Buna-N (Nitrile) and Buna-S (Styrene-Butadiene) are two popular synthetic rubbers known for their distinct properties and applications. Buna-N offers superior resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial seals, while Buna-S provides excellent abrasion resistance and tensile strength, suitable for tire manufacturing and mechanical goods. Choosing between Buna-N and Buna-S depends on the specific environmental exposure and mechanical demands of the intended use.

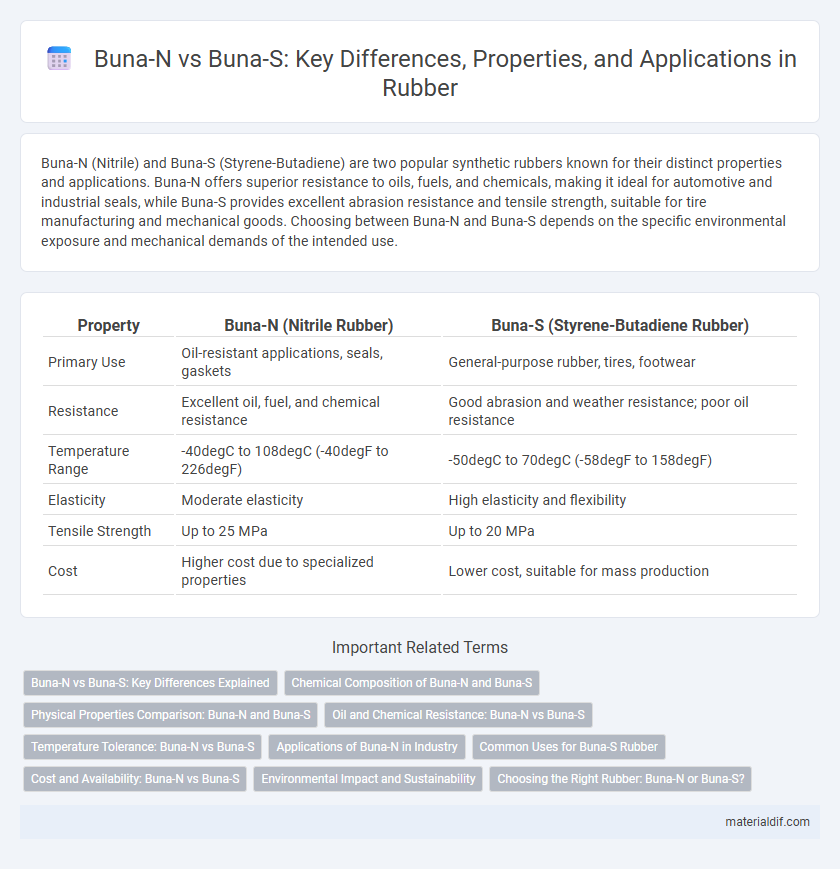

Table of Comparison

| Property | Buna-N (Nitrile Rubber) | Buna-S (Styrene-Butadiene Rubber) |

|---|---|---|

| Primary Use | Oil-resistant applications, seals, gaskets | General-purpose rubber, tires, footwear |

| Resistance | Excellent oil, fuel, and chemical resistance | Good abrasion and weather resistance; poor oil resistance |

| Temperature Range | -40degC to 108degC (-40degF to 226degF) | -50degC to 70degC (-58degF to 158degF) |

| Elasticity | Moderate elasticity | High elasticity and flexibility |

| Tensile Strength | Up to 25 MPa | Up to 20 MPa |

| Cost | Higher cost due to specialized properties | Lower cost, suitable for mass production |

Buna-N vs Buna-S: Key Differences Explained

Buna-N (Nitrile rubber) offers superior resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial seals, while Buna-S (Styrene-butadiene rubber) excels in abrasion resistance and flexibility, commonly used in footwear and tires. The key difference lies in Buna-N's nitrile content, providing enhanced oil resistance, whereas Buna-S contains styrene units that improve durability against mechanical wear. Temperature tolerance varies, with Buna-N maintaining performance between -40degC and 120degC, while Buna-S operates effectively from -50degC to 100degC, influencing their application suitability.

Chemical Composition of Buna-N and Buna-S

Buna-N, also known as nitrile rubber, is composed primarily of acrylonitrile and butadiene, offering excellent resistance to oils and fuels. Buna-S, or styrene-butadiene rubber (SBR), consists mainly of styrene and butadiene, providing good abrasion resistance and aging stability. The higher acrylonitrile content in Buna-N enhances chemical resistance, whereas Buna-S's styrene content contributes to its flexibility and durability.

Physical Properties Comparison: Buna-N and Buna-S

Buna-N (Nitrile) rubber exhibits excellent resistance to oils, fuels, and aliphatic hydrocarbons, with a tensile strength ranging from 15 to 30 MPa and elongation at break between 300-600%. Buna-S (Styrene-Butadiene), known for superior abrasion resistance and aging stability, typically shows tensile strength between 15 to 25 MPa and elongation at break of 400-600%. The hardness of Buna-N usually spans 40-90 Shore A, while Buna-S often falls within 50-80 Shore A, making Buna-N more suitable for applications involving oil exposure and Buna-S ideal for rubber goods requiring increased wear resistance.

Oil and Chemical Resistance: Buna-N vs Buna-S

Buna-N (Nitrile) rubber offers excellent oil and fuel resistance, making it ideal for applications involving petroleum products, hydraulic fluids, and aliphatic hydrocarbons. Buna-S (Styrene-Butadiene) rubber exhibits lower resistance to oils and chemicals but performs well against abrasion and weathering. For environments with intense exposure to oils and chemicals, Buna-N provides superior durability compared to Buna-S.

Temperature Tolerance: Buna-N vs Buna-S

Buna-N (Nitrile) rubber typically withstands temperatures ranging from -40degC to 108degC, making it suitable for applications involving moderate heat exposure. Buna-S (Styrene-butadiene) has a narrower temperature tolerance, usually between -50degC and 70degC, limiting its use in higher-temperature environments. The superior heat resistance of Buna-N makes it preferable for sealing and gasket applications in automotive and industrial machinery operating at elevated temperatures.

Applications of Buna-N in Industry

Buna-N, also known as Nitrile Rubber, is extensively used in the automotive and aerospace industries due to its superior resistance to oils, fuels, and chemicals. It is the preferred material for manufacturing fuel hoses, gaskets, seals, and O-rings that require durability under harsh conditions. Compared to Buna-S, Buna-N offers enhanced performance in environments involving petroleum-based fluids and higher temperature thresholds.

Common Uses for Buna-S Rubber

Buna-S rubber, also known as styrene-butadiene rubber (SBR), is widely used in manufacturing automotive tires, conveyor belts, and shoe soles due to its excellent abrasion resistance and aging stability. Its common applications extend to gaskets, seals, and hoses in industrial settings where moderate heat and chemical resistance are required. Compared to Buna-N, Buna-S offers better wear resistance but lower oil and chemical resistance, making it ideal for dynamic mechanical uses rather than exposure to fuels or oils.

Cost and Availability: Buna-N vs Buna-S

Buna-N (Nitrile) rubber is generally more cost-effective and widely available than Buna-S (Styrene-butadiene) rubber, making it the preferred choice for applications requiring oil and fuel resistance. Buna-N's production volume and established supply chains contribute to lower prices and easier procurement compared to Buna-S, which is less commonly used and often reserved for specific applications like tire manufacturing. Cost efficiency and accessibility of Buna-N enhance its appeal in industrial sealing and automotive industries where budget constraints are critical.

Environmental Impact and Sustainability

Buna-N (Nitrile) rubber offers superior resistance to petroleum-based oils and fuels, making it more suitable for industrial applications with lower environmental degradation risk. Buna-S (Styrene-butadiene) rubber, derived from petrochemicals, is less resistant to oil but boasts greater recyclability and biodegradability, contributing to reduced environmental footprint. Selecting Buna-N versus Buna-S depends on balancing durability requirements with sustainability goals, especially in industries prioritizing eco-friendly materials and waste reduction.

Choosing the Right Rubber: Buna-N or Buna-S?

Buna-N (Nitrile) offers superior resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial applications requiring high durability and temperature resistance up to 100degC. Buna-S (Styrene-Butadiene) excels in abrasion resistance and flexibility, suited for general-purpose seals and gaskets where resilience and weather resistance are needed, but exposure to oils is minimal. Selecting the right rubber hinges on the specific environment and performance requirements, with Buna-N favored for oil-heavy applications and Buna-S preferred when abrasion and wear resistance are critical.

Buna-N vs Buna-S Infographic

materialdif.com

materialdif.com