Vulcanization is a chemical process that enhances rubber's elasticity and strength by forming cross-links between polymer chains using sulfur or other curatives. Curing refers broadly to the hardening or setting of rubber, which may involve vulcanization or other methods like peroxide curing, to improve material properties and durability. Understanding the difference between vulcanization and curing is crucial for selecting appropriate processing techniques in rubber manufacturing.

Table of Comparison

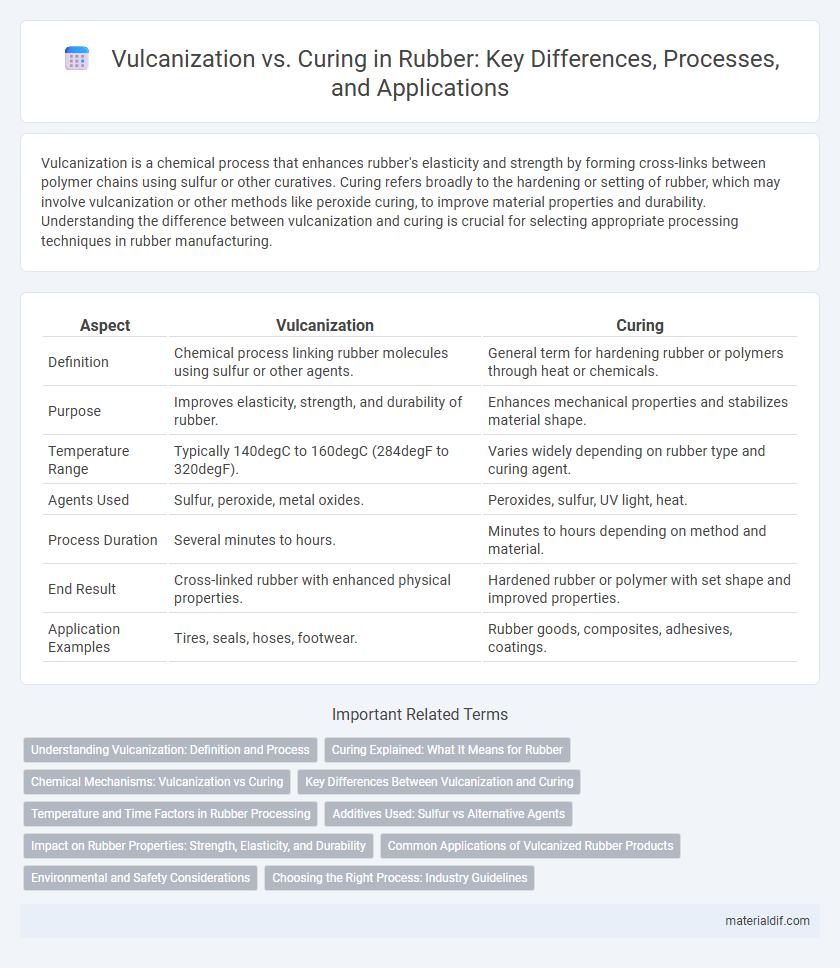

| Aspect | Vulcanization | Curing |

|---|---|---|

| Definition | Chemical process linking rubber molecules using sulfur or other agents. | General term for hardening rubber or polymers through heat or chemicals. |

| Purpose | Improves elasticity, strength, and durability of rubber. | Enhances mechanical properties and stabilizes material shape. |

| Temperature Range | Typically 140degC to 160degC (284degF to 320degF). | Varies widely depending on rubber type and curing agent. |

| Agents Used | Sulfur, peroxide, metal oxides. | Peroxides, sulfur, UV light, heat. |

| Process Duration | Several minutes to hours. | Minutes to hours depending on method and material. |

| End Result | Cross-linked rubber with enhanced physical properties. | Hardened rubber or polymer with set shape and improved properties. |

| Application Examples | Tires, seals, hoses, footwear. | Rubber goods, composites, adhesives, coatings. |

Understanding Vulcanization: Definition and Process

Vulcanization is a chemical process that enhances rubber's properties by forming cross-links between polymer chains using sulfur or other curatives, significantly improving elasticity, strength, and durability. This transformation occurs through heating rubber with sulfur, which creates a three-dimensional network that stabilizes the material, making it more resistant to deformation and environmental factors. Understanding vulcanization is essential for producing high-performance rubber products used in tires, industrial goods, and consumer items.

Curing Explained: What It Means for Rubber

Curing refers to the chemical process that transforms raw rubber into a durable material by cross-linking polymer chains, enhancing its elasticity, strength, and heat resistance. This process typically involves heat and curing agents like sulfur or peroxides, which create sulfur bridges between polymer molecules, stabilizing the rubber structure. Proper curing ensures improved mechanical properties and longevity, making it essential for applications in tires, seals, and various rubber products.

Chemical Mechanisms: Vulcanization vs Curing

Vulcanization involves the formation of cross-links between polymer chains in rubber through sulfur bridges, enhancing elasticity and mechanical strength by creating a three-dimensional network. Curing, a broader term, refers to the chemical process that hardens rubber or other polymers via various agents such as peroxides, which generate carbon-carbon cross-links, improving heat resistance and durability. The key difference lies in the type of cross-linking chemistry: vulcanization specifically uses sulfur-based cross-linking, while curing can employ multiple mechanisms depending on the rubber formulation and desired properties.

Key Differences Between Vulcanization and Curing

Vulcanization involves chemically cross-linking rubber molecules with sulfur or other agents to enhance elasticity, strength, and durability, while curing generally refers to the broader process of hardening or setting rubber through heat or chemical reactions. Vulcanization specifically targets the formation of sulfur cross-links that improve mechanical properties, whereas curing may include various methods like peroxide curing or radiation curing, not limited to sulfur. The key difference lies in vulcanization's sulfur cross-linking mechanism that transforms raw rubber into a resilient, elastic material, unlike curing, which encompasses diverse hardening techniques for different rubber types.

Temperature and Time Factors in Rubber Processing

Vulcanization of rubber typically occurs at higher temperatures, usually between 140degC and 180degC, and requires precise timing to achieve optimal cross-linking for enhanced durability and elasticity. Curing processes can vary widely, with temperatures ranging from 120degC to 160degC depending on the rubber compound and desired properties, where longer curing times improve mechanical strength but may lead to over-curing if not carefully controlled. Balancing temperature and time in both vulcanization and curing is critical to ensure consistent rubber performance, preventing under- or over-processing that compromises material integrity.

Additives Used: Sulfur vs Alternative Agents

Vulcanization primarily uses sulfur as the key additive to create cross-links between rubber polymer chains, enhancing elasticity and durability. Alternative curing agents such as peroxides, metal oxides, and resin systems are employed in curing processes to achieve specific material properties like heat resistance or improved aging characteristics. Selecting sulfur or alternative additives depends on the desired mechanical performance, processing conditions, and end-use applications of the rubber product.

Impact on Rubber Properties: Strength, Elasticity, and Durability

Vulcanization significantly enhances rubber's strength, elasticity, and durability by forming cross-links between polymer chains, resulting in improved resistance to deformation and wear. Curing, which includes vulcanization and other processes, ensures the rubber attains desired physical properties by controlling temperature, pressure, and time, but the degree of cross-linking during vulcanization primarily dictates the mechanical performance. Optimizing vulcanization conditions is critical for achieving maximum tensile strength, superior elasticity, and extended lifespan in rubber products.

Common Applications of Vulcanized Rubber Products

Vulcanized rubber products are widely used in automotive tires, conveyor belts, and industrial hoses due to their enhanced strength, elasticity, and resistance to wear and temperature. These applications benefit from the cross-linked molecular structure created during vulcanization, which improves durability and performance under mechanical stress. Common industries utilizing vulcanized rubber include automotive manufacturing, heavy machinery, and consumer goods.

Environmental and Safety Considerations

Vulcanization and curing processes significantly impact environmental and safety aspects in rubber manufacturing. Vulcanization typically involves sulfur and accelerators that can release harmful emissions, requiring stringent air quality controls and protective equipment to safeguard workers. Curing alternatives using peroxide systems reduce toxic byproducts and lower volatile organic compound (VOC) emissions, enhancing workplace safety and minimizing environmental pollution.

Choosing the Right Process: Industry Guidelines

Vulcanization and curing are critical processes in rubber manufacturing, with vulcanization involving the formation of cross-links using sulfur or other curatives to enhance elasticity and durability, while curing broadly refers to the chemical reactions that solidify rubber compounds. Industry guidelines recommend selecting vulcanization for applications demanding high tensile strength and abrasion resistance, such as tire production and heavy-duty rubber goods. Curing is preferred for less mechanically intensive products like seals and gaskets, where flexibility and moderate durability are sufficient.

Vulcanization vs Curing Infographic

materialdif.com

materialdif.com