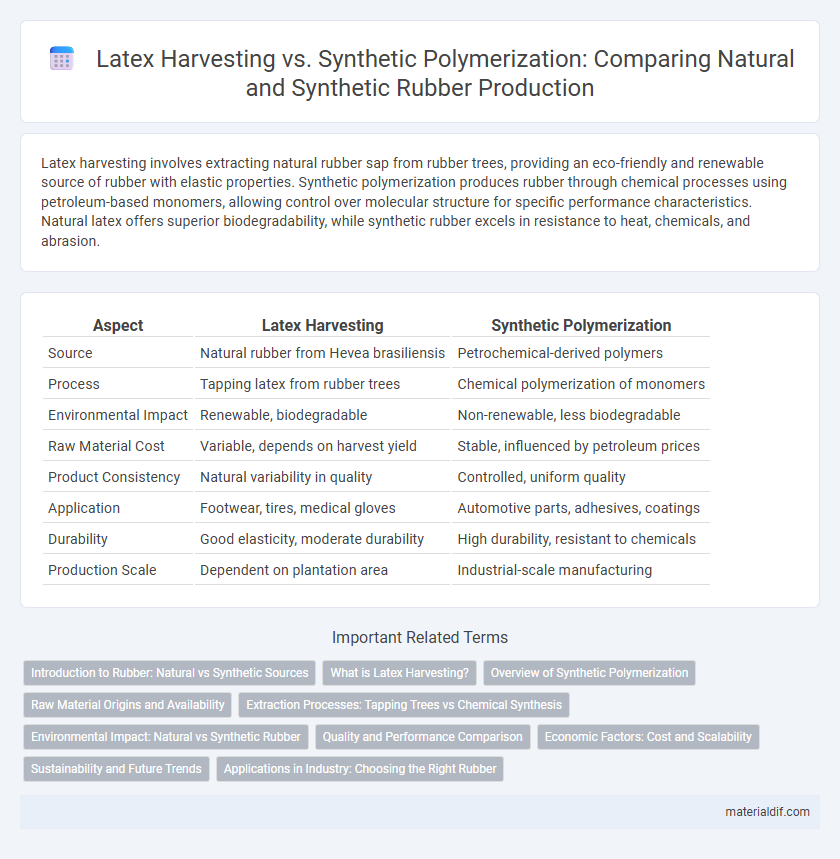

Latex harvesting involves extracting natural rubber sap from rubber trees, providing an eco-friendly and renewable source of rubber with elastic properties. Synthetic polymerization produces rubber through chemical processes using petroleum-based monomers, allowing control over molecular structure for specific performance characteristics. Natural latex offers superior biodegradability, while synthetic rubber excels in resistance to heat, chemicals, and abrasion.

Table of Comparison

| Aspect | Latex Harvesting | Synthetic Polymerization |

|---|---|---|

| Source | Natural rubber from Hevea brasiliensis | Petrochemical-derived polymers |

| Process | Tapping latex from rubber trees | Chemical polymerization of monomers |

| Environmental Impact | Renewable, biodegradable | Non-renewable, less biodegradable |

| Raw Material Cost | Variable, depends on harvest yield | Stable, influenced by petroleum prices |

| Product Consistency | Natural variability in quality | Controlled, uniform quality |

| Application | Footwear, tires, medical gloves | Automotive parts, adhesives, coatings |

| Durability | Good elasticity, moderate durability | High durability, resistant to chemicals |

| Production Scale | Dependent on plantation area | Industrial-scale manufacturing |

Introduction to Rubber: Natural vs Synthetic Sources

Natural rubber is sourced from latex, a milky fluid tapped primarily from Hevea brasiliensis trees through careful incisions that allow latex to flow without harming the tree. Synthetic rubber, in contrast, is produced via polymerization of petroleum-derived monomers such as butadiene or styrene, offering consistent quality and enhanced resistance to heat and chemicals. While natural latex harvesting depends on renewable biological resources and specific climatic conditions, synthetic polymerization relies on industrial processes that enable large-scale production independent of environmental factors.

What is Latex Harvesting?

Latex harvesting refers to the process of collecting natural latex, a milky fluid extracted from rubber trees (Hevea brasiliensis) through careful tapping of the bark. This natural latex contains polymers such as cis-1,4-polyisoprene, which are coagulated to produce natural rubber with high elasticity and resilience. Unlike synthetic polymerization, which creates rubber from petrochemical monomers like styrene and butadiene, latex harvesting relies on renewable biological sources and sustainable agricultural practices.

Overview of Synthetic Polymerization

Synthetic polymerization involves the chemical synthesis of rubber-like materials through the polymerization of monomers such as styrene and butadiene. This process allows for precise control over molecular structure, resulting in specific material properties tailored for diverse industrial applications including automotive tires, adhesives, and seals. Unlike latex harvesting from rubber trees, synthetic polymerization offers scalable production unaffected by agricultural variables and climate conditions.

Raw Material Origins and Availability

Latex harvesting sources natural rubber from Hevea brasiliensis trees, offering a renewable raw material with seasonal and geographic limitations primarily in tropical regions. Synthetic polymerization produces rubber from petrochemical derivatives like styrene and butadiene, ensuring consistent supply through industrial processes independent of climate conditions. Natural latex availability fluctuates with environmental factors, while synthetic rubber stability relies on global oil supply and refining capacities.

Extraction Processes: Tapping Trees vs Chemical Synthesis

Latex harvesting involves tapping rubber trees (Hevea brasiliensis) to extract natural latex, a renewable and biodegradable material collected through incisions in the bark. In contrast, synthetic polymerization produces synthetic rubber via chemical synthesis, primarily using petroleum-based monomers like styrene and butadiene in controlled industrial reactors. The extraction process for natural rubber emphasizes sustainability and natural resource management, whereas synthetic rubber relies on petrochemical feedstocks and complex catalytic reactions for polymer formation.

Environmental Impact: Natural vs Synthetic Rubber

Latex harvesting from Hevea brasiliensis trees offers a renewable, biodegradable source of natural rubber, minimizing environmental pollutants and supporting biodiversity in plantation ecosystems. In contrast, synthetic polymerization processes rely heavily on petroleum-based feedstocks, generating significant greenhouse gas emissions, non-biodegradable waste, and contributing to resource depletion. The environmental footprint of synthetic rubber production is substantially higher compared to sustainable latex extraction, making natural rubber the more eco-friendly alternative.

Quality and Performance Comparison

Natural latex harvested from rubber trees offers superior elasticity, resilience, and biodegradability compared to synthetic polymers produced through chemical polymerization. Synthetic rubber, while versatile and resistant to temperature and chemical degradation, often lacks the fine molecular uniformity of natural latex, impacting its tactile quality and tensile strength. The choice between latex harvesting and synthetic polymerization hinges on desired application properties, with natural latex preferred for comfort and sustainability, and synthetic rubber favored for durability and specialized industrial use.

Economic Factors: Cost and Scalability

Latex harvesting from rubber trees requires significant labor and land, leading to higher initial costs but benefits from natural renewability and market demand for sustainable products. Synthetic polymerization involves large-scale industrial processes with high energy inputs but offers greater scalability and consistent raw material supply at potentially lower unit costs. Economic viability depends on balancing labor-intensive cultivation expenses against the capital-intensive infrastructure of synthetic production.

Sustainability and Future Trends

Latex harvesting from Hevea brasiliensis trees remains a renewable source of natural rubber with low carbon emissions and biodegradability, promoting a circular economy. Synthetic polymerization of rubber, primarily derived from petrochemicals, offers scalability but raises concerns over fossil fuel depletion and environmental pollution. Advances in bio-based synthetic alternatives and improved plantation management are driving sustainable innovations in the rubber industry's future.

Applications in Industry: Choosing the Right Rubber

Latex harvesting produces natural rubber prized for its elasticity and resilience, making it ideal for medical gloves, tires, and adhesives. Synthetic polymerization creates synthetic rubber types like styrene-butadiene and nitrile rubber, which offer enhanced chemical resistance and durability for automotive parts, seals, and hoses. Selecting between natural and synthetic rubber depends on specific industrial applications requiring either biocompatibility or resistance to harsh environments.

Latex Harvesting vs Synthetic Polymerization Infographic

materialdif.com

materialdif.com