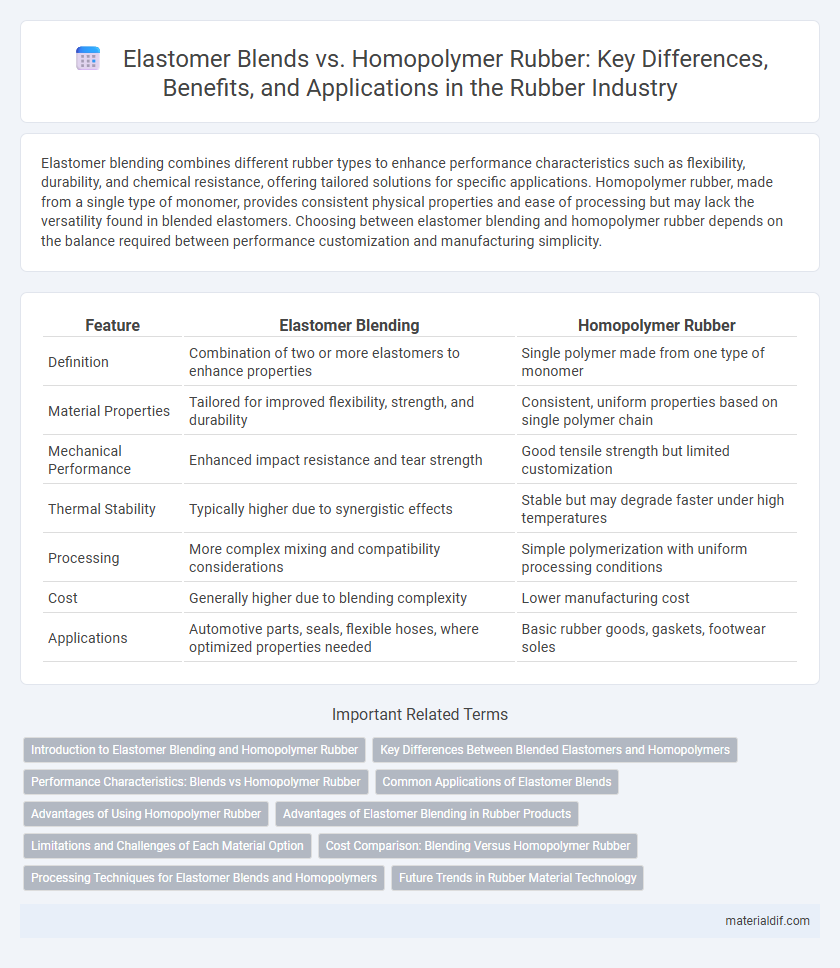

Elastomer blending combines different rubber types to enhance performance characteristics such as flexibility, durability, and chemical resistance, offering tailored solutions for specific applications. Homopolymer rubber, made from a single type of monomer, provides consistent physical properties and ease of processing but may lack the versatility found in blended elastomers. Choosing between elastomer blending and homopolymer rubber depends on the balance required between performance customization and manufacturing simplicity.

Table of Comparison

| Feature | Elastomer Blending | Homopolymer Rubber |

|---|---|---|

| Definition | Combination of two or more elastomers to enhance properties | Single polymer made from one type of monomer |

| Material Properties | Tailored for improved flexibility, strength, and durability | Consistent, uniform properties based on single polymer chain |

| Mechanical Performance | Enhanced impact resistance and tear strength | Good tensile strength but limited customization |

| Thermal Stability | Typically higher due to synergistic effects | Stable but may degrade faster under high temperatures |

| Processing | More complex mixing and compatibility considerations | Simple polymerization with uniform processing conditions |

| Cost | Generally higher due to blending complexity | Lower manufacturing cost |

| Applications | Automotive parts, seals, flexible hoses, where optimized properties needed | Basic rubber goods, gaskets, footwear soles |

Introduction to Elastomer Blending and Homopolymer Rubber

Elastomer blending combines different polymer types to tailor properties such as elasticity, tensile strength, and chemical resistance, enhancing performance for specific applications. Homopolymer rubber consists of a single monomer, resulting in uniform molecular structure and consistent physical characteristics ideal for predictable usage. Understanding the differences in molecular composition and performance between elastomer blends and homopolymer rubbers is crucial for optimizing material selection in manufacturing and product design.

Key Differences Between Blended Elastomers and Homopolymers

Blended elastomers combine two or more polymers to enhance mechanical strength, flexibility, and chemical resistance, whereas homopolymer rubber consists of a single polymer, offering uniform consistency and predictable properties. Elastomer blends provide tailored performance for specific applications, optimizing factors like abrasion resistance and elasticity compared to the more limited property set of homopolymers. The key differences lie in their composition, versatility in application, and the ability of blends to achieve superior performance characteristics through synergistic effects.

Performance Characteristics: Blends vs Homopolymer Rubber

Elastomer blending improves performance characteristics by combining the strengths of different polymers, resulting in enhanced flexibility, abrasion resistance, and tensile strength compared to homopolymer rubber. Homopolymer rubber offers uniform properties, but lacks the tailored balance of durability and elasticity found in blends. Blended elastomers optimize mechanical properties and chemical resistance, making them preferable for specialized applications in automotive and industrial sectors.

Common Applications of Elastomer Blends

Elastomer blends offer enhanced performance by combining the unique properties of different rubber types, making them ideal for automotive seals, footwear, and industrial gaskets. These blends provide improved flexibility, abrasion resistance, and chemical stability compared to homopolymer rubber, which is often limited to single-function uses like standard tires or simple hoses. Industries leverage elastomer blending to achieve custom material characteristics required in demanding environments such as oil drilling, conveyor belts, and vibration damping components.

Advantages of Using Homopolymer Rubber

Homopolymer rubber offers superior uniformity in molecular structure, resulting in consistent mechanical properties and improved processability compared to elastomer blends. Its high purity ensures enhanced elastic recovery, abrasion resistance, and chemical stability, making it ideal for precision applications. Manufacturers benefit from reduced material variability, leading to predictable performance and simplified quality control.

Advantages of Elastomer Blending in Rubber Products

Elastomer blending offers enhanced mechanical properties and improved flexibility compared to homopolymer rubber, enabling superior performance in diverse applications such as automotive tires and industrial seals. The compatibility of different elastomers allows for tailored chemical resistance, temperature stability, and abrasion resistance, resulting in more durable and versatile rubber products. This customization capability reduces material costs and extends product lifespan, providing economic benefits alongside improved functionality.

Limitations and Challenges of Each Material Option

Elastomer blending faces challenges such as phase separation and compatibility issues that can compromise mechanical properties and increase processing complexity. Homopolymer rubber exhibits limitations in tailoring specific performance attributes due to its uniform molecular structure, often resulting in reduced flexibility and resilience under diverse conditions. Both materials require careful formulation and processing optimization to balance cost, performance, and durability in specialized applications.

Cost Comparison: Blending Versus Homopolymer Rubber

Elastomer blending typically reduces overall material costs by combining different polymers to optimize performance at a lower price point than homopolymer rubber. Homopolymer rubber often demands higher expenses due to its purity and consistent properties but may offer superior long-term durability. Cost efficiency in elastomer blending arises from tailored formulations that balance price and performance, making it a preferred choice in budget-sensitive applications.

Processing Techniques for Elastomer Blends and Homopolymers

Elastomer blending involves mixing different rubber types, often using twin-screw extruders for enhanced compatibility and tailored properties, while homopolymer rubber processing relies heavily on single-screw extruders for uniform molecular structure maintenance. Techniques like internal mixing and solution blending optimize elastomer blends by improving dispersion and cross-linking efficiency, contrasting with homopolymers' simpler mixing and vulcanization processes. Processing parameters such as temperature, shear rate, and mixing time are critical in both, but elastomer blends require more precise control to achieve the desired mechanical and chemical performance.

Future Trends in Rubber Material Technology

Elastomer blending offers enhanced material properties by combining the strength, flexibility, and chemical resistance of different rubbers, outperforming traditional homopolymer rubber in durability and performance. Future trends in rubber material technology emphasize the development of sustainable elastomer blends incorporating bio-based polymers and advanced fillers to improve recyclability and reduce environmental impact. Innovations in nanocomposite additives and processing techniques further enable tailored property profiles, meeting the growing demands for high-performance applications in automotive, aerospace, and consumer products.

Elastomer Blending vs Homopolymer Rubber Infographic

materialdif.com

materialdif.com