Rubber lining involves applying a thick, durable layer of rubber inside containers or pipes to protect against corrosion, abrasion, and chemical damage, ensuring long-term resistance and integrity. Rubber coating, on the other hand, offers a thinner, flexible layer applied to surfaces for enhanced grip, weatherproofing, and minor impact protection, suitable for less intensive environments. Choosing between rubber lining and rubber coating depends on the level of protection required and the specific industrial application.

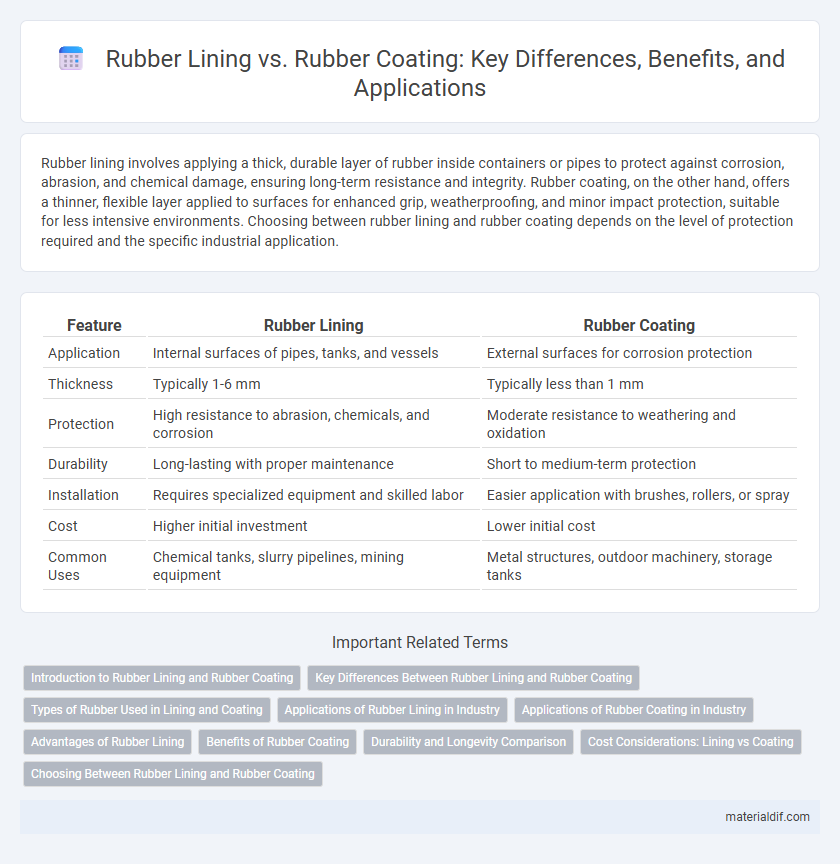

Table of Comparison

| Feature | Rubber Lining | Rubber Coating |

|---|---|---|

| Application | Internal surfaces of pipes, tanks, and vessels | External surfaces for corrosion protection |

| Thickness | Typically 1-6 mm | Typically less than 1 mm |

| Protection | High resistance to abrasion, chemicals, and corrosion | Moderate resistance to weathering and oxidation |

| Durability | Long-lasting with proper maintenance | Short to medium-term protection |

| Installation | Requires specialized equipment and skilled labor | Easier application with brushes, rollers, or spray |

| Cost | Higher initial investment | Lower initial cost |

| Common Uses | Chemical tanks, slurry pipelines, mining equipment | Metal structures, outdoor machinery, storage tanks |

Introduction to Rubber Lining and Rubber Coating

Rubber lining involves bonding a thick layer of natural or synthetic rubber to a surface, enhancing corrosion and abrasion resistance in industrial applications. Rubber coating is a thinner, sprayed or brushed-on layer that provides surface protection and improved grip but offers less durability compared to lining. Both methods extend equipment lifespan, with lining preferred for heavy-duty conditions and coating suited for lighter protection needs.

Key Differences Between Rubber Lining and Rubber Coating

Rubber lining involves the application of a thick, continuous layer of rubber to protect surfaces from corrosion, abrasion, and chemical damage, often used in industrial pipelines and tanks. Rubber coating, on the other hand, is a thinner layer applied primarily for surface protection and enhancement, offering flexibility and resistance against weathering and minor mechanical impacts. Key differences include thickness, durability, and application purpose, with rubber lining providing more robust protection in harsh environments compared to the more versatile and lighter protective rubber coating.

Types of Rubber Used in Lining and Coating

Rubber lining commonly utilizes natural rubber (NR) and chloroprene rubber (CR) due to their excellent abrasion resistance and chemical stability, making them ideal for protecting industrial equipment from corrosive substances. Rubber coating often employs synthetic rubbers like nitrile rubber (NBR) and ethylene propylene diene monomer (EPDM), which offer superior resistance to oils, fuels, and weathering for surface applications. Selection of rubber types depends on environmental exposure and mechanical demands, ensuring optimal durability and performance in lining versus coating applications.

Applications of Rubber Lining in Industry

Rubber lining offers superior chemical resistance and abrasion protection for industrial equipment handling corrosive substances, making it ideal for applications in chemical processing, mining, and wastewater treatment plants. Its thick, durable layers provide enhanced protection for tanks, pipes, and vessels exposed to harsh environments, extending equipment life significantly. Industries rely on rubber lining to safeguard infrastructure against acids, alkalis, and abrasive slurries, ensuring operational efficiency and reduced maintenance costs.

Applications of Rubber Coating in Industry

Rubber coating is widely used in industries for its excellent resistance to corrosion, abrasion, and chemical exposure, making it ideal for protecting metal surfaces in pipelines, tanks, and machinery. Its flexibility and waterproofing properties enhance durability in automotive, marine, and construction applications, preventing damage from environmental elements. Industries such as chemical manufacturing, mining, and waste management rely on rubber coatings to extend equipment lifespan and reduce maintenance costs.

Advantages of Rubber Lining

Rubber lining offers superior corrosion and abrasion resistance, making it ideal for protecting metal surfaces in harsh chemical environments and extending equipment lifespan. The seamless application of rubber lining ensures complete coverage, preventing leaks and enhancing durability compared to rubber coating. Its excellent impact absorption and flexibility reduce maintenance costs and downtime in industrial settings.

Benefits of Rubber Coating

Rubber coating provides enhanced protection against corrosion, abrasion, and chemical exposure, extending the lifespan of metal surfaces significantly. It offers a seamless, flexible barrier that prevents moisture ingress and resists UV damage, unlike traditional rubber lining which may involve seams and potential weak points. The application process of rubber coating is often more cost-effective and adaptable for complex shapes, making it ideal for industrial equipment maintenance and infrastructure protection.

Durability and Longevity Comparison

Rubber lining offers superior durability by providing a thick, seamless barrier resistant to abrasion, corrosion, and chemical attacks, significantly extending the lifespan of equipment in harsh industrial environments. Rubber coating, while easier to apply and more cost-effective, typically provides a thinner protective layer that may wear down faster under heavy mechanical stress and aggressive chemicals. Choosing rubber lining over coating enhances long-term asset protection and reduces maintenance costs, making it ideal for high-demand applications requiring maximum longevity.

Cost Considerations: Lining vs Coating

Rubber lining typically involves a higher initial investment due to the labor-intensive installation and thicker material application, but it offers superior durability and longer service life, reducing replacement frequency and long-term expenses. Rubber coating generally costs less upfront with easier application, making it suitable for budget-sensitive projects or temporary protection. Evaluating total cost of ownership, including maintenance and lifespan, is crucial when choosing between rubber lining and rubber coating solutions.

Choosing Between Rubber Lining and Rubber Coating

Rubber lining involves bonding a thick layer of rubber to the interior surface of equipment, providing superior chemical resistance and abrasion protection ideal for tanks and pipes handling corrosive substances. Rubber coating is a thinner application suited for surface protection and moisture resistance on external equipment or machinery exposed to environmental wear. Choosing between rubber lining and rubber coating depends on factors such as the type of exposure, required durability, and the specific chemical or mechanical stresses the surface will endure.

Rubber Lining vs Rubber Coating Infographic

materialdif.com

materialdif.com