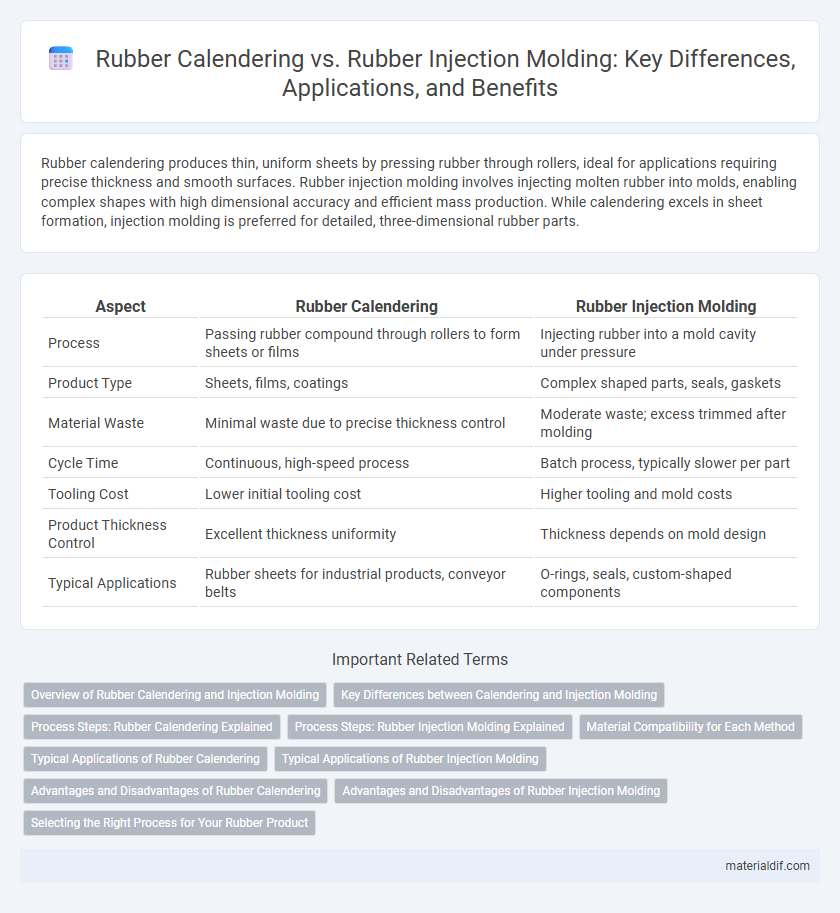

Rubber calendering produces thin, uniform sheets by pressing rubber through rollers, ideal for applications requiring precise thickness and smooth surfaces. Rubber injection molding involves injecting molten rubber into molds, enabling complex shapes with high dimensional accuracy and efficient mass production. While calendering excels in sheet formation, injection molding is preferred for detailed, three-dimensional rubber parts.

Table of Comparison

| Aspect | Rubber Calendering | Rubber Injection Molding |

|---|---|---|

| Process | Passing rubber compound through rollers to form sheets or films | Injecting rubber into a mold cavity under pressure |

| Product Type | Sheets, films, coatings | Complex shaped parts, seals, gaskets |

| Material Waste | Minimal waste due to precise thickness control | Moderate waste; excess trimmed after molding |

| Cycle Time | Continuous, high-speed process | Batch process, typically slower per part |

| Tooling Cost | Lower initial tooling cost | Higher tooling and mold costs |

| Product Thickness Control | Excellent thickness uniformity | Thickness depends on mold design |

| Typical Applications | Rubber sheets for industrial products, conveyor belts | O-rings, seals, custom-shaped components |

Overview of Rubber Calendering and Injection Molding

Rubber calendering involves passing rubber compounds through a series of rollers to create thin sheets or coatings with precise thickness and surface finish, commonly used for making sheets, belts, and coated fabrics. Rubber injection molding forces heated rubber into a mold cavity under high pressure, enabling the production of complex, detailed shapes with high dimensional accuracy and repeatability, ideal for automotive seals, gaskets, and small rubber components. Both processes are essential in the rubber manufacturing industry, offering distinct advantages depending on product design, volume, and application requirements.

Key Differences between Calendering and Injection Molding

Rubber calendering involves passing rubber compound through rollers to form thin sheets with consistent thickness, ideal for producing flat, uniform products like seals and gaskets. Rubber injection molding forces heated rubber into a mold cavity to create complex, three-dimensional components with precise shapes and detailed features. Calendering is best suited for continuous, large-scale sheet production, while injection molding excels in producing intricate parts with high replicability and minimal post-processing.

Process Steps: Rubber Calendering Explained

Rubber calendering involves passing rubber through a series of heated rollers to form continuous sheets or films with uniform thickness and surface finish, ideal for producing rubber sheets, coated fabrics, and conveyor belts. The process steps include mixing raw rubber with additives, feeding the compound between rollers, adjusting roller speed and pressure to achieve desired thickness, and then cooling and winding the rubber sheet. This method offers precise thickness control and high surface quality compared to rubber injection molding, which extrudes rubber into molds for complex shapes.

Process Steps: Rubber Injection Molding Explained

Rubber injection molding involves heating rubber compounds until pliable, then injecting them under high pressure into a mold cavity to form precise shapes. This process includes steps such as pre-heating the rubber, injecting it into the mold, curing the rubber within the mold, and finally demolding the finished part. Compared to rubber calendering, injection molding offers greater control over complex geometries and improved efficiency for high-volume production.

Material Compatibility for Each Method

Rubber calendering is highly compatible with thermoplastic elastomers and natural rubber, allowing precise control over sheet thickness suitable for producing gaskets, seals, and films. Rubber injection molding best suits synthetic rubbers such as silicone, neoprene, and nitrile, providing excellent dimensional accuracy and complex shapes for automotive and medical parts. Material selection depends on factors like thermal stability, viscosity, and curing behavior, where calendering favors polymers that can be rolled into sheets and injection molding requires materials with stable flow under heat and pressure.

Typical Applications of Rubber Calendering

Rubber calendering is primarily used to produce thin sheets, coatings, and layered composites for automotive hoses, conveyor belts, and tire treads, where uniform thickness and smooth surfaces are critical. It excels in applications requiring large, continuous rubber sheets for protective linings, sealants, and industrial gloves, offering precise control over thickness and texture. This process is ideal for manufacturing flexible, durable parts with consistent material properties over extensive surface areas.

Typical Applications of Rubber Injection Molding

Rubber injection molding is commonly used for producing complex, high-precision components such as seals, gaskets, and valves in automotive, aerospace, and medical industries. This method excels in manufacturing small to medium-sized parts with intricate designs and tight tolerances, providing high efficiency and reduced material waste. Typical applications include rubber boots, O-rings, diaphragms, and vibration dampers, where consistent quality and durability are critical.

Advantages and Disadvantages of Rubber Calendering

Rubber calendering offers precise control over thickness and surface finish, making it ideal for producing uniform sheets and coatings with excellent dimensional accuracy. However, it is limited by lower production speeds and less complex shape capabilities compared to rubber injection molding, which excels in forming intricate parts. The process is cost-effective for large, flat products but struggles with material waste and setup flexibility, unlike injection molding's efficient use of material and versatility.

Advantages and Disadvantages of Rubber Injection Molding

Rubber injection molding offers high precision and repeatability, making it ideal for producing complex and high-volume rubber parts with consistent quality. It features shorter cycle times compared to calendering, reducing labor costs and minimizing material waste, though it requires expensive molds and machinery, leading to higher initial investment. However, the process limitations include potential difficulties in molding large or thick parts and sensitivity to rubber compounds' flow properties, which can impact final product performance.

Selecting the Right Process for Your Rubber Product

Rubber calendering involves passing rubber compound through rollers to create thin, uniform sheets ideal for applications requiring consistent thickness and surface finish, such as conveyor belts and rubber flooring. Rubber injection molding heats and injects rubber into molds, allowing for complex, precise shapes perfect for high-volume production of seals, gaskets, and automotive parts. Selecting the right process depends on product design complexity, production volume, and desired material properties, with calendering suited for flat, sheet-based products and injection molding preferred for detailed, three-dimensional components.

Rubber Calendering vs Rubber Injection Molding Infographic

materialdif.com

materialdif.com