Thermoplastic Elastomers (TPE) offer the flexibility of being melted and reshaped multiple times, providing recyclability and ease of processing compared to traditional thermoset rubber, which cures into a permanent, cross-linked structure that cannot be remolded. TPEs combine the elastic properties of rubber with the processing advantages of plastics, making them ideal for applications requiring adaptability and cost-efficient manufacturing. Thermoset rubber, known for its superior thermal stability and chemical resistance, remains the material of choice for high-performance parts exposed to extreme conditions.

Table of Comparison

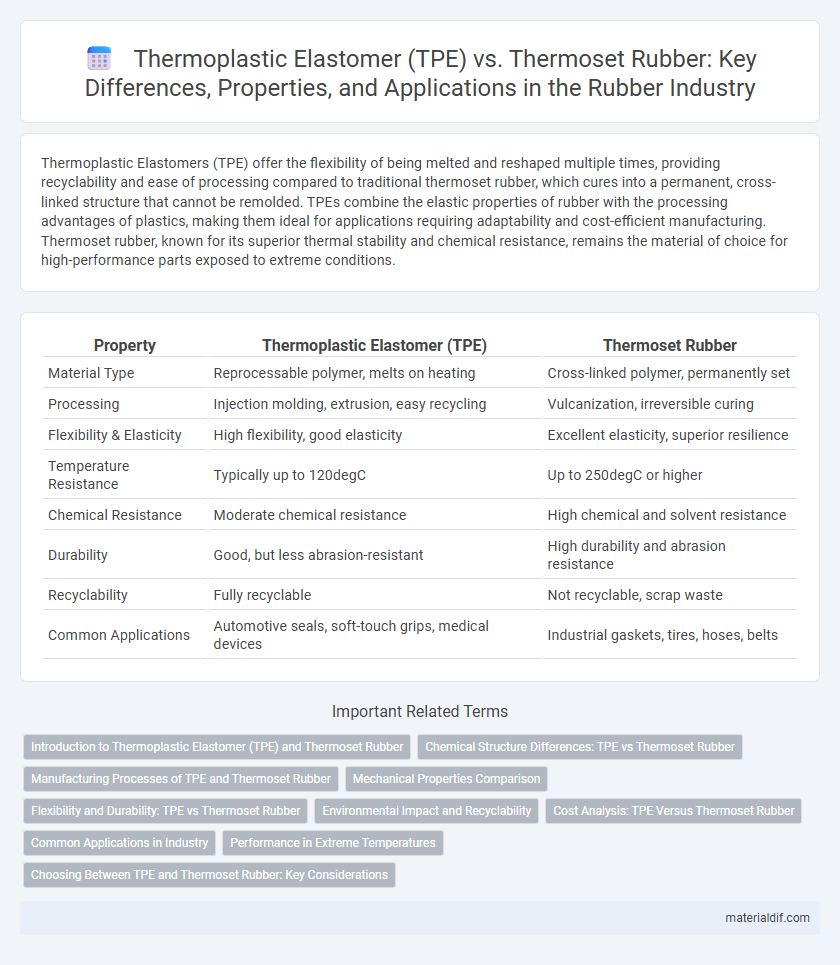

| Property | Thermoplastic Elastomer (TPE) | Thermoset Rubber |

|---|---|---|

| Material Type | Reprocessable polymer, melts on heating | Cross-linked polymer, permanently set |

| Processing | Injection molding, extrusion, easy recycling | Vulcanization, irreversible curing |

| Flexibility & Elasticity | High flexibility, good elasticity | Excellent elasticity, superior resilience |

| Temperature Resistance | Typically up to 120degC | Up to 250degC or higher |

| Chemical Resistance | Moderate chemical resistance | High chemical and solvent resistance |

| Durability | Good, but less abrasion-resistant | High durability and abrasion resistance |

| Recyclability | Fully recyclable | Not recyclable, scrap waste |

| Common Applications | Automotive seals, soft-touch grips, medical devices | Industrial gaskets, tires, hoses, belts |

Introduction to Thermoplastic Elastomer (TPE) and Thermoset Rubber

Thermoplastic Elastomers (TPE) combine the flexibility of rubber with the recyclability of plastics, offering easy processing through melting and reshaping without chemical change. Thermoset Rubber undergoes irreversible curing, forming strong cross-linked bonds that provide superior heat resistance and mechanical strength. TPE is favored in applications requiring repeated flexibility and recyclability, while thermoset rubber is preferred for durability in high-temperature environments.

Chemical Structure Differences: TPE vs Thermoset Rubber

Thermoplastic Elastomers (TPE) feature linear or branched polymer chains with physical cross-links, enabling them to soften upon heating and be reshaped, while thermoset rubber has a highly cross-linked, three-dimensional network formed through irreversible chemical vulcanization. These structural differences result in TPEs exhibiting elastic properties due to phase-separated block copolymers, whereas thermoset rubber's covalent cross-linking provides superior heat resistance and mechanical strength. The reversible nature of TPE's physical cross-links contrasts sharply with the permanent chemical bonds in thermoset rubber, influencing their recyclability and processing methods.

Manufacturing Processes of TPE and Thermoset Rubber

Thermoplastic Elastomer (TPE) manufacturing involves processes like injection molding and extrusion, allowing materials to be melted and reshaped repeatedly, enabling efficient recycling and rapid prototyping. Thermoset rubber production relies on vulcanization, a chemical cross-linking process performed under heat and pressure that irreversibly solidifies the material, resulting in superior thermal stability and mechanical strength. The contrasting manufacturing methods highlight TPE's flexibility and recyclability versus thermoset rubber's durability and heat resistance.

Mechanical Properties Comparison

Thermoplastic elastomers (TPE) provide superior flexibility and impact resistance compared to thermoset rubber, with elongation at break typically ranging from 300% to 700%, whereas thermoset rubber usually offers elongation between 200% and 500%. The tensile strength of TPE can reach up to 40 MPa, making it suitable for dynamic applications, while thermoset rubber often exceeds 50 MPa due to its cross-linked chemical structure that enhances durability and heat resistance. Despite these differences, TPE allows for easier recyclability and processing advantages, whereas thermoset rubber excels in high-temperature and chemically aggressive environments due to its irreversible curing.

Flexibility and Durability: TPE vs Thermoset Rubber

Thermoplastic elastomers (TPE) offer superior flexibility due to their ability to be repeatedly melted and reshaped, making them ideal for applications requiring dynamic movement and frequent deformation. Thermoset rubber, however, provides exceptional durability and resistance to heat, chemicals, and mechanical stress because its cross-linked polymer structure prevents remelting and enhances structural integrity. The choice between TPE and thermoset rubber depends on balancing the need for flexibility with long-term durability in specific industrial or consumer applications.

Environmental Impact and Recyclability

Thermoplastic elastomers (TPE) offer significant environmental advantages over thermoset rubber due to their ability to be remelted and reshaped, enabling efficient recycling and reducing landfill waste. Thermoset rubber, characterized by its permanent crosslinked structure, cannot be remolded after curing, leading to challenges in recycling and higher environmental disposal concerns. TPE's recyclability supports sustainable manufacturing practices and lowers carbon footprint compared to the energy-intensive production and disposal of thermoset rubber products.

Cost Analysis: TPE Versus Thermoset Rubber

Thermoplastic elastomers (TPE) generally offer lower production costs compared to thermoset rubber due to their ability to be melted and reprocessed, reducing material waste and enabling faster manufacturing cycles. Thermoset rubber requires longer curing times and specific mold setups, increasing labor and production expenses. Lifecycle cost analysis also favors TPE in applications requiring design flexibility and recyclability, despite thermoset rubber's superior heat and chemical resistance in high-performance environments.

Common Applications in Industry

Thermoplastic Elastomers (TPE) are widely used in automotive parts, consumer goods, and medical devices due to their recyclability, flexibility, and ease of processing. Thermoset rubber, with superior heat resistance and durability, is commonly applied in heavy-duty seals, gaskets, and industrial machinery components. Industries such as aerospace, electronics, and manufacturing rely on thermoset rubber for long-lasting performance under extreme conditions.

Performance in Extreme Temperatures

Thermoplastic Elastomers (TPE) maintain flexibility and elasticity in a temperature range of approximately -50degC to 150degC, making them suitable for moderate extreme conditions. Thermoset rubber, such as vulcanized rubber, outperforms TPE in extreme high temperatures above 200degC due to its crosslinked molecular structure, providing superior heat resistance and mechanical stability. The choice between TPE and thermoset rubber depends on the application's temperature demands, with thermoset rubber favored for sustained high-temperature exposure and TPE preferred for recyclability and moderate thermal resilience.

Choosing Between TPE and Thermoset Rubber: Key Considerations

Choosing between Thermoplastic Elastomer (TPE) and Thermoset Rubber depends on factors such as processing flexibility, mechanical properties, and end-use applications. TPE offers easy recyclability and excellent flexibility with fast processing cycles, making it ideal for applications requiring frequent molding changes and lightweight designs. Thermoset rubber provides superior heat resistance, chemical stability, and durability, making it suitable for high-performance seals, automotive parts, and industrial components needing long-term reliability.

Thermoplastic Elastomer (TPE) vs Thermoset Rubber Infographic

materialdif.com

materialdif.com