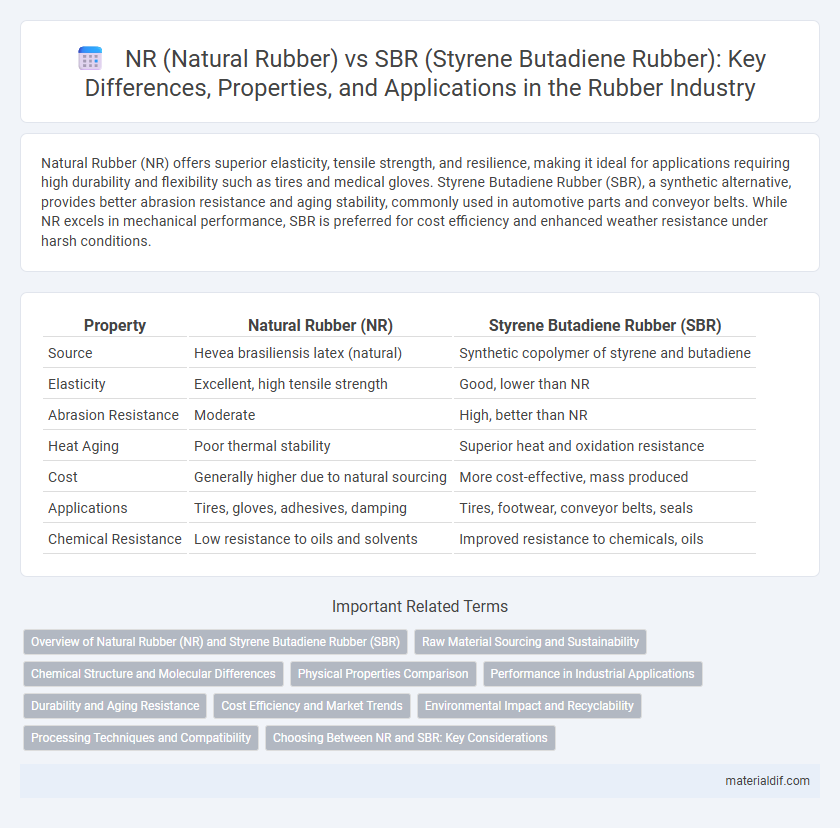

Natural Rubber (NR) offers superior elasticity, tensile strength, and resilience, making it ideal for applications requiring high durability and flexibility such as tires and medical gloves. Styrene Butadiene Rubber (SBR), a synthetic alternative, provides better abrasion resistance and aging stability, commonly used in automotive parts and conveyor belts. While NR excels in mechanical performance, SBR is preferred for cost efficiency and enhanced weather resistance under harsh conditions.

Table of Comparison

| Property | Natural Rubber (NR) | Styrene Butadiene Rubber (SBR) |

|---|---|---|

| Source | Hevea brasiliensis latex (natural) | Synthetic copolymer of styrene and butadiene |

| Elasticity | Excellent, high tensile strength | Good, lower than NR |

| Abrasion Resistance | Moderate | High, better than NR |

| Heat Aging | Poor thermal stability | Superior heat and oxidation resistance |

| Cost | Generally higher due to natural sourcing | More cost-effective, mass produced |

| Applications | Tires, gloves, adhesives, damping | Tires, footwear, conveyor belts, seals |

| Chemical Resistance | Low resistance to oils and solvents | Improved resistance to chemicals, oils |

Overview of Natural Rubber (NR) and Styrene Butadiene Rubber (SBR)

Natural Rubber (NR) is a polymer derived from the latex of Hevea brasiliensis trees, renowned for its high tensile strength, elasticity, and excellent abrasion resistance. Styrene Butadiene Rubber (SBR) is a synthetic copolymer made from styrene and butadiene, offering superior aging resistance and cost-effectiveness compared to NR. NR is preferred for applications requiring exceptional mechanical properties, while SBR is widely used in tires and industrial products due to its versatility and improved weather resistance.

Raw Material Sourcing and Sustainability

Natural Rubber (NR) is sourced from Hevea brasiliensis trees, offering a renewable and biodegradable material, whereas Styrene Butadiene Rubber (SBR) is a synthetic polymer derived from petrochemical sources, contributing to fossil fuel depletion. NR harvesting involves tapping latex from rubber trees, supporting sustainable forestry practices when managed properly, while SBR production relies on non-renewable crude oil refining processes with higher carbon emissions. The environmental footprint of NR is generally lower due to its biodegradability and potential for carbon sequestration in rubber plantations, making it a more sustainable option compared to petroleum-based SBR.

Chemical Structure and Molecular Differences

Natural Rubber (NR) consists primarily of polyisoprene with a cis-1,4 configuration, giving it high elasticity and tensile strength due to its regular molecular structure. Styrene Butadiene Rubber (SBR) is a synthetic copolymer of styrene and butadiene, exhibiting a more random chain structure, which results in lower elasticity but improved abrasion resistance and aging stability compared to NR. The chemical difference lies in NR's natural polymerization of isoprene monomers versus SBR's controlled copolymerization, affecting their molecular weight distribution and physical properties.

Physical Properties Comparison

Natural Rubber (NR) exhibits superior tensile strength, elasticity, and resilience compared to Styrene Butadiene Rubber (SBR), making it ideal for applications requiring high durability and flexibility. SBR, however, offers better abrasion resistance and aging stability, especially under heat and ozone exposure, which enhances its performance in automotive and industrial uses. The differences in molecular structure influence NR's superior tear resistance and SBR's improved resistance to chemicals and weathering.

Performance in Industrial Applications

Natural Rubber (NR) offers superior tensile strength, elasticity, and abrasion resistance, making it ideal for high-performance industrial products such as conveyor belts, tires, and vibration dampers. Styrene Butadiene Rubber (SBR) excels in heat resistance, aging stability, and cost-effectiveness, commonly used in automotive tires, footwear, and gaskets where durability under harsh conditions is essential. Industrial applications requiring flexibility and resilience favor NR, while those demanding enhanced weather resistance and lower price points prioritize SBR.

Durability and Aging Resistance

Natural Rubber (NR) offers excellent elasticity and tensile strength but has limited durability and poor aging resistance when exposed to ozone, UV light, and heat. Styrene Butadiene Rubber (SBR) demonstrates superior aging resistance with enhanced durability, maintaining performance under harsh environmental conditions and prolonged use. The choice between NR and SBR depends on the specific application requirements for longevity and resistance to environmental degradation.

Cost Efficiency and Market Trends

Natural Rubber (NR) often outperforms Styrene Butadiene Rubber (SBR) in cost efficiency due to lower raw material expenses and higher elasticity, which reduces overall production costs in automotive and industrial applications. Market trends indicate a rising demand for NR in sectors prioritizing sustainability and performance, while SBR remains popular for its consistent quality and cost-effectiveness in high-volume, synthetic rubber products. Fluctuations in crude oil prices heavily influence SBR costs, whereas NR prices are more affected by agricultural factors, shaping procurement strategies in the rubber industry.

Environmental Impact and Recyclability

Natural Rubber (NR) is biodegradable and derived from renewable resources, leading to lower environmental impact compared to Styrene Butadiene Rubber (SBR), which is synthetic and petroleum-based, contributing to higher carbon emissions and pollution. NR supports sustainable forestry practices, whereas SBR production relies on fossil fuels and generates non-biodegradable waste. Recycling processes for NR are limited but more environmentally friendly, while SBR recycling poses challenges due to its chemical composition and often involves energy-intensive methods.

Processing Techniques and Compatibility

Natural Rubber (NR) offers superior elasticity and resilience, benefiting from vulcanization with sulfur for enhanced mechanical properties, whereas Styrene Butadiene Rubber (SBR) undergoes emulsion polymerization yielding improved abrasion resistance and aging stability. Processing techniques for NR typically involve mastication to reduce molecular weight before compounding, while SBR requires thorough mixing with additives to optimize polymer dispersion and compatibility with fillers. NR's polar structure limits compatibility with non-polar fillers, whereas SBR exhibits better blend compatibility with various synthetic rubbers and reinforcing agents due to its copolymeric nature.

Choosing Between NR and SBR: Key Considerations

Natural Rubber (NR) offers superior tensile strength, elasticity, and resilience, making it ideal for products requiring high durability and flexibility, such as tires and industrial hoses. Styrene Butadiene Rubber (SBR) provides better abrasion resistance and aging stability, excelling in applications exposed to heat, oils, and weathering, like automotive parts and conveyor belts. Choosing between NR and SBR depends on specific performance criteria including mechanical properties, environmental resistance, and cost-effectiveness tailored to the intended use.

NR (Natural Rubber) vs SBR (Styrene Butadiene Rubber) Infographic

materialdif.com

materialdif.com