Rubber compounding involves mixing raw rubber with various chemical additives like fillers, antioxidants, and curing agents to enhance performance characteristics such as durability, elasticity, and resistance to heat or chemicals. Rubber blending, on the other hand, refers to the physical mixing of different types of rubber polymers to combine their inherent properties and achieve a balanced material profile. Understanding the distinctions between compounding and blending is crucial for optimizing the manufacturing process and ensuring the final rubber product meets specific application requirements.

Table of Comparison

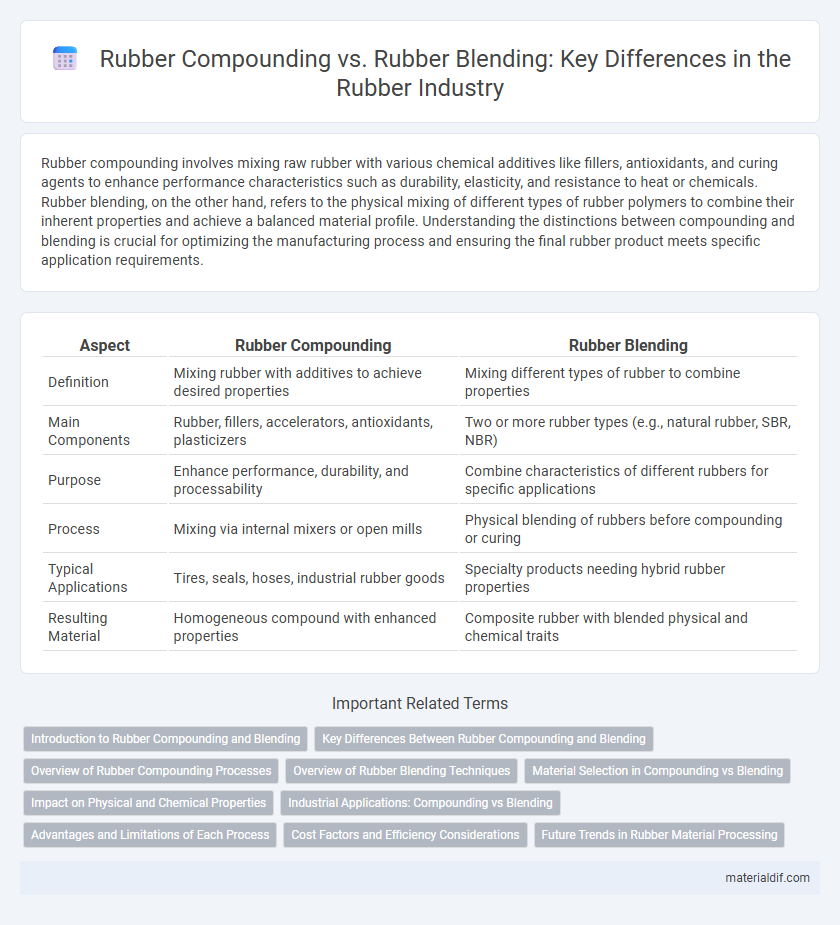

| Aspect | Rubber Compounding | Rubber Blending |

|---|---|---|

| Definition | Mixing rubber with additives to achieve desired properties | Mixing different types of rubber to combine properties |

| Main Components | Rubber, fillers, accelerators, antioxidants, plasticizers | Two or more rubber types (e.g., natural rubber, SBR, NBR) |

| Purpose | Enhance performance, durability, and processability | Combine characteristics of different rubbers for specific applications |

| Process | Mixing via internal mixers or open mills | Physical blending of rubbers before compounding or curing |

| Typical Applications | Tires, seals, hoses, industrial rubber goods | Specialty products needing hybrid rubber properties |

| Resulting Material | Homogeneous compound with enhanced properties | Composite rubber with blended physical and chemical traits |

Introduction to Rubber Compounding and Blending

Rubber compounding involves the precise mixing of base polymers with fillers, curing agents, and additives to enhance physical properties and performance for specific applications. Rubber blending refers to the physical combination of different types of rubbers to achieve desired characteristics by leveraging the properties of each polymer. Both processes are critical in tailoring rubber materials for industries such as automotive, aerospace, and consumer goods.

Key Differences Between Rubber Compounding and Blending

Rubber compounding involves the precise mixing of raw rubber with additives such as fillers, accelerators, and antioxidants to enhance specific mechanical and chemical properties, whereas rubber blending primarily focuses on physically combining different types of rubber polymers to achieve desired performance characteristics. Compounding requires a detailed formulation targeting attributes like elasticity, durability, and resistance to heat or chemicals, while blending aims to improve processability and cost-effectiveness by balancing the properties of varied rubber types. Key differences lie in the purpose, complexity, and the type of materials combined, with compounding being a more chemically-driven process and blending relying on physical mixing.

Overview of Rubber Compounding Processes

Rubber compounding involves the precise mixing of raw rubber with additives such as fillers, plasticizers, antioxidants, and curing agents to enhance physical properties and performance characteristics. This process requires controlled dispersion and homogenization to achieve desired viscosity, elasticity, and durability for specific applications. In contrast, rubber blending typically refers to mixing different types of rubber to combine their inherent properties without extensive additive integration.

Overview of Rubber Blending Techniques

Rubber blending involves the precise mixing of different types of natural and synthetic rubbers to enhance properties like elasticity, durability, and resistance to heat or chemicals. Techniques such as mechanical mixing using internal mixers, two-roll mills, and ultrasonic blending enable uniform dispersion of polymers and additives, ensuring consistent performance in the final product. Advanced blending methods like dynamic vulcanization and solution blending optimize compatibility and improve the physical characteristics of rubber compounds for diverse industrial applications.

Material Selection in Compounding vs Blending

Rubber compounding involves the precise selection and formulation of base polymers, fillers, plasticizers, curing agents, and accelerators to achieve specific mechanical and chemical properties tailored for performance requirements. In contrast, rubber blending primarily focuses on mixing different types of rubber polymers to combine their inherent characteristics, often without extensive additive customization. Material selection in compounding emphasizes chemical compatibility and functional additives to optimize vulcanization and durability, whereas blending prioritizes polymer compatibility and balance of physical properties.

Impact on Physical and Chemical Properties

Rubber compounding involves combining raw rubber with additives like fillers, curing agents, and plasticizers to enhance mechanical strength, elasticity, and resistance to heat and chemicals. Rubber blending primarily mixes different types of rubber polymers to achieve a balance of properties such as flexibility, tensile strength, and abrasion resistance. The choice between compounding and blending significantly impacts the final product's durability, chemical stability, and performance under stress.

Industrial Applications: Compounding vs Blending

Rubber compounding involves mixing raw rubber with additives like fillers, curing agents, and processing oils to tailor mechanical properties for specific industrial applications such as automotive tires, seals, and hoses. Rubber blending, on the other hand, combines two or more types of raw or partially processed rubbers to achieve a balanced performance profile, suited for applications requiring enhanced flexibility or chemical resistance. Industrial applications benefit from compounding's precise control over vulcanization and performance characteristics, while blending is primarily used to optimize cost-efficiency and material compatibility.

Advantages and Limitations of Each Process

Rubber compounding enhances material properties by precisely mixing raw rubber with additives such as fillers, plasticizers, and curing agents, resulting in improved durability, elasticity, and resistance to abrasion and chemicals; however, it requires careful formulation and control to avoid defects like phase separation or uneven dispersion. Rubber blending involves physically combining different types of rubbers to achieve a balanced set of mechanical and chemical characteristics, offering flexibility in tailoring properties but often facing challenges in achieving homogeneous mixtures and consistent performance. Each process plays a critical role in optimizing rubber performance for applications ranging from automotive tires to industrial seals, with compounding excelling in property customization and blending enabling versatile material combinations.

Cost Factors and Efficiency Considerations

Rubber compounding involves mixing raw rubber with various additives to achieve specific properties, often resulting in higher costs due to specialized chemicals and precise formulation control. Rubber blending typically refers to combining different types of rubber to balance performance and reduce expenses, offering increased efficiency in large-scale production. Cost factors favor blending when raw materials are compatible, while compounding provides superior customization despite higher processing complexity and time.

Future Trends in Rubber Material Processing

Future trends in rubber material processing emphasize advanced rubber compounding techniques utilizing nanomaterials and bio-based additives to enhance mechanical properties and environmental sustainability. Rubber blending increasingly integrates smart polymers and recycled rubber to achieve superior durability and cost-effectiveness in automotive and industrial applications. Emerging technologies like AI-driven formulation and precise mixing equipment optimize compound consistency, driving innovation in rubber product performance.

Rubber Compounding vs Rubber Blending Infographic

materialdif.com

materialdif.com