flexibility with durability and resistance to environmental factors.

Choosing the Right Rubber: Key Considerations

Natural gum rubber offers excellent elasticity, tensile strength, and biodegradability, making it ideal for environmentally conscious applications and products requiring high flexibility. Butyl rubber is favored for superior air impermeability, chemical resistance, and durability, particularly in automotive tires, sealing applications, and medical devices. Selecting the right rubber depends on factors like mechanical properties, environmental exposure, chemical resistance, and application-specific performance requirements.

Natural Gum vs Butyl Infographic

materialdif.com

materialdif.com