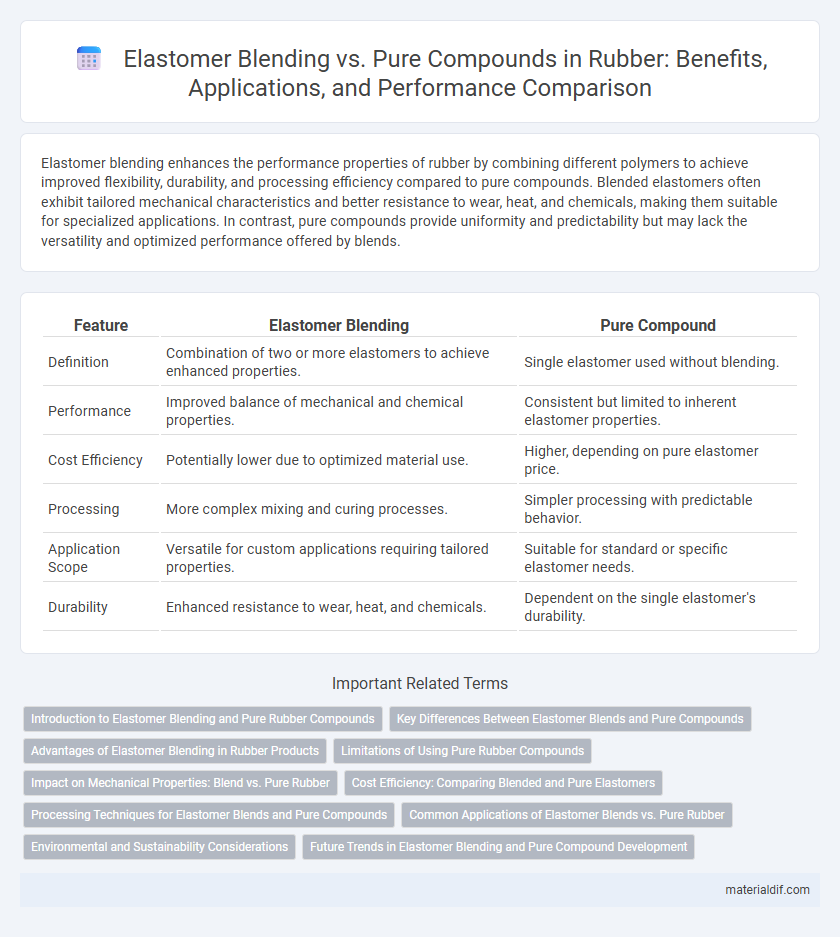

Elastomer blending enhances the performance properties of rubber by combining different polymers to achieve improved flexibility, durability, and processing efficiency compared to pure compounds. Blended elastomers often exhibit tailored mechanical characteristics and better resistance to wear, heat, and chemicals, making them suitable for specialized applications. In contrast, pure compounds provide uniformity and predictability but may lack the versatility and optimized performance offered by blends.

Table of Comparison

| Feature | Elastomer Blending | Pure Compound |

|---|---|---|

| Definition | Combination of two or more elastomers to achieve enhanced properties. | Single elastomer used without blending. |

| Performance | Improved balance of mechanical and chemical properties. | Consistent but limited to inherent elastomer properties. |

| Cost Efficiency | Potentially lower due to optimized material use. | Higher, depending on pure elastomer price. |

| Processing | More complex mixing and curing processes. | Simpler processing with predictable behavior. |

| Application Scope | Versatile for custom applications requiring tailored properties. | Suitable for standard or specific elastomer needs. |

| Durability | Enhanced resistance to wear, heat, and chemicals. | Dependent on the single elastomer's durability. |

Introduction to Elastomer Blending and Pure Rubber Compounds

Elastomer blending involves combining different types of rubbers to achieve a balance of properties such as tensile strength, elasticity, and chemical resistance, optimizing performance for specific applications. Pure rubber compounds consist of a single elastomer type, offering uniform characteristics but potentially limiting customization for specialized demands. Selecting between elastomer blends and pure compounds depends on the targeted mechanical properties, processability, and end-use environment requirements.

Key Differences Between Elastomer Blends and Pure Compounds

Elastomer blending combines two or more rubber types to optimize properties such as tensile strength, flexibility, and chemical resistance, whereas pure compounds consist of a single elastomer with uniform characteristics. Blends offer enhanced performance customization and cost efficiency by leveraging the synergistic effects of different polymers, while pure compounds ensure consistency and predictability for specialized applications. Processing behavior and cure rates also differ, with blends often requiring tailored vulcanization systems compared to the more straightforward cure profiles of pure elastomer compounds.

Advantages of Elastomer Blending in Rubber Products

Elastomer blending enhances the mechanical properties and chemical resistance of rubber products by combining complementary polymers, resulting in improved durability and flexibility. This approach optimizes processing characteristics such as moldability and cure rate, reducing production time and costs. Enhanced abrasion resistance and weatherability in blended elastomers extend product lifespan compared to pure compounds, driving superior performance in demanding applications.

Limitations of Using Pure Rubber Compounds

Pure rubber compounds often exhibit limitations such as reduced mechanical properties, poor processability, and lack of resistance to environmental factors like heat, ozone, and chemicals. These drawbacks restrict their application range and performance consistency compared to elastomer blends, which combine multiple polymers to enhance durability, flexibility, and overall functionality. The inability of pure rubber to achieve optimized physical and chemical characteristics without blending leads to compromises in product lifespan and operational efficiency.

Impact on Mechanical Properties: Blend vs. Pure Rubber

Elastomer blending improves mechanical properties by combining different polymers, enhancing tensile strength, abrasion resistance, and flexibility compared to pure rubber compounds. Blends tailor properties to specific applications, achieving better performance under stress and dynamic conditions. Pure rubber compounds often lack the versatility of blends, resulting in less optimized durability and mechanical resilience.

Cost Efficiency: Comparing Blended and Pure Elastomers

Elastomer blending offers significant cost efficiency by combining lower-cost base polymers with specialty elastomers to optimize performance and reduce material expenses. Pure elastomer compounds generally incur higher costs due to the exclusive use of specialty polymers, limiting flexibility in cost management. Blended elastomers enable manufacturers to tailor properties while maintaining budget control, making them a preferred choice for cost-sensitive applications.

Processing Techniques for Elastomer Blends and Pure Compounds

Processing techniques for elastomer blends involve specialized methods such as dynamic vulcanization and co-coagulation to achieve uniform dispersion and compatibility of multiple elastomers, enhancing properties like flexibility and chemical resistance. Pure compounds, in contrast, typically undergo standard mixing and molding processes including internal mixing and compression molding, focusing on consistent single-elastomer performance. Advanced techniques like twin-screw extrusion are often utilized in elastomer blending to improve the homogeneity and cure characteristics compared to pure compound processing.

Common Applications of Elastomer Blends vs. Pure Rubber

Elastomer blends are extensively used in automotive seals, industrial gaskets, and footwear soles due to their enhanced mechanical properties and resistance to chemicals and abrasion, offering versatility that pure rubber compounds often lack. Pure rubber compounds find applications in products requiring high elasticity and resilience such as balloons, adhesives, and damping elements, where uniform material properties are critical. The choice between elastomer blends and pure compounds depends on the specific performance requirements and environmental conditions of the application.

Environmental and Sustainability Considerations

Elastomer blending improves sustainability by enabling the use of recycled materials and reducing reliance on virgin rubber, lowering environmental impact through decreased waste and resource consumption. Pure compounds often require higher energy inputs and generate more production waste, making elastomer blends preferable for eco-friendly manufacturing. Optimizing blends enhances lifecycle performance and facilitates material recovery, supporting circular economy initiatives in the rubber industry.

Future Trends in Elastomer Blending and Pure Compound Development

Future trends in elastomer blending emphasize enhanced performance through combining multiple polymer types to create hybrid materials offering superior toughness, flexibility, and chemical resistance compared to pure compounds. Advanced technologies like reactive blending and nanocomposite integration are driving innovation toward tailored properties for specific industrial applications such as automotive tires and medical devices. Sustainable development is also a critical focus, with increased research in bio-based elastomers and recycling methods to reduce environmental impact while maintaining high performance standards.

Elastomer Blending vs Pure Compound Infographic

materialdif.com

materialdif.com