Solid rubber offers superior durability and resistance to abrasion, making it ideal for heavy-duty applications requiring long-lasting performance. Sponge rubber, characterized by its cellular structure, provides excellent cushioning, flexibility, and impact absorption, suitable for sealing and vibration-damping uses. Choosing between solid and sponge rubber depends on the specific demands for resilience versus compressibility in the intended application.

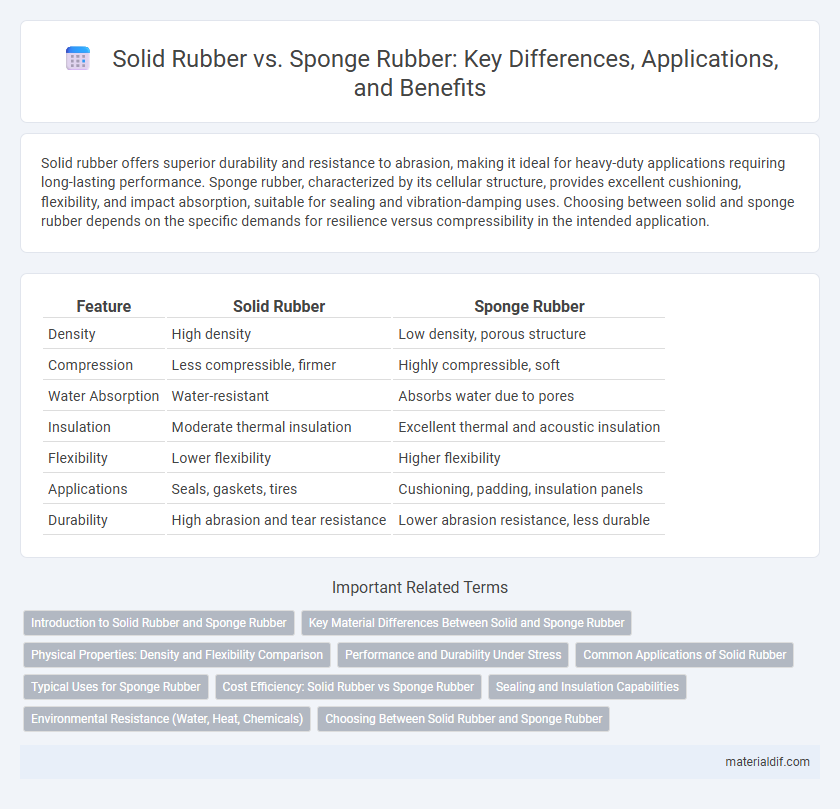

Table of Comparison

| Feature | Solid Rubber | Sponge Rubber |

|---|---|---|

| Density | High density | Low density, porous structure |

| Compression | Less compressible, firmer | Highly compressible, soft |

| Water Absorption | Water-resistant | Absorbs water due to pores |

| Insulation | Moderate thermal insulation | Excellent thermal and acoustic insulation |

| Flexibility | Lower flexibility | Higher flexibility |

| Applications | Seals, gaskets, tires | Cushioning, padding, insulation panels |

| Durability | High abrasion and tear resistance | Lower abrasion resistance, less durable |

Introduction to Solid Rubber and Sponge Rubber

Solid rubber exhibits high density and durability, making it ideal for heavy-duty applications requiring resistance to abrasion and punctures. Sponge rubber features a cellular structure with trapped air pockets, resulting in a lightweight, cushioning material commonly used for insulation and shock absorption. Both types serve distinct roles in industries ranging from automotive to footwear, driven by their unique physical properties.

Key Material Differences Between Solid and Sponge Rubber

Solid rubber is dense and non-porous, providing high durability, excellent abrasion resistance, and strong mechanical properties suitable for heavy-duty applications. Sponge rubber features a cellular structure with trapped air pockets, resulting in a lightweight, flexible material with good cushioning, thermal insulation, and sound absorption characteristics. The key material differences lie in density, elasticity, and permeability, where solid rubber excels in strength and wear resistance, while sponge rubber offers enhanced shock absorption and compressibility.

Physical Properties: Density and Flexibility Comparison

Solid rubber typically exhibits higher density ranging from 1.1 to 1.5 g/cm3, providing greater durability and resistance to wear. Sponge rubber, characterized by a cellular structure, has lower density values around 0.3 to 0.7 g/cm3, which enhances flexibility and cushioning properties. The inherent flexibility in sponge rubber makes it ideal for applications requiring impact absorption, whereas solid rubber's rigidity suits load-bearing and abrasion-resistant uses.

Performance and Durability Under Stress

Solid rubber exhibits superior durability under high-stress conditions due to its dense, compact molecular structure, which resists deformation and wear more effectively than sponge rubber. Sponge rubber, characterized by its cellular, porous makeup, offers enhanced flexibility and shock absorption but tends to compress and deteriorate faster when exposed to continuous heavy loads or abrasive environments. Performance-wise, solid rubber is ideal for applications requiring long-lasting resilience and resistance to mechanical stress, whereas sponge rubber excels in cushioning and vibration isolation but sacrifices some longevity under intense pressure.

Common Applications of Solid Rubber

Solid rubber is widely used in applications requiring high durability and resistance to wear, such as conveyor belts, industrial gaskets, and heavy-duty tires. Its dense composition makes it ideal for automotive mounts, vibration dampening pads, and protective bumpers in machinery. Solid rubber's robustness also suits it for use in seals, hoses, and flooring in industrial environments.

Typical Uses for Sponge Rubber

Sponge rubber, characterized by its cellular structure and enhanced cushioning properties, is commonly used in sealing, gasketing, and shock absorption applications where flexibility and compression recovery are essential. It is ideal for automotive door and window seals, weather stripping, and vibration dampening pads due to its ability to conform to irregular surfaces and resist water and air infiltration. Typical industries utilizing sponge rubber include automotive, construction, and electronics, where reliable insulation and noise reduction are critical.

Cost Efficiency: Solid Rubber vs Sponge Rubber

Solid rubber offers greater cost efficiency due to its durability and longer lifespan, reducing the frequency of replacement in industrial applications. Sponge rubber, while generally less expensive initially, tends to wear out faster and may incur higher maintenance costs over time. Choosing solid rubber often results in lower total cost of ownership despite a higher upfront price.

Sealing and Insulation Capabilities

Solid rubber provides superior sealing capabilities due to its dense, non-porous structure, effectively preventing fluid and air leaks in industrial applications. Sponge rubber, with its cellular, porous composition, excels in insulation by trapping air within its structure, enhancing thermal and acoustic resistance. Both materials offer distinct advantages depending on the specific sealing or insulation requirements, with solid rubber favored for durability and sponge rubber preferred for cushioning and energy absorption.

Environmental Resistance (Water, Heat, Chemicals)

Solid rubber exhibits superior environmental resistance, offering excellent durability against water, heat, and a broad range of chemicals, making it ideal for harsh industrial applications. Sponge rubber, with its porous structure, demonstrates lower resistance to water absorption and chemical exposure but provides better cushioning and flexibility. Heat resistance varies by formulation, but solid rubber generally maintains integrity at higher temperatures, whereas sponge rubber may degrade faster under intense thermal stress.

Choosing Between Solid Rubber and Sponge Rubber

Choosing between solid rubber and sponge rubber depends on application-specific factors such as durability, cushioning, and environmental exposure. Solid rubber offers superior abrasion resistance and load-bearing capacity, making it ideal for heavy-duty uses like industrial seals and wheels. Sponge rubber provides excellent shock absorption and insulation due to its porous structure, suitable for cushioning, sealing, and vibration dampening in automotive or packaging industries.

Solid Rubber vs Sponge Rubber Infographic

materialdif.com

materialdif.com