Butyl rubber offers excellent impermeability to gases and outstanding resistance to heat, aging, and chemicals, making it ideal for inner tubes and sealants. Chloroprene rubber (neoprene) provides superior oil, weather, and flame resistance with good mechanical properties, suitable for automotive hoses and gaskets. Choosing between butyl and chloroprene rubber depends on the specific application requirements such as chemical exposure, flexibility, and durability.

Table of Comparison

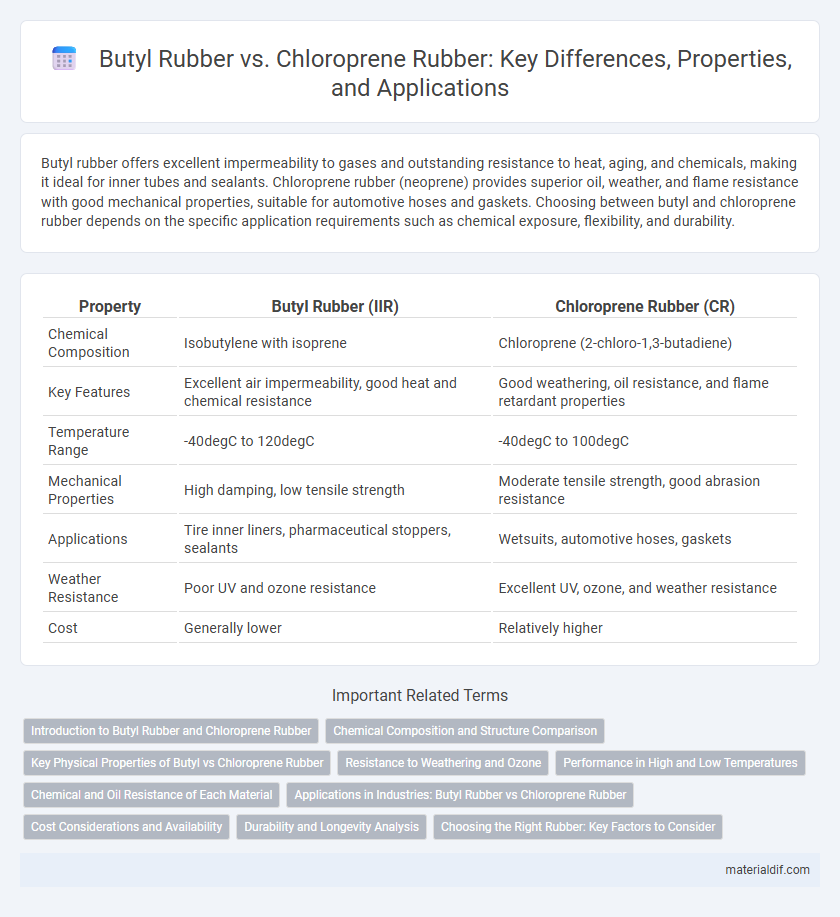

| Property | Butyl Rubber (IIR) | Chloroprene Rubber (CR) |

|---|---|---|

| Chemical Composition | Isobutylene with isoprene | Chloroprene (2-chloro-1,3-butadiene) |

| Key Features | Excellent air impermeability, good heat and chemical resistance | Good weathering, oil resistance, and flame retardant properties |

| Temperature Range | -40degC to 120degC | -40degC to 100degC |

| Mechanical Properties | High damping, low tensile strength | Moderate tensile strength, good abrasion resistance |

| Applications | Tire inner liners, pharmaceutical stoppers, sealants | Wetsuits, automotive hoses, gaskets |

| Weather Resistance | Poor UV and ozone resistance | Excellent UV, ozone, and weather resistance |

| Cost | Generally lower | Relatively higher |

Introduction to Butyl Rubber and Chloroprene Rubber

Butyl rubber, a synthetic elastomer primarily composed of isobutylene with a small amount of isoprene, offers excellent impermeability to gases and exceptional resistance to heat, ozone, and chemicals. Chloroprene rubber, also known as neoprene, is a synthetic rubber derived from the polymerization of chloroprene, featuring notable resistance to weathering, oils, and flame. Both elastomers serve critical roles in automotive, industrial, and consumer applications, with butyl rubber favored for inner tubes and seals, and chloroprene rubber commonly used in wetsuits, adhesives, and gaskets.

Chemical Composition and Structure Comparison

Butyl rubber is primarily composed of isobutylene with a small amount of isoprene, resulting in a saturated polymer chain that provides excellent impermeability and chemical resistance. Chloroprene rubber, also known as neoprene, consists of polychloroprene with chlorine atoms integrated into its polymer backbone, offering enhanced resistance to oils, chemicals, and weathering. The presence of chlorine in chloroprene rubber introduces polarity and cross-linking potential distinct from the hydrocarbon-based structure of butyl rubber, affecting their mechanical properties and applications.

Key Physical Properties of Butyl vs Chloroprene Rubber

Butyl rubber exhibits outstanding impermeability to gases and excellent resistance to heat, oxidation, and weathering, making it ideal for tire inner liners and pharmaceutical stoppers. Chloroprene rubber offers superior abrasion resistance, good chemical stability, and moderate resistance to oils and solvents, commonly used in automotive and industrial applications. Both rubbers differ significantly in tensile strength and elasticity, with butyl rubber providing better flexibility at low temperatures, while chloroprene rubber maintains higher mechanical strength under stress.

Resistance to Weathering and Ozone

Butyl rubber exhibits exceptional resistance to weathering and ozone due to its saturated polymer backbone, which prevents degradation from UV radiation and oxygen exposure. Chloroprene rubber offers moderate resistance but is more susceptible to cracking and deterioration under prolonged ozone and weather conditions. The superior stability of butyl rubber makes it ideal for applications requiring long-term exposure to harsh environmental elements.

Performance in High and Low Temperatures

Butyl rubber exhibits excellent performance in extreme low temperatures, maintaining flexibility and resilience down to -40degC, while chloroprene rubber performs better in moderate low temperatures but stiffens significantly below -20degC. In high-temperature applications, chloroprene rubber resists heat aging and oxidation up to 120degC, outperforming butyl rubber, which tends to degrade above 100degC. These temperature performance differences make butyl ideal for cold environments and chloroprene preferable in moderately hot conditions requiring weather and ozone resistance.

Chemical and Oil Resistance of Each Material

Butyl rubber exhibits superior chemical resistance with excellent stability against acids, alkalis, and polar solvents, making it ideal for applications exposed to harsh chemicals. Chloroprene rubber, or neoprene, offers moderate chemical resistance but excels in oil and fuel resistance due to its chlorine content, making it suitable for automotive and industrial use. Both materials provide durable sealing in challenging environments, but butyl rubber is preferable for chemical exposure, while chloroprene rubber is favored for oil resistance.

Applications in Industries: Butyl Rubber vs Chloroprene Rubber

Butyl rubber excels in applications requiring excellent impermeability to gases, making it ideal for tire inner linings, pharmaceutical stoppers, and protective gloves in the healthcare industry. Chloroprene rubber offers superior resistance to oil, chemicals, and weathering, leading to its widespread use in automotive parts, adhesives, and industrial coatings. Both rubbers serve distinct industrial roles based on their unique chemical properties, with butyl rubber preferred in sealing and insulation and chloroprene rubber favored in durability and chemical exposure contexts.

Cost Considerations and Availability

Butyl rubber typically carries a higher cost compared to chloroprene rubber due to its specialized production process and superior impermeability properties. Chloroprene rubber, also known as neoprene, is more widely available and generally more affordable, benefiting from broader industrial demand and established manufacturing infrastructure. Cost considerations and regional availability often make chloroprene rubber a preferred choice for applications with budget constraints, while butyl rubber is selected for situations requiring enhanced chemical resistance and air retention.

Durability and Longevity Analysis

Butyl rubber exhibits superior durability and longevity due to its excellent resistance to oxidation, weathering, and chemical exposure, making it ideal for applications requiring long-term airtight sealing. Chloroprene rubber offers good abrasion resistance and moderate aging properties but degrades faster under prolonged UV exposure and ozone, limiting its lifespan compared to butyl rubber. Performance tests reveal butyl rubber maintains mechanical integrity over extended periods, whereas chloroprene rubber may require more frequent replacement in harsh environments.

Choosing the Right Rubber: Key Factors to Consider

Choosing the right rubber depends on factors such as chemical resistance, temperature tolerance, and flexibility. Butyl rubber excels in impermeability and resistance to gas and chemicals, making it ideal for seals and inner tubes. Chloroprene rubber offers superior weather, ozone, and oil resistance, suitable for automotive and industrial applications exposed to harsh environments.

Butyl Rubber vs Chloroprene Rubber Infographic

materialdif.com

materialdif.com