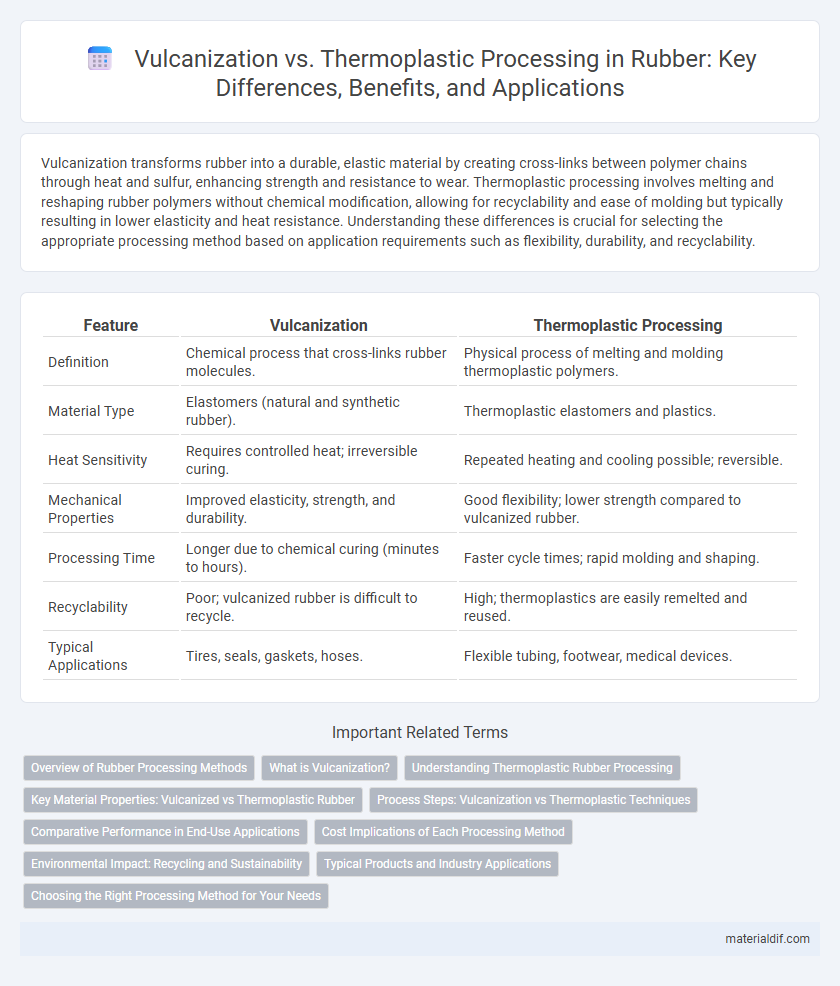

Vulcanization transforms rubber into a durable, elastic material by creating cross-links between polymer chains through heat and sulfur, enhancing strength and resistance to wear. Thermoplastic processing involves melting and reshaping rubber polymers without chemical modification, allowing for recyclability and ease of molding but typically resulting in lower elasticity and heat resistance. Understanding these differences is crucial for selecting the appropriate processing method based on application requirements such as flexibility, durability, and recyclability.

Table of Comparison

| Feature | Vulcanization | Thermoplastic Processing |

|---|---|---|

| Definition | Chemical process that cross-links rubber molecules. | Physical process of melting and molding thermoplastic polymers. |

| Material Type | Elastomers (natural and synthetic rubber). | Thermoplastic elastomers and plastics. |

| Heat Sensitivity | Requires controlled heat; irreversible curing. | Repeated heating and cooling possible; reversible. |

| Mechanical Properties | Improved elasticity, strength, and durability. | Good flexibility; lower strength compared to vulcanized rubber. |

| Processing Time | Longer due to chemical curing (minutes to hours). | Faster cycle times; rapid molding and shaping. |

| Recyclability | Poor; vulcanized rubber is difficult to recycle. | High; thermoplastics are easily remelted and reused. |

| Typical Applications | Tires, seals, gaskets, hoses. | Flexible tubing, footwear, medical devices. |

Overview of Rubber Processing Methods

Vulcanization transforms natural or synthetic rubber through heat and sulfur, enhancing elasticity, strength, and durability by creating cross-linked molecular structures. Thermoplastic processing involves heating rubber-like polymers to a pliable state, allowing reshaping without altering chemical properties, suitable for repeated molding and recycling. Rubber processing methods vary in application, with vulcanization preferred for durable tires and seals, while thermoplastic processing supports flexible, recyclable products like elastomeric components.

What is Vulcanization?

Vulcanization is a chemical process that enhances rubber's elasticity, strength, and durability by forming cross-links between polymer chains using sulfur or other curatives. This transformation turns raw, sticky rubber into a more stable and heat-resistant material, essential for tires, seals, and industrial products. Unlike thermoplastic processing, vulcanization creates a permanent, three-dimensional network that cannot be remelted or reshaped.

Understanding Thermoplastic Rubber Processing

Thermoplastic rubber processing involves heating the material to a temperature where it becomes soft and moldable without undergoing permanent chemical changes, allowing it to be reshaped multiple times. Unlike vulcanization, which crosslinks rubber molecules through a sulfur-curing process to enhance durability and elasticity, thermoplastic rubbers combine the elastic properties of rubber with the processing advantages of plastics. This results in materials that are easier to recycle and process using conventional thermoplastic techniques such as injection molding and extrusion.

Key Material Properties: Vulcanized vs Thermoplastic Rubber

Vulcanized rubber exhibits enhanced elasticity, resilience, and thermal stability due to its cross-linked polymer chains, making it ideal for applications requiring durability and resistance to deformation. Thermoplastic rubber offers superior processability and recyclability, characterized by its reversible melting behavior and lower tensile strength compared to vulcanized counterparts. The choice between vulcanized and thermoplastic rubber depends on performance requirements such as mechanical strength, heat resistance, and reusability in manufacturing processes.

Process Steps: Vulcanization vs Thermoplastic Techniques

Vulcanization involves heating raw rubber with sulfur to create cross-links between polymer chains, enhancing elasticity and strength through a chemical curing process typically conducted at 140-160degC for 20-30 minutes. Thermoplastic processing melts rubber compounds at elevated temperatures, usually above 200degC, allowing them to be reshaped and cooled without chemical alteration, involving steps like extrusion, injection molding, or compression molding. Unlike vulcanization's irreversible chemical transformation, thermoplastic techniques enable repeated melting and solidification, offering distinct advantages in manufacturing efficiency and recyclability.

Comparative Performance in End-Use Applications

Vulcanized rubber exhibits superior mechanical strength, elasticity, and heat resistance compared to thermoplastic elastomers, making it ideal for demanding applications like tires, industrial belts, and seals. Thermoplastic processing offers recyclability and ease of fabrication with reversible softening, but vulcanized rubber's cross-linked network provides enhanced durability and chemical resistance for long-term performance. End-use applications requiring high fatigue resistance and dimensional stability favor vulcanized rubber, while thermoplastics are preferred in lighter-duty or flexible designs.

Cost Implications of Each Processing Method

Vulcanization, a chemical process forming cross-linked rubber molecules, typically incurs higher initial costs due to extended curing times and specialized equipment but yields durable, heat-resistant products with longer lifespans. Thermoplastic processing involves melting and reshaping rubber compounds, offering lower production costs and faster cycle times, which benefit high-volume manufacturing despite producing materials with reduced elasticity and heat resistance. Cost implications must balance upfront investment against product performance requirements and production scale.

Environmental Impact: Recycling and Sustainability

Vulcanized rubber, due to its cross-linked polymer structure, is challenging to recycle and often ends up in landfills, contributing to environmental pollution. Thermoplastic processing allows repeated melting and reshaping, significantly enhancing recyclability and reducing waste. Sustainable rubber manufacturing increasingly favors thermoplastic elastomers to minimize ecological footprints and support circular economies.

Typical Products and Industry Applications

Vulcanization produces durable, elastic rubber materials commonly used in automotive tires, seals, and industrial hoses due to enhanced heat and wear resistance. Thermoplastic processing creates recyclable, flexible products such as flexible tubing, footwear soles, and automotive interior components, benefiting industries emphasizing rapid prototyping and lightweight design. Both methods serve distinct market demands, with vulcanized rubber dominating heavy-duty applications and thermoplastics preferred in consumer goods and electronics.

Choosing the Right Processing Method for Your Needs

Vulcanization enhances rubber's durability and elasticity by creating cross-linked polymer chains, making it ideal for applications requiring heat resistance and mechanical strength. Thermoplastic processing offers easier recyclability and rapid molding without chemical transformation, suited for flexible, recyclable products. Selecting the right method depends on balancing performance needs, production efficiency, and environmental considerations specific to your project.

Vulcanization vs Thermoplastic Processing Infographic

materialdif.com

materialdif.com