Thermoplastic elastomers (TPE) offer superior flexibility and recyclability compared to thermoset rubber, making them ideal for applications requiring repeated deformation and environmental sustainability. Unlike thermoset rubber, which undergoes irreversible curing to form a rigid, cross-linked structure, TPEs can be melted and reshaped multiple times without losing their elastic properties. This reversible process not only reduces manufacturing waste but also enables easier customization and repair of rubber pet products.

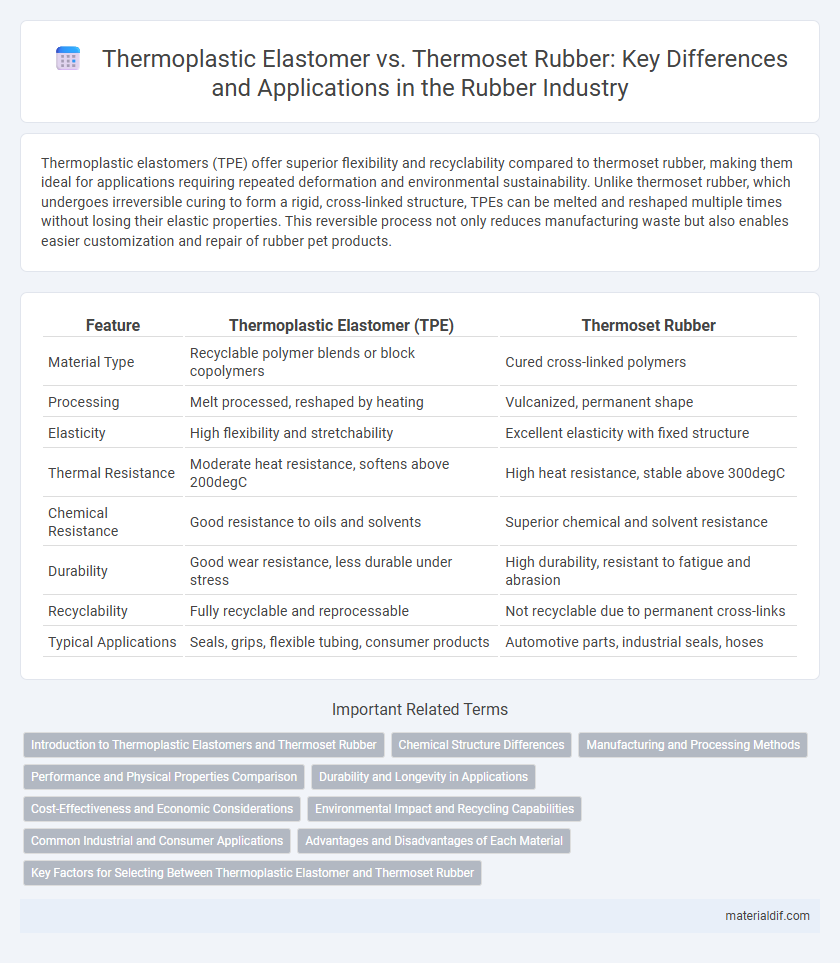

Table of Comparison

| Feature | Thermoplastic Elastomer (TPE) | Thermoset Rubber |

|---|---|---|

| Material Type | Recyclable polymer blends or block copolymers | Cured cross-linked polymers |

| Processing | Melt processed, reshaped by heating | Vulcanized, permanent shape |

| Elasticity | High flexibility and stretchability | Excellent elasticity with fixed structure |

| Thermal Resistance | Moderate heat resistance, softens above 200degC | High heat resistance, stable above 300degC |

| Chemical Resistance | Good resistance to oils and solvents | Superior chemical and solvent resistance |

| Durability | Good wear resistance, less durable under stress | High durability, resistant to fatigue and abrasion |

| Recyclability | Fully recyclable and reprocessable | Not recyclable due to permanent cross-links |

| Typical Applications | Seals, grips, flexible tubing, consumer products | Automotive parts, industrial seals, hoses |

Introduction to Thermoplastic Elastomers and Thermoset Rubber

Thermoplastic elastomers (TPEs) combine the elasticity of rubber with the recyclability of thermoplastics, featuring a distinct soft and hard segment microstructure that enables repeated melting and reshaping. Thermoset rubber undergoes a curing process forming irreversible cross-linked networks, resulting in superior heat resistance, mechanical strength, and chemical durability. The fundamental difference lies in TPEs' reversible physical bonds versus thermoset rubber's permanent covalent bonds, influencing their applications in automotive, medical, and consumer goods industries.

Chemical Structure Differences

Thermoplastic elastomers (TPEs) consist of linear or branched polymer chains without cross-linking, allowing them to soften upon heating and be reshaped. Thermoset rubber contains a three-dimensional network of covalently cross-linked polymer chains, providing permanent elasticity and resistance to melting. The chemical structure difference between TPEs and thermoset rubber fundamentally affects their thermal behavior, recyclability, and mechanical properties.

Manufacturing and Processing Methods

Thermoplastic elastomers (TPEs) undergo manufacturing through processes like injection molding, extrusion, and blow molding, allowing easy reheating and reshaping without chemical change. Thermoset rubber requires vulcanization, a curing process involving heat and sulfur or peroxide cross-linking that creates a permanent three-dimensional network, preventing remelting or reshaping. TPEs offer faster cycle times and greater recyclability in manufacturing, while thermoset rubber provides superior heat resistance and mechanical stability but involves longer processing due to irreversible curing.

Performance and Physical Properties Comparison

Thermoplastic elastomers (TPEs) exhibit superior flexibility and impact resistance compared to thermoset rubber, allowing for easier reshaping and recycling without significant loss of mechanical properties. Thermoset rubber offers enhanced thermal stability and chemical resistance due to its cross-linked molecular structure, resulting in higher durability under harsh environmental conditions. The choice between TPE and thermoset rubber depends on application requirements such as elasticity, temperature tolerance, and reprocessability.

Durability and Longevity in Applications

Thermoplastic elastomers (TPEs) offer flexibility and ease of recycling but generally exhibit lower durability and shorter lifespan compared to thermoset rubber, which provides superior chemical resistance and mechanical strength due to its cross-linked molecular structure. Thermoset rubber maintains structural integrity under high heat and stress, making it ideal for long-term, heavy-duty applications such as automotive seals and industrial gaskets. The enhanced longevity of thermoset rubber reduces maintenance costs and downtime in demanding environments where durability is critical.

Cost-Effectiveness and Economic Considerations

Thermoplastic elastomers (TPEs) offer greater cost-effectiveness than thermoset rubber due to their recyclability and faster processing times, reducing overall production expenses. Thermoset rubber involves higher initial material and curing costs but excels in durability and heat resistance, justifying its use in long-term, high-performance applications. Economic considerations favor TPEs for large-scale manufacturing with frequent design changes, while thermoset rubber remains preferable for products requiring superior mechanical properties and long service life.

Environmental Impact and Recycling Capabilities

Thermoplastic elastomers (TPEs) offer superior environmental benefits compared to thermoset rubber due to their recyclability and ability to be remelted without chemical degradation, enabling multiple recycling cycles. Thermoset rubbers undergo irreversible cross-linking during vulcanization, making them difficult to recycle and often resulting in landfill disposal or energy-intensive incineration. The recyclable nature of TPEs contributes to reduced carbon footprint and waste generation, positioning them as more sustainable alternatives in rubber manufacturing and applications.

Common Industrial and Consumer Applications

Thermoplastic elastomers (TPEs) commonly serve in automotive parts, medical devices, and consumer electronics due to their flexibility and recyclability, while thermoset rubbers excel in high-temperature seals, gaskets, and industrial hoses thanks to their superior heat resistance and durability. TPEs are favored in applications requiring frequent molding and reshaping, such as soft-touch grips and flexible tubing, whereas thermoset rubbers dominate in engine mounts and conveyor belts where permanent elasticity and mechanical strength are critical. The choice between TPE and thermoset rubber depends on the balance between reusability and long-term resilience in industries like automotive, healthcare, and consumer goods.

Advantages and Disadvantages of Each Material

Thermoplastic elastomers (TPEs) offer advantages such as recyclability, ease of processing, and the ability to be reshaped multiple times, making them ideal for applications requiring flexibility and rapid prototyping. Thermoset rubber provides superior heat resistance, mechanical strength, and chemical stability due to its crosslinked structure, but cannot be remolded or recycled once cured. TPEs may have limited thermal stability and lower chemical resistance compared to thermoset rubber, which often results in trade-offs between flexibility and durability depending on the application.

Key Factors for Selecting Between Thermoplastic Elastomer and Thermoset Rubber

Thermoplastic elastomers (TPEs) offer superior recyclability and ease of processing, making them ideal for applications requiring flexibility and repeated reshaping, whereas thermoset rubbers provide enhanced thermal stability, chemical resistance, and durability due to their cross-linked polymer structure. Key selection factors include end-use temperature tolerance, mechanical performance needs, environmental resistance, and lifecycle considerations such as recyclability and repairability. Cost implications also play a critical role, with thermosets generally preferred for high-performance, long-term applications and TPEs favored for cost-sensitive, flexible, and eco-friendly solutions.

Thermoplastic Elastomer vs Thermoset Rubber Infographic

materialdif.com

materialdif.com