Filled rubber contains additives such as carbon black or silica that enhance mechanical strength, abrasion resistance, and durability compared to unfilled rubber, which lacks these reinforcing agents. Unfilled rubber typically offers greater elasticity and better electrical insulation but has lower tensile strength and reduced wear resistance. Choosing between filled and unfilled rubber depends on specific application requirements, balancing performance characteristics like flexibility, toughness, and resistance to environmental factors.

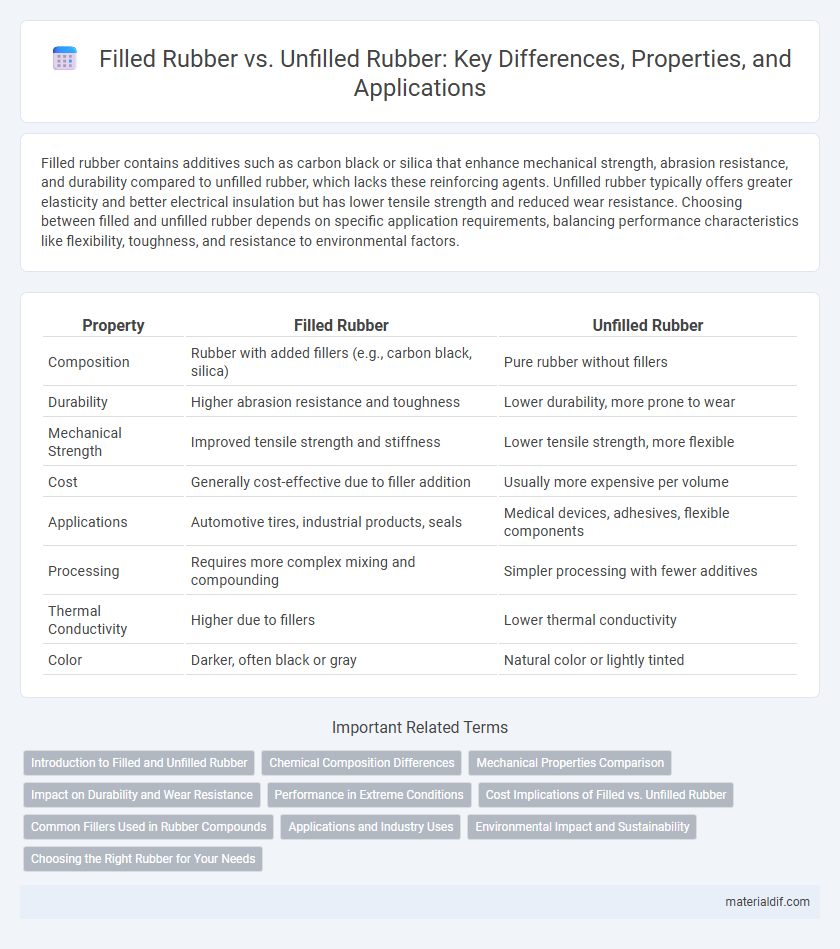

Table of Comparison

| Property | Filled Rubber | Unfilled Rubber |

|---|---|---|

| Composition | Rubber with added fillers (e.g., carbon black, silica) | Pure rubber without fillers |

| Durability | Higher abrasion resistance and toughness | Lower durability, more prone to wear |

| Mechanical Strength | Improved tensile strength and stiffness | Lower tensile strength, more flexible |

| Cost | Generally cost-effective due to filler addition | Usually more expensive per volume |

| Applications | Automotive tires, industrial products, seals | Medical devices, adhesives, flexible components |

| Processing | Requires more complex mixing and compounding | Simpler processing with fewer additives |

| Thermal Conductivity | Higher due to fillers | Lower thermal conductivity |

| Color | Darker, often black or gray | Natural color or lightly tinted |

Introduction to Filled and Unfilled Rubber

Filled rubber contains additives such as carbon black or silica that enhance mechanical properties, improve durability, and increase resistance to wear and tear. Unfilled rubber, also known as pure rubber, lacks these reinforcing agents, resulting in greater elasticity but lower strength and abrasion resistance. The selection between filled and unfilled rubber depends on application-specific requirements such as flexibility, resilience, and hardness.

Chemical Composition Differences

Filled rubber incorporates additives such as carbon black, silica, or clay, enhancing properties like tensile strength, abrasion resistance, and thermal stability by altering the polymer matrix with reinforcing fillers. Unfilled rubber consists primarily of natural or synthetic polymers without these reinforcing agents, resulting in more elastic but less durable material due to the absence of filler-induced chemical cross-linking. The chemical composition of filled rubber includes polymer chains embedded with filler particles, which interact chemically and physically to improve mechanical performance compared to the simpler hydrocarbon structure of unfilled rubber.

Mechanical Properties Comparison

Filled rubber, reinforced with additives like carbon black or silica, exhibits significantly enhanced tensile strength, abrasion resistance, and durability compared to unfilled rubber. The mechanical properties of filled rubber, such as higher modulus and improved tear resistance, make it ideal for applications requiring robust performance under stress. Unfilled rubber, while more flexible and softer, lacks the reinforcement that improves wear resistance and mechanical stability found in filled rubber compounds.

Impact on Durability and Wear Resistance

Filled rubber contains additives such as carbon black or silica that enhance its durability and wear resistance by improving tensile strength and abrasion resistance. Unfilled rubber, lacking these reinforcing fillers, typically exhibits lower mechanical strength and faster degradation under stress and friction. The presence of fillers significantly increases the lifespan and performance of rubber products in demanding applications.

Performance in Extreme Conditions

Filled rubber compounds exhibit enhanced durability and resistance in extreme conditions due to the addition of reinforcing fillers like carbon black or silica, which improve tensile strength, abrasion resistance, and thermal stability. Unfilled rubber, while more flexible and softer, generally shows lower performance under high stress, elevated temperatures, and harsh chemical environments, making it less suitable for demanding industrial or automotive applications. The optimal choice depends on the specific requirements of temperature tolerance, mechanical stress, and environmental exposure.

Cost Implications of Filled vs. Unfilled Rubber

Filled rubber contains additives such as carbon black or silica, which enhance mechanical properties but increase material and processing costs compared to unfilled rubber. Unfilled rubber offers lower initial costs due to the absence of fillers but may result in reduced durability and higher long-term maintenance expenses. The choice between filled and unfilled rubber depends on balancing upfront investment against performance requirements and lifecycle cost efficiency.

Common Fillers Used in Rubber Compounds

Common fillers used in rubber compounds include carbon black, silica, clay, calcium carbonate, and talc, each enhancing different properties like tensile strength, abrasion resistance, and cost efficiency. Filled rubber typically exhibits improved mechanical properties, durability, and chemical resistance compared to unfilled rubber, which lacks these additives. The choice and concentration of fillers significantly influence the performance characteristics and application suitability of the rubber product.

Applications and Industry Uses

Filled rubber, reinforced with additives like carbon black or silica, offers enhanced durability and abrasion resistance, making it ideal for automotive tires, industrial belts, and heavy-duty hoses. Unfilled rubber, lacking these fillers, provides superior elasticity and flexibility, commonly used in medical devices, seals, and flexible tubing. Various industries select filled or unfilled rubber based on specific mechanical properties required for performance and longevity in their applications.

Environmental Impact and Sustainability

Filled rubber incorporates additives like carbon black or silica to enhance durability and performance but often results in more complex recycling challenges due to the presence of non-rubber fillers. Unfilled rubber, composed mainly of natural or synthetic polymers without fillers, offers easier biodegradability and simpler recycling processes, reducing environmental impact. Choosing unfilled rubber supports sustainability goals by minimizing waste and promoting circular economy practices in rubber production.

Choosing the Right Rubber for Your Needs

Filled rubber contains additives like carbon black or silica, enhancing strength, durability, and abrasion resistance, making it ideal for industrial applications requiring high performance. Unfilled rubber offers greater elasticity, flexibility, and softness, suitable for products needing cushioning or flexibility such as seals, gaskets, or vibration dampening. Selecting the right rubber depends on balancing factors like mechanical strength, wear resistance, and flexibility based on the specific application's demands.

Filled Rubber vs Unfilled Rubber Infographic

materialdif.com

materialdif.com