Raw rubber is a natural polymer harvested from rubber trees, known for its high elasticity and tackiness but lacks durability and resistance to heat and chemicals. Cured rubber undergoes a vulcanization process that cross-links polymer chains, significantly enhancing its strength, elasticity, and stability for various industrial applications. The choice between raw and cured rubber depends on the required mechanical properties and environmental resistance needed for the specific use.

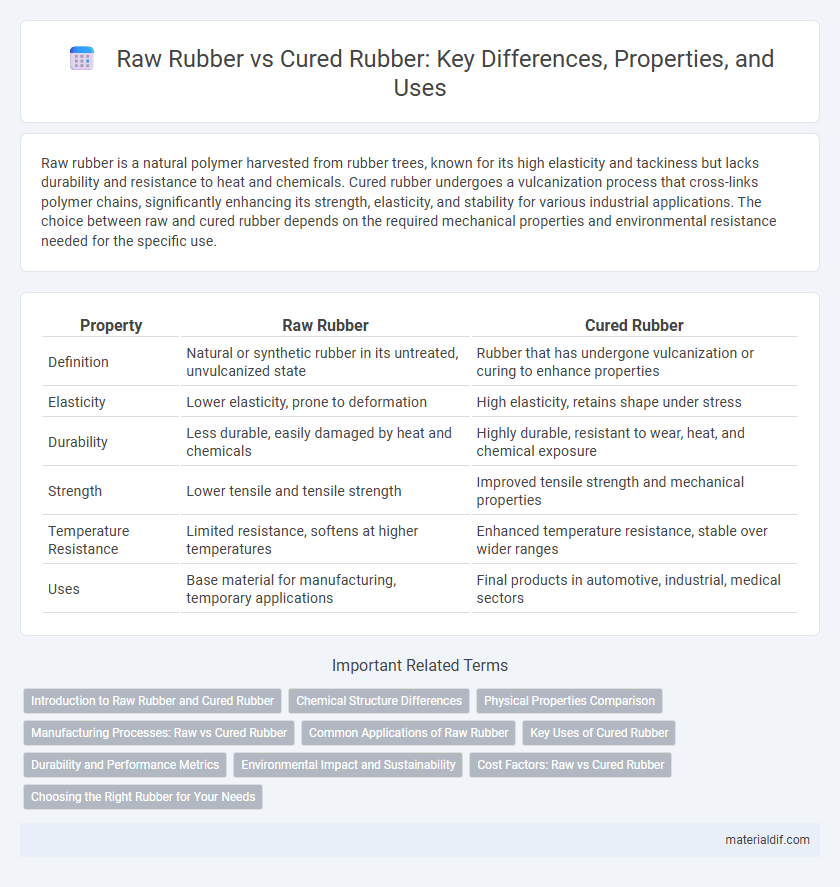

Table of Comparison

| Property | Raw Rubber | Cured Rubber |

|---|---|---|

| Definition | Natural or synthetic rubber in its untreated, unvulcanized state | Rubber that has undergone vulcanization or curing to enhance properties |

| Elasticity | Lower elasticity, prone to deformation | High elasticity, retains shape under stress |

| Durability | Less durable, easily damaged by heat and chemicals | Highly durable, resistant to wear, heat, and chemical exposure |

| Strength | Lower tensile and tensile strength | Improved tensile strength and mechanical properties |

| Temperature Resistance | Limited resistance, softens at higher temperatures | Enhanced temperature resistance, stable over wider ranges |

| Uses | Base material for manufacturing, temporary applications | Final products in automotive, industrial, medical sectors |

Introduction to Raw Rubber and Cured Rubber

Raw rubber, also known as natural rubber, is an elastomer harvested from the latex sap of rubber trees, exhibiting high elasticity and plasticity in its untreated state. Cured rubber undergoes vulcanization, a chemical process that cross-links polymer chains to improve durability, elasticity, and resistance to heat and chemicals. Understanding the differences between raw and cured rubber is essential for applications in industries such as automotive tires, medical devices, and adhesives.

Chemical Structure Differences

Raw rubber primarily consists of cis-1,4-polyisoprene with a high degree of unsaturation, which results in flexible, tacky material prone to oxidation and degradation. Cured rubber undergoes cross-linking through vulcanization, forming sulfur bridges between polyisoprene chains, significantly enhancing tensile strength, elasticity, and chemical resistance. The chemical structure transformation from linear to cross-linked polymers is key to the durability and performance improvements in cured rubber products.

Physical Properties Comparison

Raw rubber exhibits high elasticity and tackiness with low tensile strength and poor weather resistance, making it highly flexible but prone to deformation. Cured rubber undergoes vulcanization, which significantly enhances its tensile strength, abrasion resistance, and thermal stability while reducing elasticity. The curing process also improves resilience against chemicals, ozone, and aging, resulting in superior durability compared to raw rubber.

Manufacturing Processes: Raw vs Cured Rubber

Raw rubber, also known as natural rubber, is harvested latex that undergoes minimal processing and retains its sticky, elastic properties; it is primarily used as the base material in manufacturing. Cured rubber, however, undergoes vulcanization, a chemical process involving heat and sulfur that enhances its elasticity, durability, and resistance to heat and chemicals, making it suitable for final products like tires and seals. The manufacturing process differences between raw and cured rubber define their applications, with raw rubber serving as the initial input and cured rubber providing the finished material with targeted mechanical properties.

Common Applications of Raw Rubber

Raw rubber, characterized by its natural elasticity and tackiness, is commonly used in adhesives, protective coatings, and as an intermediate material in rubber product manufacturing. Its high tensile strength and flexibility make it ideal for applications like rubber bands, gaskets, and seals that require durability and resilience. Industries such as automotive, footwear, and construction frequently utilize raw rubber for producing components that undergo further processing or curing.

Key Uses of Cured Rubber

Cured rubber is extensively utilized in automotive tires, industrial belts, and seals due to its enhanced durability and elasticity. Its cross-linked structure provides superior resistance to heat, chemicals, and abrasion compared to raw rubber. This makes cured rubber indispensable in manufacturing products that require long-term performance and safety.

Durability and Performance Metrics

Raw rubber exhibits high elasticity but lacks the durability and resistance needed for most industrial applications, often degrading under heat, ozone, and mechanical stress. Cured rubber undergoes vulcanization, enhancing tensile strength, abrasion resistance, and heat tolerance, resulting in superior longevity and consistent performance in demanding environments. Performance metrics such as Shore hardness, tensile strength (MPa), and elongation at break (%) significantly improve post-curing, making cured rubber ideal for automotive tires, seals, and industrial products.

Environmental Impact and Sustainability

Raw rubber, harvested directly from rubber trees, demonstrates a lower environmental footprint due to minimal processing and biodegradability, supporting sustainable forestry practices when sourced responsibly. Cured rubber, subjected to vulcanization and chemical treatments, often involves energy-intensive processes and introduces non-biodegradable components, posing challenges for recycling and long-term environmental impact. Sustainable initiatives focus on improving raw rubber extraction methods and developing eco-friendly curing technologies to reduce carbon emissions and enhance circularity in the rubber industry.

Cost Factors: Raw vs Cured Rubber

Raw rubber generally incurs lower initial costs due to minimal processing requirements, but its quality and durability limitations often lead to higher long-term expenses. Cured rubber, involving vulcanization and additional treatments, demands increased manufacturing costs but offers enhanced strength, elasticity, and lifespan, justifying the upfront investment. Variations in raw material sourcing, energy consumption, and labor intensity significantly influence the overall cost disparity between raw and cured rubber products.

Choosing the Right Rubber for Your Needs

Raw rubber offers high elasticity and tackiness essential for products requiring flexibility and adhesion, while cured rubber provides enhanced durability, heat resistance, and chemical stability suitable for long-term applications. Selecting the right rubber depends on the specific requirements such as mechanical strength, environmental exposure, and lifespan of the product. Understanding these properties ensures optimal performance in industries like automotive, manufacturing, and consumer goods.

Raw Rubber vs Cured Rubber Infographic

materialdif.com

materialdif.com