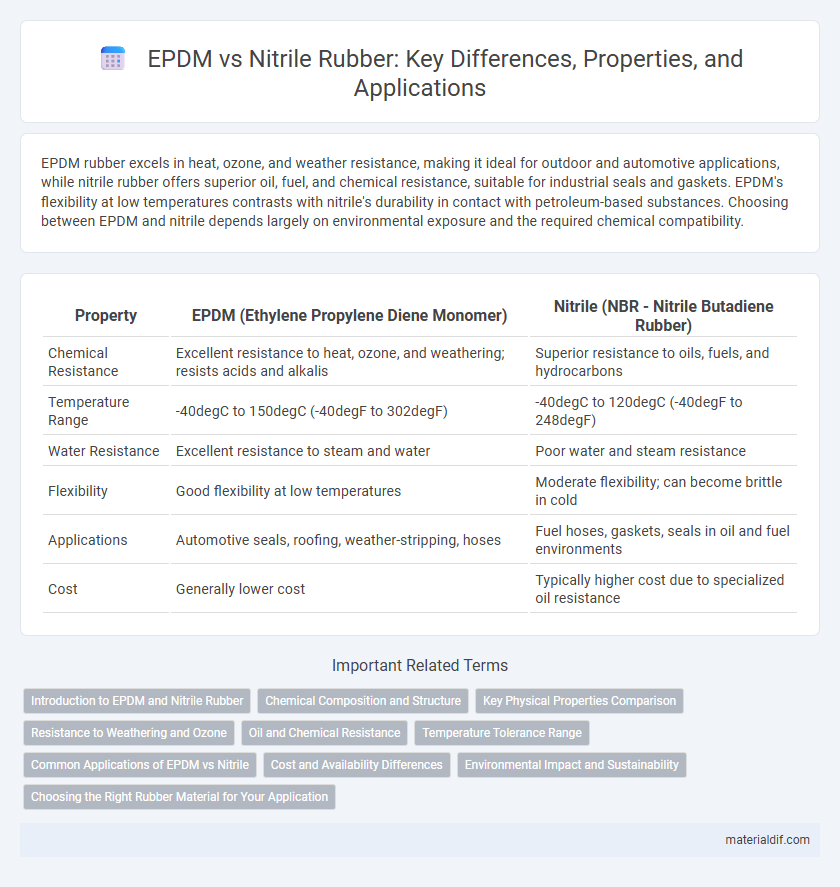

EPDM rubber excels in heat, ozone, and weather resistance, making it ideal for outdoor and automotive applications, while nitrile rubber offers superior oil, fuel, and chemical resistance, suitable for industrial seals and gaskets. EPDM's flexibility at low temperatures contrasts with nitrile's durability in contact with petroleum-based substances. Choosing between EPDM and nitrile depends largely on environmental exposure and the required chemical compatibility.

Table of Comparison

| Property | EPDM (Ethylene Propylene Diene Monomer) | Nitrile (NBR - Nitrile Butadiene Rubber) |

|---|---|---|

| Chemical Resistance | Excellent resistance to heat, ozone, and weathering; resists acids and alkalis | Superior resistance to oils, fuels, and hydrocarbons |

| Temperature Range | -40degC to 150degC (-40degF to 302degF) | -40degC to 120degC (-40degF to 248degF) |

| Water Resistance | Excellent resistance to steam and water | Poor water and steam resistance |

| Flexibility | Good flexibility at low temperatures | Moderate flexibility; can become brittle in cold |

| Applications | Automotive seals, roofing, weather-stripping, hoses | Fuel hoses, gaskets, seals in oil and fuel environments |

| Cost | Generally lower cost | Typically higher cost due to specialized oil resistance |

Introduction to EPDM and Nitrile Rubber

EPDM (Ethylene Propylene Diene Monomer) and Nitrile rubber are synthetic elastomers widely used in sealing and automotive applications due to their distinct chemical resistance properties. EPDM offers superior resistance to weathering, ozone, and aging, making it ideal for outdoor and high-temperature environments, while Nitrile rubber excels in oil, fuel, and hydrocarbon resistance, suitable for industrial and mechanical components. Both materials provide excellent abrasion resistance and elasticity, with EPDM commonly found in roofing membranes and weather seals, and Nitrile favored for fuel hoses, gaskets, and gloves.

Chemical Composition and Structure

EPDM rubber is a terpolymer composed of ethylene, propylene, and a diene monomer, featuring a saturated carbon backbone that provides superior resistance to ozone, heat, and weathering. Nitrile rubber (NBR) consists of copolymers of acrylonitrile and butadiene, with polar nitrile groups that enhance oil and fuel resistance but reduce flexibility at low temperatures. The key structural difference lies in EPDM's saturated backbone and non-polar nature versus NBR's unsaturated backbone with polar nitrile groups, influencing their chemical resistance profiles and mechanical properties.

Key Physical Properties Comparison

EPDM rubber offers superior resistance to heat, ozone, and weathering, with a temperature range of -40degC to 150degC, making it ideal for outdoor applications. Nitrile rubber exhibits excellent oil, fuel, and chemical resistance, functioning effectively between -30degC and 120degC. Tensile strength for EPDM typically ranges from 7 to 20 MPa, while nitrile shows a slightly higher range from 10 to 25 MPa, highlighting its robustness in mechanical applications.

Resistance to Weathering and Ozone

EPDM rubber exhibits exceptional resistance to weathering and ozone, making it ideal for outdoor applications exposed to harsh environmental conditions. Nitrile rubber, while excellent for oil and fuel resistance, degrades more rapidly when subjected to prolonged ozone and UV exposure. The superior ozone and weathering durability of EPDM ensures longer service life in automotive seals, roofing membranes, and electrical insulation.

Oil and Chemical Resistance

EPDM rubber offers excellent resistance to heat, ozone, and weathering but has poor resistance to oils and petroleum-based chemicals, making it unsuitable for applications involving prolonged exposure to hydrocarbons. Nitrile rubber (NBR) excels in oil and chemical resistance, particularly against petroleum, mineral oils, and fuels, providing durability in automotive and industrial sealing applications. For environments with aggressive oil or chemical exposure, nitrile rubber is the preferred choice due to its superior impermeability and resistance to degradation.

Temperature Tolerance Range

EPDM rubber offers superior temperature tolerance, functioning effectively between -50degC and 150degC, making it ideal for outdoor and high-heat applications. Nitrile rubber typically operates within a narrower range of -30degC to 100degC, excelling in resistance to oils and fuels but with less heat endurance. Selecting EPDM or Nitrile depends on the specific temperature demands of the environment and chemical exposure requirements.

Common Applications of EPDM vs Nitrile

EPDM rubber excels in applications requiring excellent weather, ozone, and heat resistance, commonly used in automotive weatherstripping, roofing membranes, and electrical insulation. Nitrile rubber is preferred for applications demanding superior oil, fuel, and chemical resistance, making it ideal for fuel hoses, gaskets, seals, and disposable gloves. Both elastomers serve critical roles in industrial and automotive sectors, with EPDM dominating outdoor and high-temperature environments, while nitrile leads in oil-exposed and mechanical sealing applications.

Cost and Availability Differences

EPDM rubber generally offers lower costs and broader availability compared to nitrile rubber, making it a preferred choice for budget-sensitive applications requiring weather and ozone resistance. Nitrile rubber, while typically higher in price, provides superior oil and fuel resistance, which justifies its cost in industrial and automotive sectors. Market supply trends indicate that EPDM is more widely produced and stocked, ensuring easier procurement and faster delivery than nitrile.

Environmental Impact and Sustainability

EPDM rubber offers superior environmental benefits due to its excellent resistance to UV radiation, ozone, and weathering, resulting in longer product lifespan and reduced waste. Nitrile rubber, derived from petrochemicals, has higher environmental concerns related to fossil fuel extraction and lower biodegradability compared to EPDM. Choosing EPDM supports sustainability initiatives by minimizing ecological footprint through enhanced durability and potential for recycling.

Choosing the Right Rubber Material for Your Application

EPDM rubber offers excellent resistance to weather, ozone, and heat, making it ideal for outdoor applications and exposure to harsh environmental conditions. Nitrile rubber provides superior oil, fuel, and chemical resistance, which is essential for automotive, industrial, and fuel system components. Selecting the right material depends on the specific requirements of your application, including exposure to chemicals, temperature ranges, and environmental factors.

EPDM vs Nitrile Infographic

materialdif.com

materialdif.com