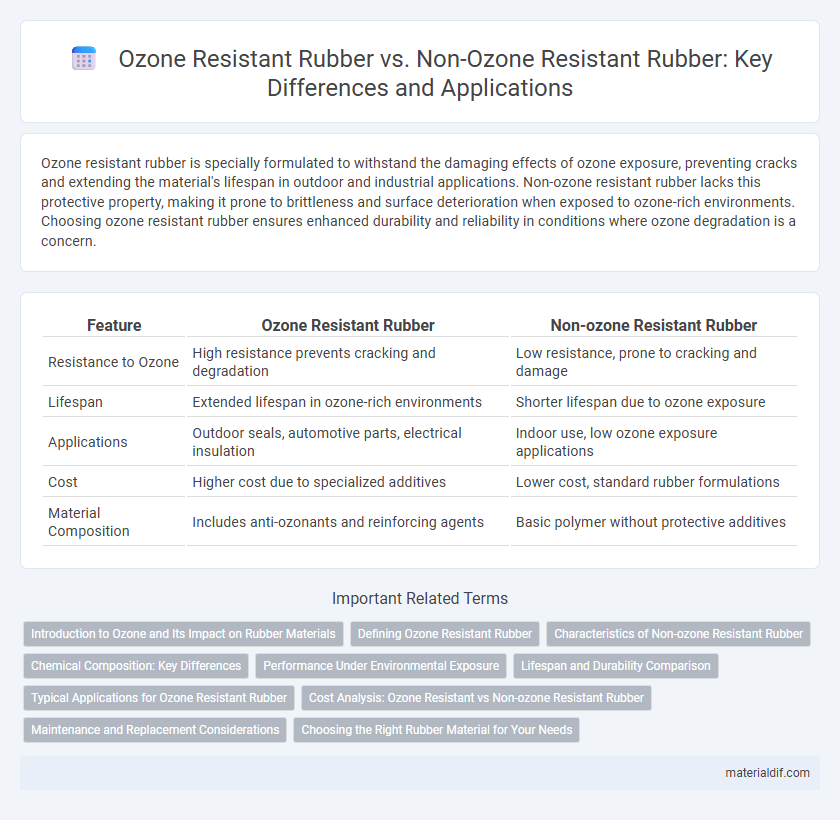

Ozone resistant rubber is specially formulated to withstand the damaging effects of ozone exposure, preventing cracks and extending the material's lifespan in outdoor and industrial applications. Non-ozone resistant rubber lacks this protective property, making it prone to brittleness and surface deterioration when exposed to ozone-rich environments. Choosing ozone resistant rubber ensures enhanced durability and reliability in conditions where ozone degradation is a concern.

Table of Comparison

| Feature | Ozone Resistant Rubber | Non-ozone Resistant Rubber |

|---|---|---|

| Resistance to Ozone | High resistance prevents cracking and degradation | Low resistance, prone to cracking and damage |

| Lifespan | Extended lifespan in ozone-rich environments | Shorter lifespan due to ozone exposure |

| Applications | Outdoor seals, automotive parts, electrical insulation | Indoor use, low ozone exposure applications |

| Cost | Higher cost due to specialized additives | Lower cost, standard rubber formulations |

| Material Composition | Includes anti-ozonants and reinforcing agents | Basic polymer without protective additives |

Introduction to Ozone and Its Impact on Rubber Materials

Ozone is a reactive gas that causes significant degradation in rubber materials by initiating cracks through oxidative stress, particularly when exposed to atmospheric conditions. Ozone resistant rubber contains chemical additives and polymer structures designed to inhibit this damage, maintaining flexibility and durability over time. Non-ozone resistant rubber, lacking these protective features, rapidly deteriorates, leading to compromised mechanical properties and shortened service life.

Defining Ozone Resistant Rubber

Ozone resistant rubber is a type of synthetic rubber specifically formulated to withstand degradation caused by ozone exposure, which causes cracking and loss of elasticity in ordinary rubber materials. This rubber contains additives such as antiozonants that form a protective barrier, preventing ozone molecules from attacking the polymer chains. In comparison, non-ozone resistant rubber lacks these stabilizers and is prone to surface cracks and accelerated aging when exposed to ozone-rich environments.

Characteristics of Non-ozone Resistant Rubber

Non-ozone resistant rubber typically exhibits poor durability when exposed to atmospheric ozone, leading to surface cracks, reduced elasticity, and premature failure. This type of rubber lacks protective additives that prevent ozone degradation, causing brittleness and loss of mechanical integrity under ozone stress. Common non-ozone resistant rubbers include natural rubber and certain synthetic rubbers like styrene-butadiene rubber (SBR), which are prone to ozone cracking in outdoor or industrial environments.

Chemical Composition: Key Differences

Ozone resistant rubber typically contains antiozonants such as para-phenylenediamine compounds and specialized polymers like EPDM (ethylene propylene diene monomer) that enhance its ability to withstand ozone degradation. Non-ozone resistant rubber, often made from natural rubber or standard SBR (styrene-butadiene rubber), lacks these protective chemical additives, making it susceptible to cracking and brittleness when exposed to ozone. The molecular structure of ozone resistant rubber includes stabilized double bonds or saturated backbones, unlike the unsaturated bonds in non-ozone resistant variants that react easily with ozone molecules.

Performance Under Environmental Exposure

Ozone resistant rubber maintains its mechanical integrity and elasticity when exposed to ozone, preventing cracks and surface deterioration common in non-ozone resistant rubber. This enhanced durability under environmental stress extends the lifespan of products used in outdoor applications such as seals, hoses, and gaskets. In contrast, non-ozone resistant rubber exhibits premature aging, brittleness, and performance decline due to ozone-induced oxidative degradation.

Lifespan and Durability Comparison

Ozone resistant rubber exhibits significantly enhanced lifespan and durability compared to non-ozone resistant rubber, as it resists cracking and degradation caused by ozone exposure. This resistance prevents premature material failure in outdoor and industrial applications, extending service life by years. Non-ozone resistant rubber often suffers from surface cracks and brittleness, leading to frequent replacements and increased maintenance costs.

Typical Applications for Ozone Resistant Rubber

Ozone resistant rubber is commonly used in outdoor automotive parts, electrical insulation, and protective seals where exposure to ozone and UV radiation can cause cracking and deterioration. Its applications include weatherstripping, gaskets, and hoses in vehicles, as well as conveyor belts and cable jackets in industrial settings. This type of rubber ensures long-lasting performance in environments subject to ozone exposure, outperforming non-ozone resistant variants.

Cost Analysis: Ozone Resistant vs Non-ozone Resistant Rubber

Ozone resistant rubber typically incurs higher initial costs compared to non-ozone resistant rubber due to specialized additives that enhance durability against ozone degradation. However, the long-term maintenance and replacement expenses for non-ozone resistant rubber often surpass the upfront investment in ozone resistant variants. Evaluating total cost of ownership reveals that ozone resistant rubber offers better economic efficiency in applications exposed to ozone-prone environments.

Maintenance and Replacement Considerations

Ozone resistant rubber exhibits superior durability in harsh environments, significantly reducing the frequency of maintenance and the need for premature replacement due to cracking and surface degradation. Non-ozone resistant rubber often requires frequent inspections and early replacement as it quickly deteriorates when exposed to ozone-rich conditions. Choosing ozone resistant rubber improves long-term cost efficiency and operational reliability by minimizing downtime and maintenance expenses.

Choosing the Right Rubber Material for Your Needs

Ozone resistant rubber, such as EPDM and certain nitrile blends, offers superior durability against cracking and degradation caused by ozone exposure, making it ideal for outdoor and industrial applications. Non-ozone resistant rubber varieties, like natural rubber and some polybutadiene compounds, can deteriorate quickly when exposed to ozone, limiting their use to indoor or low-ozone environments. Selecting the right rubber material depends on considering environmental factors and the specific performance requirements to ensure longevity and cost-effectiveness.

Ozone Resistant Rubber vs Non-ozone Resistant Rubber Infographic

materialdif.com

materialdif.com