Conductive rubber contains carbon or metal fillers that enable it to transmit electricity, making it ideal for applications requiring electrical conductivity and static discharge protection. In contrast, insulative rubber is composed of materials like silicone or neoprene that prevent electrical currents, providing excellent electrical insulation and protection against shocks. Choosing between conductive and insulative rubber depends on whether conductivity or insulation is critical for the intended use in electronic or industrial applications.

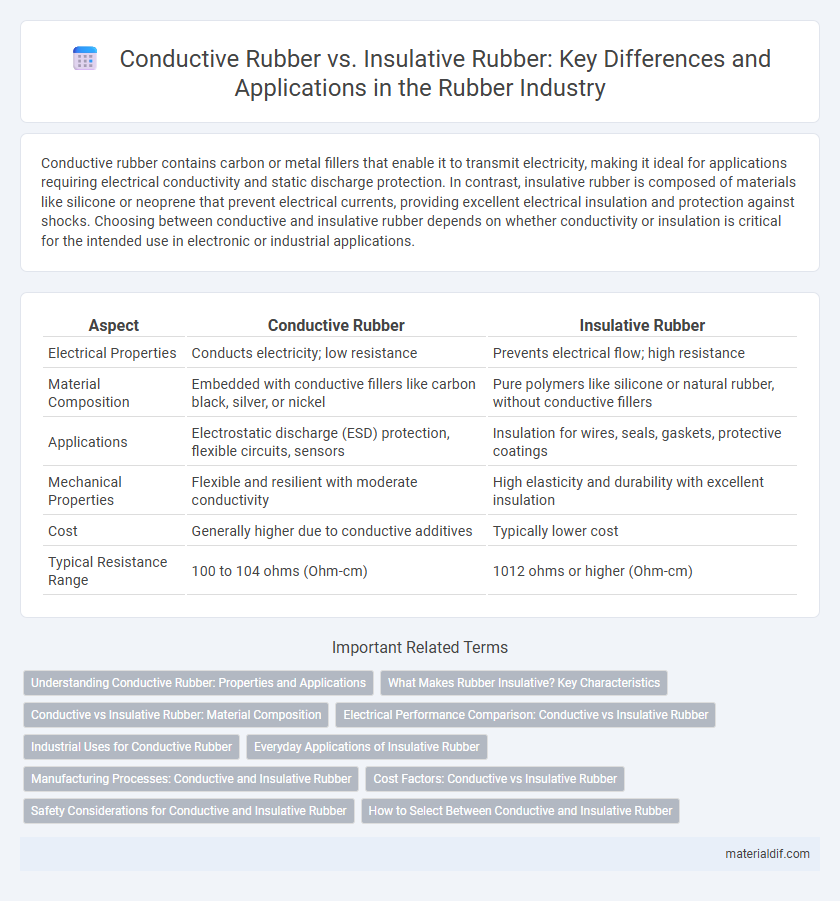

Table of Comparison

| Aspect | Conductive Rubber | Insulative Rubber |

|---|---|---|

| Electrical Properties | Conducts electricity; low resistance | Prevents electrical flow; high resistance |

| Material Composition | Embedded with conductive fillers like carbon black, silver, or nickel | Pure polymers like silicone or natural rubber, without conductive fillers |

| Applications | Electrostatic discharge (ESD) protection, flexible circuits, sensors | Insulation for wires, seals, gaskets, protective coatings |

| Mechanical Properties | Flexible and resilient with moderate conductivity | High elasticity and durability with excellent insulation |

| Cost | Generally higher due to conductive additives | Typically lower cost |

| Typical Resistance Range | 100 to 104 ohms (Ohm-cm) | 1012 ohms or higher (Ohm-cm) |

Understanding Conductive Rubber: Properties and Applications

Conductive rubber combines elastomeric materials with conductive fillers like carbon black or metal particles, enabling electrical conductivity while maintaining flexibility and durability. Its key properties include low electrical resistance, high elasticity, and resistance to wear, making it ideal for applications such as flexible sensors, EMI shielding, and flexible circuits. Common uses span wearable electronics, touchscreens, and grounding components, where traditional insulative rubber would fail to conduct electricity.

What Makes Rubber Insulative? Key Characteristics

Rubber's insulative properties stem from its molecular structure, which lacks free electrons, preventing electrical conductivity. Key characteristics of insulative rubber include high resistivity, excellent dielectric strength, and resistance to moisture and chemicals. This makes insulative rubber ideal for electrical insulation applications in cables, gloves, and protective coatings.

Conductive vs Insulative Rubber: Material Composition

Conductive rubber typically incorporates carbon black, metal particles, or conductive polymers within its elastomer matrix to enable electrical conductivity, making it suitable for applications like flexible circuits and sensors. In contrast, insulative rubber primarily consists of polymers such as silicone, neoprene, or EPDM, designed to prevent electrical current flow by maintaining high resistivity and dielectric strength. The specific material composition directly influences the rubber's electrical properties, thermal stability, and mechanical flexibility, determining its application in electronic, automotive, and industrial fields.

Electrical Performance Comparison: Conductive vs Insulative Rubber

Conductive rubber exhibits low electrical resistance, enabling efficient current flow critical for sensors, EMI shielding, and flexible electronics. In contrast, insulative rubber features high electrical resistance, providing excellent dielectric properties essential for insulation and protective coatings. The electrical performance differences dictate their applications, with conductive rubber facilitating conductivity and insulative rubber ensuring electrical isolation.

Industrial Uses for Conductive Rubber

Conductive rubber is extensively utilized in the electronics industry for its ability to transmit electrical signals while maintaining flexibility and durability, making it ideal for wearable devices and flexible circuit components. Its industrial applications include electromagnetic interference (EMI) shielding, touchscreen sensors, and conductive gaskets in automotive and aerospace systems. Conductive rubber composites, often embedded with carbon black or metal particles, optimize electrical conductivity without compromising mechanical resilience.

Everyday Applications of Insulative Rubber

Insulative rubber is widely used in everyday applications such as electrical gloves, cable coatings, and protective footwear, where preventing electrical conductivity is critical for safety. Its high resistance to electrical current makes it ideal for insulating wires, circuit boards, and electronic devices in household and industrial environments. The material's durability and flexibility also contribute to its essential role in insulating components from moisture, heat, and abrasion.

Manufacturing Processes: Conductive and Insulative Rubber

Conductive rubber is manufactured by incorporating conductive fillers such as carbon black, silver, or copper particles into the polymer matrix, enabling electrical conductivity through percolation pathways. Insulative rubber, in contrast, is produced using high-purity polymers like silicone or natural rubber without conductive additives, ensuring electrical resistance and dielectric properties. Advanced mixing techniques like extrusion and molding optimize filler dispersion and rubber homogeneity, crucial for achieving the desired electrical performance in both types.

Cost Factors: Conductive vs Insulative Rubber

Conductive rubber generally incurs higher costs compared to insulative rubber due to the incorporation of conductive fillers such as carbon black, silver, or copper particles, which increase raw material expenses. Manufacturing conductive rubber involves more complex processing techniques to ensure uniform dispersion of conductive additives, raising production costs relative to insulative rubber. Insulative rubber benefits from simpler formulations primarily composed of non-conductive polymers like silicone or natural rubber, making it more cost-effective for applications that do not require electrical conductivity.

Safety Considerations for Conductive and Insulative Rubber

Conductive rubber contains additives like carbon or metal particles to allow electrical current flow, making it essential to ensure proper grounding and avoid unintended short circuits for safety. Insulative rubber, composed primarily of silicone or neoprene without conductive fillers, provides excellent electrical insulation to prevent shock hazards in high-voltage environments. Selecting the appropriate type depends on application-specific safety requirements, such as preventing electrical interference or protecting users from electric shock.

How to Select Between Conductive and Insulative Rubber

Selecting between conductive and insulative rubber depends on the specific application requirements such as electrical conductivity, environmental conditions, and mechanical properties. Conductive rubber is ideal for applications requiring static dissipation, electromagnetic interference shielding, or grounding, often using materials like carbon or metal fillers to enhance conductivity. Insulative rubber is preferred for electrical insulation, protecting components from current leakage and ensuring safety, typically composed of silicone, EPDM, or natural rubber with high dielectric strength.

Conductive Rubber vs Insulative Rubber Infographic

materialdif.com

materialdif.com